Novel flexible tobacco stem pulping process

A tobacco stem and flexible technology, applied in the field of new flexible tobacco stem pulping process, can solve the problems of low fiber content, heavy impurity gas, low fiber strength, etc., and achieve good slurry drainage, reduction of harmful substances, and suction quality. boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

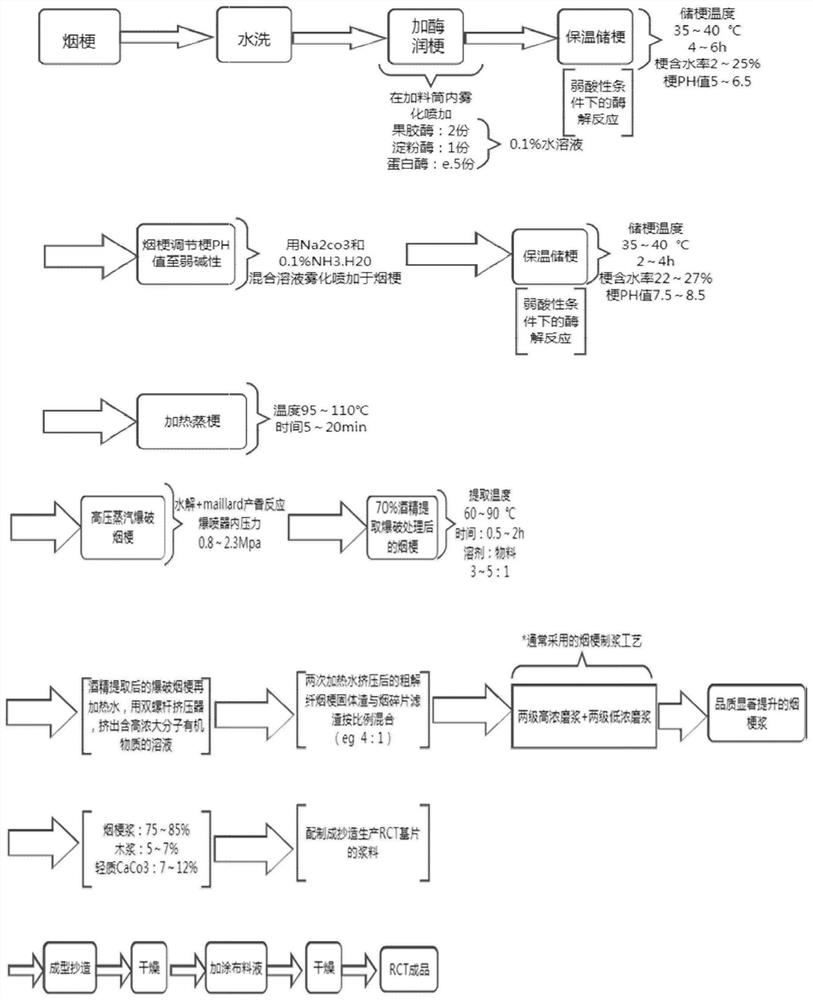

[0060] A New Type of Flexible Tobacco Stem Pulping Process

[0061] (1) prepare the tobacco stems after the leaf-threshing process;

[0062] (2) Enzymatic hydrolysis treatment of tobacco stems under weak acid conditions

[0063] a. The tobacco stems in the raw material are washed with water by a stem washing machine, heated and steamed, cooled to below 40°C, sprayed with 0.1% mixed enzyme aqueous solution, under the condition of weak acidity of the tobacco stem itself (PH5.0-6.5) , carry out enzymatic hydrolysis treatment to tobacco stem, the proportioning of three kinds of commercial enzymes is: pectinase: amylase: protease=3:2:0.5, and the addition amount of enzyme is 0.01% (according to tobacco stem weight);

[0064] b. Thermal insulation storage: the temperature of the storage cabinet is 36±2°C, the storage time is 4 hours, and the moisture content of the tobacco stem is 28-30%;

[0065] (3) Under weakly alkaline conditions, enzymatic hydrolysis of tobacco stems is carri...

Embodiment 2

[0086] A New Type of Flexible Tobacco Stem Pulping Process

[0087] (1) prepare the tobacco stems after the leaf-threshing process;

[0088] (2) Enzymatic treatment of tobacco stems under weak acid conditions: a. The tobacco stems in the raw material are washed with water by a stem washing machine, heated and steamed, cooled to below 40°C, and sprayed with 0.1 % mixed enzyme aqueous solution, under weak acidic conditions for enzymolysis treatment. The proportioning of mixed enzyme is, pectinase: amylase: protease=4:2:1, and the addition amount of enzyme is 0.015% (according to tobacco stem weight);

[0089] b. Thermal insulation storage: the temperature of the storage cabinet is 38±2°C, the storage time is 2 hours, and the moisture content of the tobacco stem is 29-31%;

[0090] (3) Enzymatic hydrolysis treatment of tobacco stems under weakly alkaline conditions:

[0091] a. adjust the pH to weakly alkaline, the tobacco stems processed in step (2) are mixed with a mass conc...

Embodiment 3

[0109] (1) prepare the tobacco stems after the leaf-threshing process;

[0110] (2) Enzymatic treatment of tobacco stems under weak acid conditions: a. The tobacco stems in the raw material are washed with water by a stem washing machine, heated and steamed, cooled to below 40°C, and sprayed with 0.1 % mixed enzyme aqueous solution, under weak acidic conditions for enzymolysis treatment. The proportioning of mixed enzyme is, pectinase: amylase: protease=5:3:0.5, the addition amount of enzyme is 0.020% (by tobacco stem weight);

[0111] b. Thermal insulation storage: the temperature of the storage cabinet is 39±2°C, the storage time is 6 hours, and the moisture content of the tobacco stem is 30-32%;

[0112] (3) Under weakly alkaline conditions, enzymolysis treatment of tobacco stems: a. adjust the pH to weakly alkaline, and use the tobacco stems processed in step (2) with a mass concentration of 10% Na2CO3 solution and saturated NH3.H2O at a ratio of 1: The mass ratio of 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com