Selenium-rich rhizoma polygonati medicinal material and processing technology thereof

A processing technology and technology of Polygonatum chinensis, which are applied in the field of selenium-enriched Polygonatum chinensis medicinal materials and the processing technology thereof, can solve the problems of unfavorable product promotion, long production cycle and high production cost, and achieve a product suitable for long-term administration, shortened processing cycle and increased selenium content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

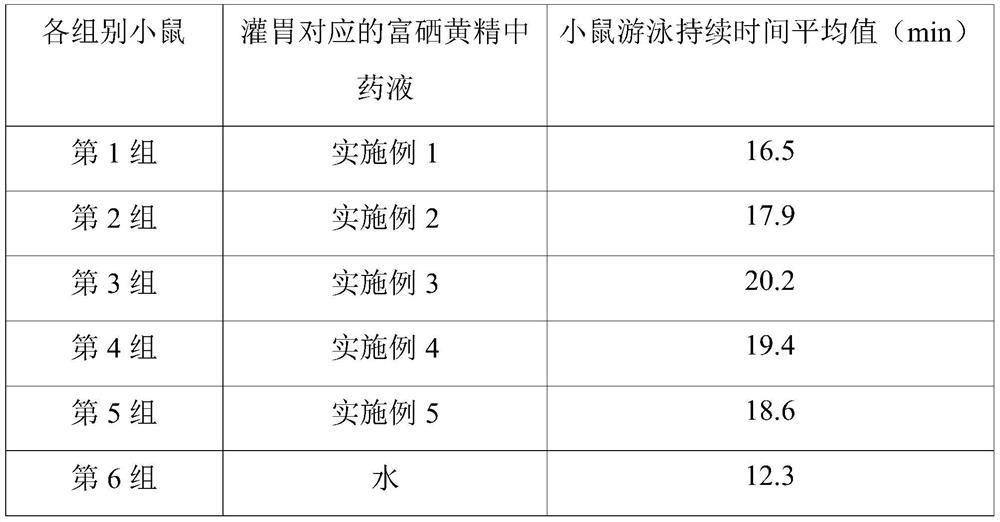

Examples

Embodiment 1

[0053] A processing technology of selenium-enriched Polygonatum medicinal material, comprising the steps of:

[0054] The first steaming and the first drying: The first step is to remove fibrous roots, soil and other sundries and then rinse. The second step is to manually divide into sections. When dividing into sections, try to divide as little as possible. The purpose of reducing incisions is to minimize the loss of medicinal ingredients during the steaming process. Selenium-enriched Polygonatum was washed and sectioned, placed in a bamboo sieve, and weighed after the surface was air-dried. The data was 11kg, and a record was made. The third step is to clean the wooden steamer and pot, put in an appropriate amount of water (the water level is about 6 cm lower than the bottom of the steaming sieve), put the raw selenium-enriched Polygonatum into the steamer from large to small, put the selenium-enriched Polygonatum in the steamer, and then use wet cotton yarn Cover the lid o...

Embodiment 2

[0056] The processing technology of selenium-enriched Polygonatum medicinal material comprises the following steps:

[0057] First, remove the fibrous roots, soil and other debris from the fresh selenium-enriched Polygonatum, rinse it, and then divide it into sections

[0058] Step 1. Put fresh selenium-enriched Polygonatum in a wooden steaming utensil for the first steaming, take river sand, fresh selenium-enriched Polygonatum and black beans and steam together, the mass ratio of river sand to fresh selenium-enriched Polygonatum is 0.5:10, After steaming, the river sand is also separated from the fresh selenium-enriched Polygonatum, the mass ratio of black soybeans and fresh selenium-enriched Polygonatum is 1:10, the particle size of the river sand is 0.5mm, and the first steaming is carried out at a temperature of 115°C. Steam under the seal for 15 minutes;

[0059] Step 2. Perform the first drying on the selenium-enriched Polygonatum after the first steaming. The first dry...

Embodiment 3

[0064] The processing technology of selenium-enriched Polygonatum medicinal material comprises the following steps:

[0065] Firstly, the fresh selenium-enriched Polygonatum is rinsed after removing fibrous roots, soil and other sundries, and then segmented.

[0066] Fifteen days before the expected picking date of Rhizoma Polygonatum, spray a concentration of selenium-enriched foliar fertilizer on the leaves of Polygonatum plant once a day, and spray continuously for 5 times; the selenium-enriched foliar fertilizer can be selected from commercially available ones.

[0067] And after a week without spraying foliar fertilizer, pick them again.

[0068] Step 1. Put fresh selenium-enriched Polygonatum in a wooden steaming utensil for the first steaming, take river sand, fresh selenium-enriched Polygonatum and black beans and steam together, the mass ratio of river sand to fresh selenium-enriched Polygonatum is 1:10, After steaming, the river sand is also separated from the fresh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com