Packaging bag sealing device

A sealing device, packaging bag technology, applied in packaging sealing/fastening, packaging, transportation packaging, etc., can solve problems such as reducing equipment service life, component position deviation, processing quality impact, etc., to improve quality and speed, friction The effect of reducing force and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

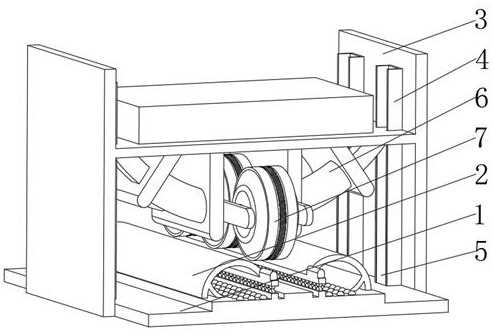

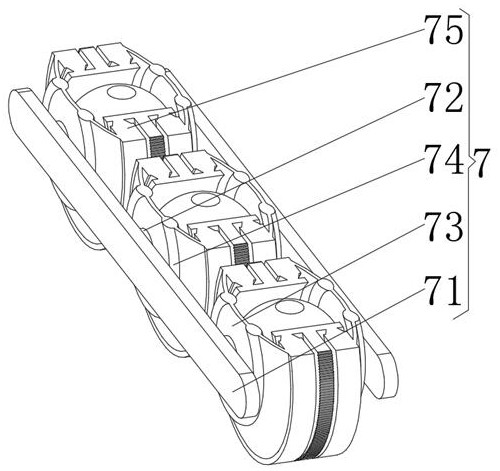

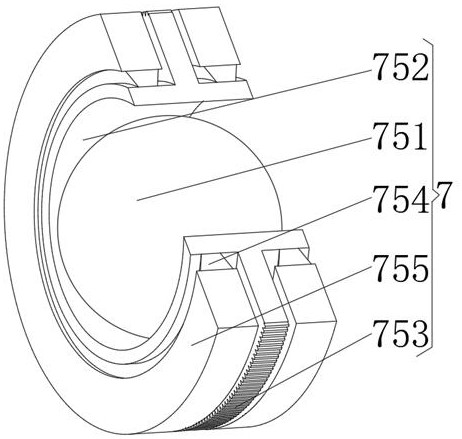

[0044] see Figure 1-5 , the present invention provides a technical solution: a packaging bag sealing device, specifically comprising:

[0045] Base 1, the base 1 has a square seat plate, and a conveying device 2 installed in the middle of the top of the square seat plate, and a support frame plate 3 installed in the middle of the outer walls on both sides of the square seat plate, and installed on the support frame plate 3 close to The limiting concave plate 4 on one side of the conveying device 2, and the lifting adjustment column 5 installed at the bottom of the inner cavity of the limiting concave plate 4, and the temperature control device 6 installed on the top of the lifting adjusting column 5, and installed on the temperature control device 6 The sealing device 7 in the middle position restricts the running track of the equipment components through the setting of the limiting concave plate 4, avoids misalignment and offset during the movement, and protects the equipmen...

Embodiment 2

[0057] see Figure 1-5 On the basis of Embodiment 1, the present invention provides a technical solution: a method for using a packaging bag sealing device, comprising the following steps,

[0058] Step 1: start the driver 28, so that the top conveying wheel 24 is powered to rotate and convey, and use the gravity of the top conveying wheel 24 to attach to the bottom conveying wheel 23;

[0059] Step 2: start the heating coil 66 in the temperature control device 6, so that the heating coil 66 heats the curved curved rod 65;

[0060] Step 3: Start the lifting and adjusting column 5, so that the bearing plate 62 of the temperature control device 6 starts to descend, and drives the positioning partition 63 to move downward until the installation ring plate 755 in the sealing wheel 75 contacts the sealing bottom plate 22 in the conveying device 2 ;

[0061] Step 4: Put the mouth of the packaging bag between the top conveying wheel 24 and the bottom conveying wheel 23, and use the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com