Covalent organic framework material as well as preparation method and application thereof

A covalent organic framework and organic solvent technology, applied in chemical instruments and methods, other chemical processes, iodine/hydrogen iodide, etc., can solve the problem of long iodine adsorption equilibrium time, achieve fast adsorption speed, strong adsorption capacity, The effect of channel order

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: The preparation method of the covalent organic framework material of this embodiment is carried out according to the following steps:

[0030] 1. Weigh 0.14g of 2-(4-aminophenyl)-1H-phenanthrene[9,10-d]imidazole-6,9-diamine and 0.21g of isophthalaldehyde respectively, and add them to the schlenk tube, Then add 1.0mL n-butanol and 0.05mL glacial acetic acid, mix well;

[0031] 2. The schlenk tube is evacuated and nitrogen-filled cycle operation, so that the nitrogen environment in the schlenk tube is maintained;

[0032] 3. Heat the schlenk tube to 115°C and react for 5 days;

[0033] 4. Cool down to room temperature after the reaction, filter with suction, wash the filter cake repeatedly with methanol, and dry in vacuum to obtain a covalent organic framework material with a yield of 78%.

[0034] In this embodiment, the schlenk tube is Shrek

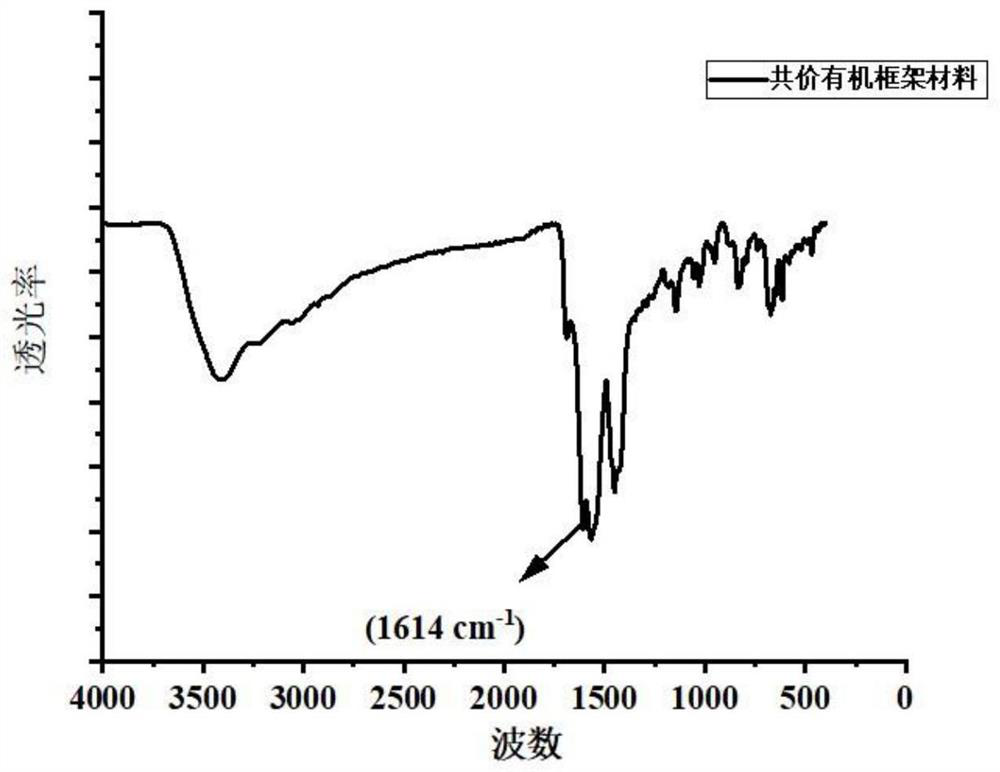

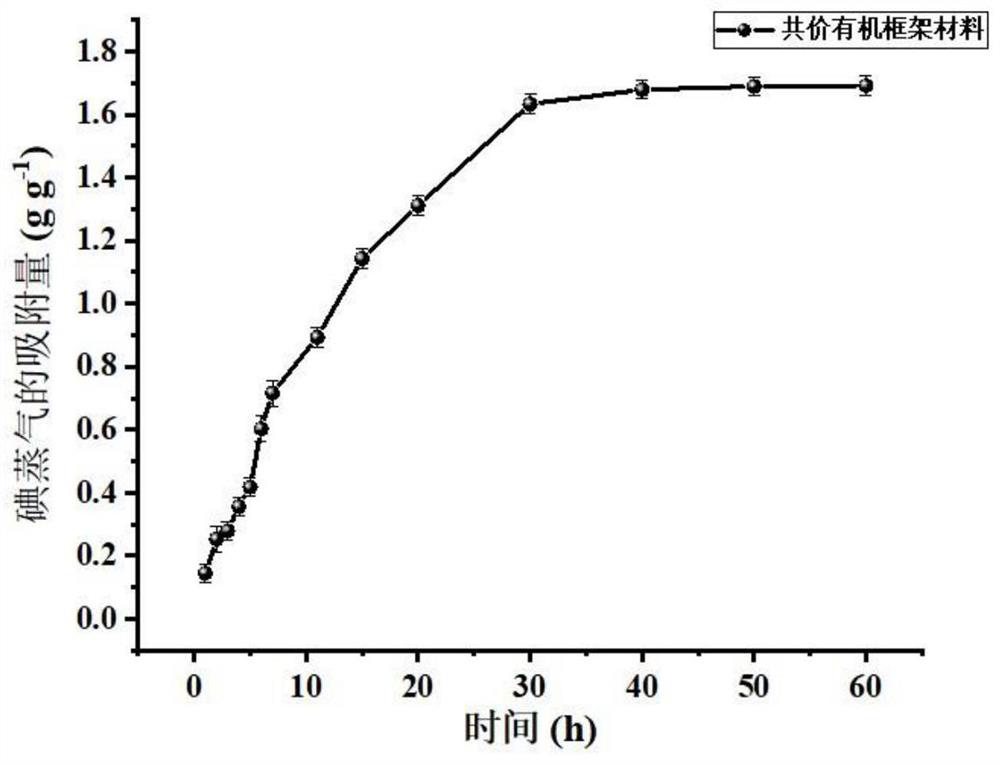

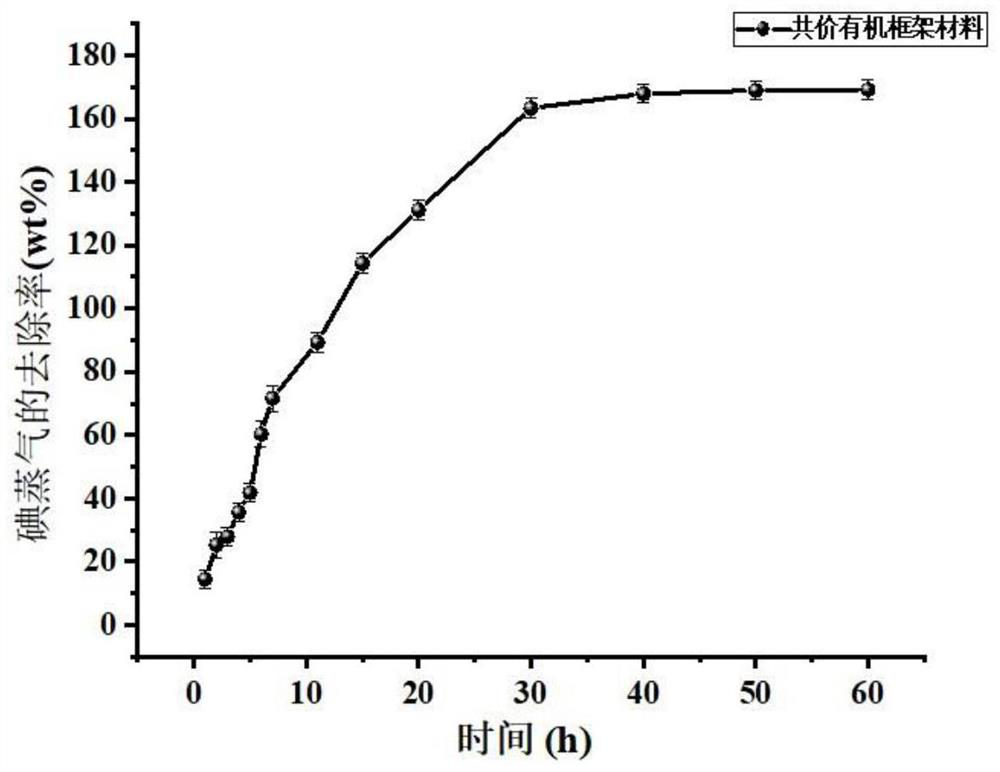

[0035] Structural characterization of the covalent organic framework material in Example 1 was carried out by F...

Embodiment 2

[0058] Embodiment 2: The preparation method of the covalent organic framework material of this embodiment is carried out according to the following steps:

