Prefabricated hollow tube device for hollow floor slab

A technology of hollow floor slab and hollow tube

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

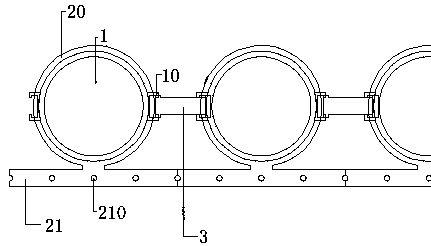

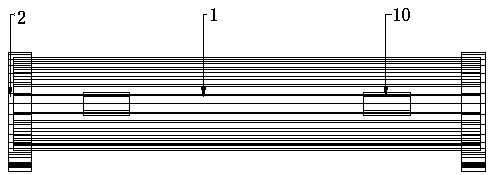

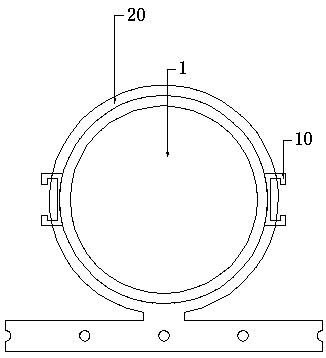

[0030] Attached below Figure 1-7 The present invention is described in further detail: as Figure 1-2 As shown, a prefabricated hollow tube device for hollow floor, including hollow tube 1 and pipe sleeve 2; The connecting groove 10 connects the adjacent hollow pipes 1 through the connecting device 3 matched with the connecting groove; it also includes a sleeve 2 installed at the end of the hollow pipe for sealing the openings at both ends of the hollow pipe 1 .

[0031] Such as figure 2 , 5 As shown, the pipe sleeve 2 includes a pipe cover 20 and a stopper 21; the pipe cover 20 is sleeved on the end of the hollow pipe 1, and the stopper 21 is arranged at the lower part of the pipe cover 20, and is used for restricting the center when pouring concrete. Floating of the empty tube; the stopper 21 extends radially and horizontally along the tube cover 20, and is provided with a reserved hole 210 for the steel bar 211 to pass through, and the axial direction of the reserved h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com