Torque sensor interface circuit for EPS system

A technology of torque sensor and interface circuit, applied in the field of torque sensor interface circuit, can solve problems such as safety accidents, increase the computing power of single-chip microcomputer, and poor driving experience, and achieve the effect of improving response speed, solving real-time problems, and expanding measurement range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

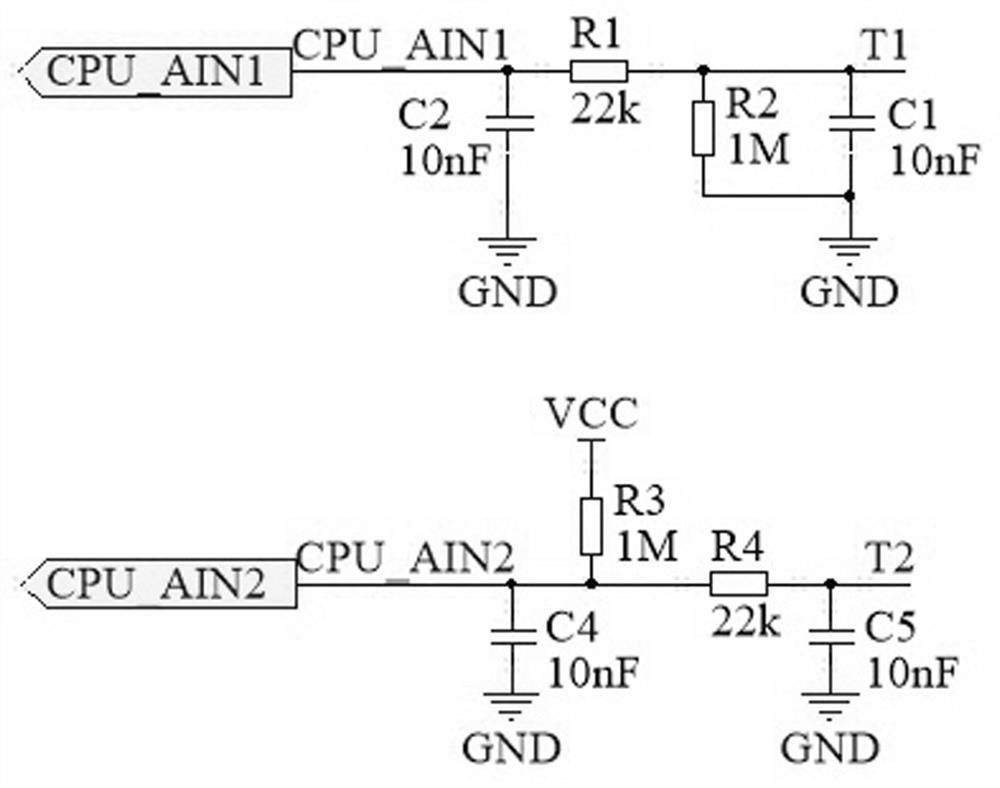

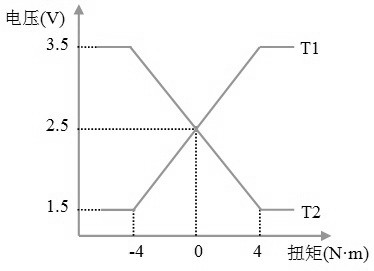

[0022] A torque sensor interface circuit for EPS system, used for leading compensation of torque signal, such as Figure 4 As shown, it includes: a first interface circuit for collecting T1 signals, a second interface circuit for collecting T2 signals, and a lead compensation circuit for collecting PD signals.

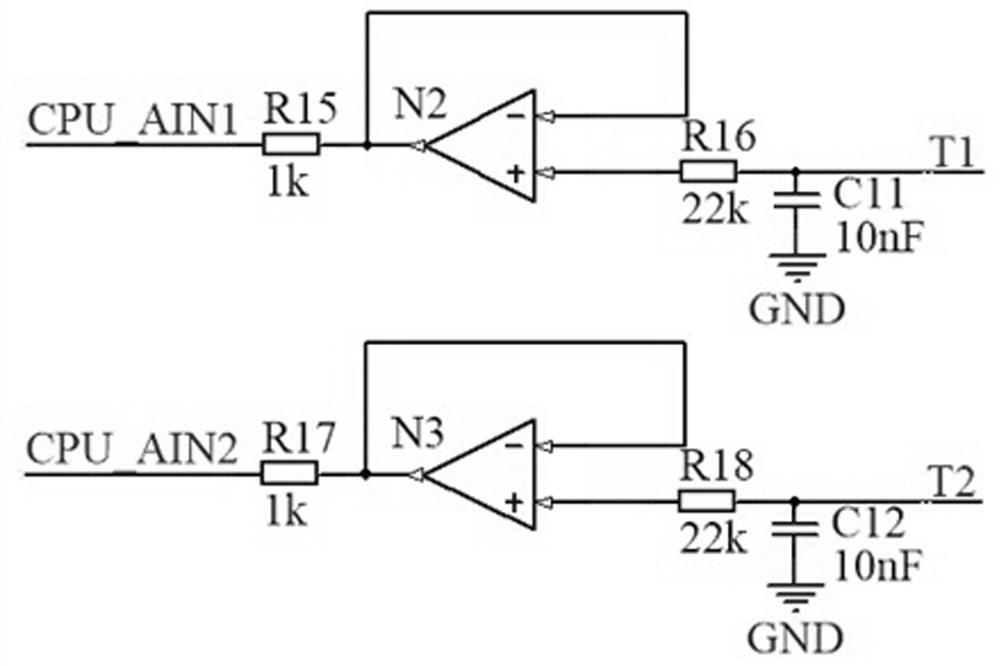

[0023] Specifically, the first interface circuit is connected to the lead compensation circuit, and the lead compensation circuit includes a differential amplifier circuit. The differential amplifier circuit is composed of an operational amplifier N1, a resistor R8, a resistor R5, and a resistor R6. R6 is connected in series to the inverting input terminal of the operational amplifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com