Preparation method of aluminum adsorbent particles for liquid lithium resource extraction

An adsorbent and particle technology, which is applied in the field of preparation of aluminum-based adsorbent particles, can solve the problems of poor water permeability of adsorbent particles and slow adsorption process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

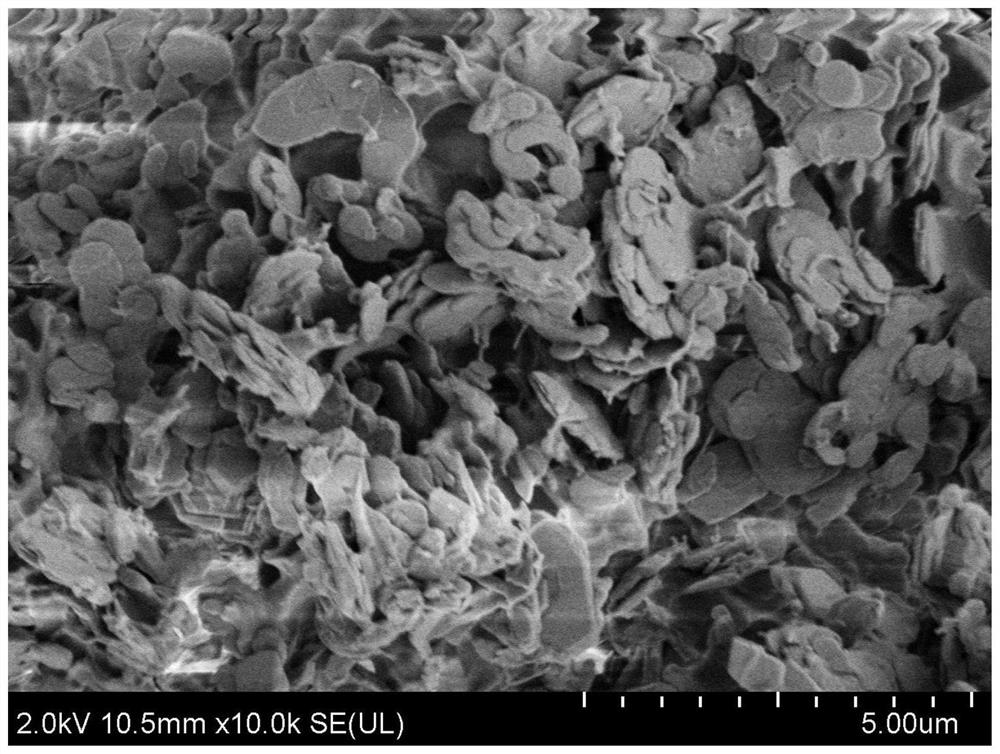

Image

Examples

Embodiment 1

[0074] An aluminum-based adsorbent particle for extraction of liquid lithium resources is carried out in the following manner:

[0075] In the first step, the lithium aluminum hydrotalcite adsorbent is dried at 80°C, and crushed by a high-speed pulverizer to a particle size of 800-1000 mesh to obtain aluminum-based adsorbent powder.

[0076] Step 2, dissolving polyvinyl alcohol with an alcoholysis degree of 85% in water to prepare a 10 wt% polyvinyl alcohol aqueous solution.

[0077] Step 3: Mix polyvinyl alcohol aqueous solution and aluminum-based adsorbent powder at a mass ratio of 5:1, and mix evenly with a three-roll mill.

[0078] Step 4: Add a certain amount of first crosslinking agent aqueous solution to the mixture obtained in step 3, wherein the mass ratio of the mixture to the first crosslinking agent solution is 1:2, and the composition of the first crosslinking agent aqueous solution is 3wt% boric acid, 1wt% borax, 1wt% aluminum chloride, 1wt% calcium chloride, afte...

Embodiment 2

[0085] An aluminum-based adsorbent particle for extraction of liquid lithium resources is carried out in the following manner:

[0086] Step 1, drying the lithium aluminum hydrotalcite adsorbent at 80°C, and crushing it to a particle size of 800-1000 mesh by a high-speed pulverizer to obtain aluminum-based adsorbent powder;

[0087] Step 2, dissolving polyvinyl alcohol with a degree of alcoholysis of 85% in water to prepare a 10wt% solution

[0088] Step 3, dissolving polyacrylic acid with an average molecular weight of 1.25 million in water to prepare a solution with a concentration of 2 wt%.

[0089] Step 4: Mix the polymer aqueous solutions prepared in Step 2 and Step 3 at a mass ratio of 10:1, and use a high-viscosity stirring paddle to mix evenly to obtain a high-viscosity polymer mixed solution. Two types of polymers of the first type can be added, and the second type and the third type can be omitted.

[0090] Step 5. Add the aluminum-based adsorbent powder in step 1 ...

Embodiment 3

[0096] An aluminum-based adsorbent particle for extraction of liquid lithium resources is carried out in the following manner:

[0097] Step 1, drying the lithium aluminum hydrotalcite adsorbent at 80°C, and crushing it to a particle size of 800-1000 mesh by a high-speed pulverizer to obtain aluminum-based adsorbent powder;

[0098] Step 2, dissolving polyvinyl alcohol with a degree of alcoholysis of 85% in water to prepare an 8wt% solution

[0099] Step 3, dissolving sodium polyacrylate with an average molecular weight of 1.25 million in water to prepare a solution with a concentration of 2 wt%.

[0100] Step 4, dissolving sodium alginate in water to prepare a 3wt% solution

[0101] Step 5: Mix the polymer aqueous solution prepared in Step 2, Step 3, and Step 4 in a mass ratio of 10:1:1, and use a high-viscosity stirring paddle to mix evenly to obtain a high-viscosity polymer mixed solution.

[0102] Step 6: Add the adsorbent powder in step 1 to the high-viscosity polymer m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com