Biological corrosion and wear test method and device capable of monitoring on line

A wear test and bio-corrosion technology, which is applied to measuring devices, testing wear resistance, weather resistance/light resistance/corrosion resistance, etc., can solve the problems of large error in test results, inability to realize simultaneous detection of corrosion and wear, and complicated operation. Achieve the effects of small error, accurate and reliable test results, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

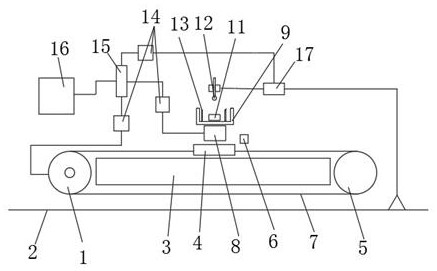

[0035] A biocorrosion wear test method capable of on-line monitoring, comprising the steps of:

[0036] 1) The non-abrasive test surface of the metal sample is evenly pasted and fixed with conductive glue;

[0037] 2) Put the sample with the fixed wires facing down into the cylindrical mold vertically, and use epoxy resin for cold mounting. The time for cold mounting with epoxy resin is 15 minutes, and the diameter of the sample to be mounted is 10 mm. The mounted sample is cleaned with alcohol;

[0038] 3) Clean the inlaid sample, fix the processed sample in the corrosion tank of the bio-corrosion wear test device that can be monitored online, and at the same time, fix the saturated calomel electrode and platinum electrode in the corrosion tank, and carry out Wire connection between electrode and electrochemical workstation;

[0039] 4) Pour a certain amount of corrosive liquid into the corrosion and wear test tank, use a circulating pump to export the corrosive liquid, and...

Embodiment 2

[0043] A biocorrosion wear test method capable of on-line monitoring, comprising the steps of:

[0044] 1) The non-abrasive test surface of the metal sample is evenly pasted and fixed with conductive glue;

[0045] 2) Put the sample with the fixed wires facing down into the cylindrical mold vertically, and use epoxy resin for cold mounting. The time for cold mounting with epoxy resin is 20 minutes, and the diameter of the sample to be mounted is 20 mm. The mounted sample is cleaned with alcohol;

[0046]3) Clean the inlaid sample, fix the processed sample in the corrosion tank of the bio-corrosion wear test device that can be monitored online, and at the same time, fix the saturated calomel electrode and platinum electrode in the corrosion tank, and carry out Wire connection between electrode and electrochemical workstation;

[0047] 4) Pour a certain amount of corrosive liquid into the corrosion and wear test tank, use a circulating pump to export the corrosive liquid, and ...

Embodiment 3

[0051] A biocorrosion wear test method capable of on-line monitoring, comprising the steps of:

[0052] 1) The non-abrasive test surface of the metal sample is evenly pasted and fixed with conductive glue;

[0053] 2) Place the sample with fixed wires facing down into the cylindrical mold vertically, and use epoxy resin for cold mounting. The time for cold mounting with epoxy resin is 30 minutes, and the diameter of the sample to be mounted is 35 mm. The mounted sample is cleaned with alcohol;

[0054] 3) Clean the inlaid sample, fix the processed sample in the corrosion tank of the bio-corrosion wear test device that can be monitored online, and at the same time, fix the saturated calomel electrode and platinum electrode in the corrosion tank, and carry out Wire connection between electrode and electrochemical workstation;

[0055] 4) Pour a certain amount of corrosive liquid into the corrosion and wear test tank, use a circulating pump to export the corrosive liquid, and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com