Metal part induction heating coil winding device

A technology for induction heating coils and metal parts, applied in the field of induction heating coil winding devices for metal parts, can solve problems such as uneven temperature, insufficient heating temperature, and different sizes of coils of the same specification, so as to improve product quality and ensure stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

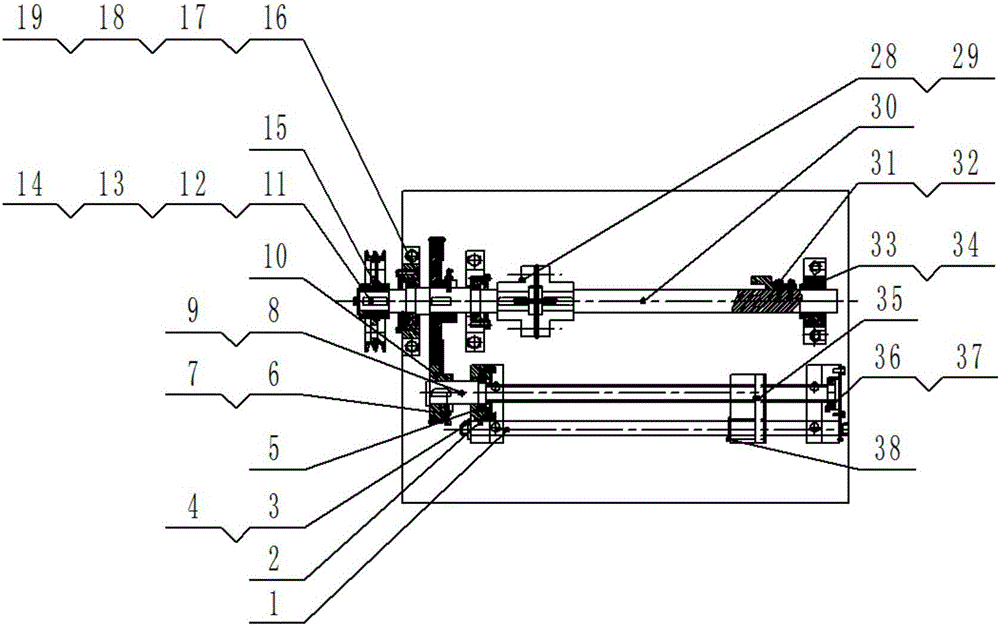

[0026] A metal parts induction heating coil winding device, such as figure 1 and figure 2 As shown, it includes: fixed shaft 1, first bearing seat 2, flat washer 3, thread 4, bearing 5, bolt 6, nut 7, screw shaft 8, flat key 9, driven gear 10, main transmission shaft 11, Flat key 12, flat key 13, bolt 14, driven pulley 15, second bearing seat 16, bearing 17, gland 18, bolt 19, pendulum reducer 20, main pulley 21, V-belt 22, flat key 23, Drive gear 24, hexagon socket bolt 25, nut 26, machine tool table 27, coupling 28, flat key 29, winding system winding mandrel 30, fixed plate 31, bolt 32, third bearing seat 33, sliding bearing 34, slide rail 35, bearing seat 36, bearing 37, sliding bearing 38.

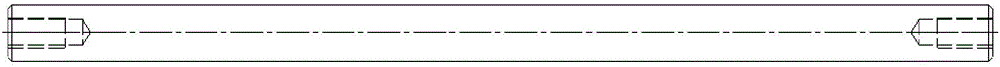

[0027] In machine tool table 27 (shape and structure such as Figure 13 Shown) below is provided with pendulum reducer 20 and primary pulley 21 (shape and structure such as Figure 11 Shown), primary pulley 21 and driven pulley 15 (shape and structure such as Figure 8 shown) tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com