[0059] 1. Weigh 0.14g of 2-(4-aminophenyl)-1H-phenanthrene[9,10-d]imidazole-6,9-diamine and 0.17g of m-phthalaldehyde respectively, and add them to the schlenk tube, Then add 1.0mL N,N-dimethylformamide and 0.05mL concentrated hydrochloric acid with a mass fraction of 37%, and mix well;

[0060] 2. The schlenk tube is evacuated and nitrogen-filled cycle operation, so that the nitrogen environment in the schlenk tube is maintained;

[0061] 3. Heat the schlenk tube to 150°C and react for 3 days;

[0062] 4. Cool down to room temperature after the reaction, filter with suction, wash the filter cake repeatedly with ethyl acetate, and dry in vacuum to obtain a covalent organic framework material, with a yield of 69%.

Embodiment 3

[0063] Embodiment 3: The preparation method of the covalent organic framework material of this embodiment is carried out according to the following steps:

[0064] 1. Weigh 0.14g of 2-(4-aminophenyl)-1H-phenanthrene[9,10-d]imidazole-6,9-diamine and 0.05g of m-phthalaldehyde respectively, and add them to the schlenk tube, Then add 0.5mL N,N-dimethylformamide, 0.5mL dioxane and 0.05mL concentrated sulfuric acid with a mass fraction of 98%, and mix well;

[0065] 2. The schlenk tube is evacuated and nitrogen-filled cycle operation, so that the nitrogen environment in the schlenk tube is maintained;

[0066] 3. Heat the schlenk tube to 130°C and react for 5 days;

[0067] 4. Cool down to room temperature after the reaction, filter with suction, wash the filter cake repeatedly with ethanol, and dry in vacuum to obtain a covalent organic framework material with a yield of 75%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com