Mixed workshop production scheduling method containing multi-path finite continuous output inventory

A production scheduling, hybrid workshop technology, applied in data processing applications, forecasting, instruments, etc., to achieve the effect of increasing space, increasing the proportion of machine production time, and reducing the lower bound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0117] A mixed workshop production scheduling method with multi-path limited continuous output inventory proposed by the present invention will be described in detail below in conjunction with embodiments.

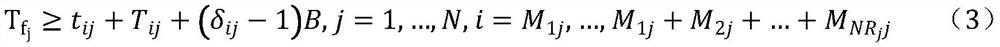

[0118] The invention aims at the workshop production scheduling problem with multi-path limited continuous output inventory, and the performance index is selected as the total delay. It is assumed that all workpieces have multiple processing paths, and each processing path specifies that the workpiece is processed by several different machines in a set order. A machine can only process one workpiece at a time, and the process cannot be interrupted. Each job has a processing time on each machine and an overall lead time. A warehouse is configured behind each machine, with continuous and limited capacity. Then the goal of the shop floor production scheduling model with multi-path finite continuous output inventory is to find the optimal processing path and processing seque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com