Fiber cement board dry hanging structure

A fiber cement board, dry-hanging technology, applied in building construction, covering/lining, construction, etc., can solve the problems of affecting the aesthetics of the finish, the limitation of the width of the board, and the many seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

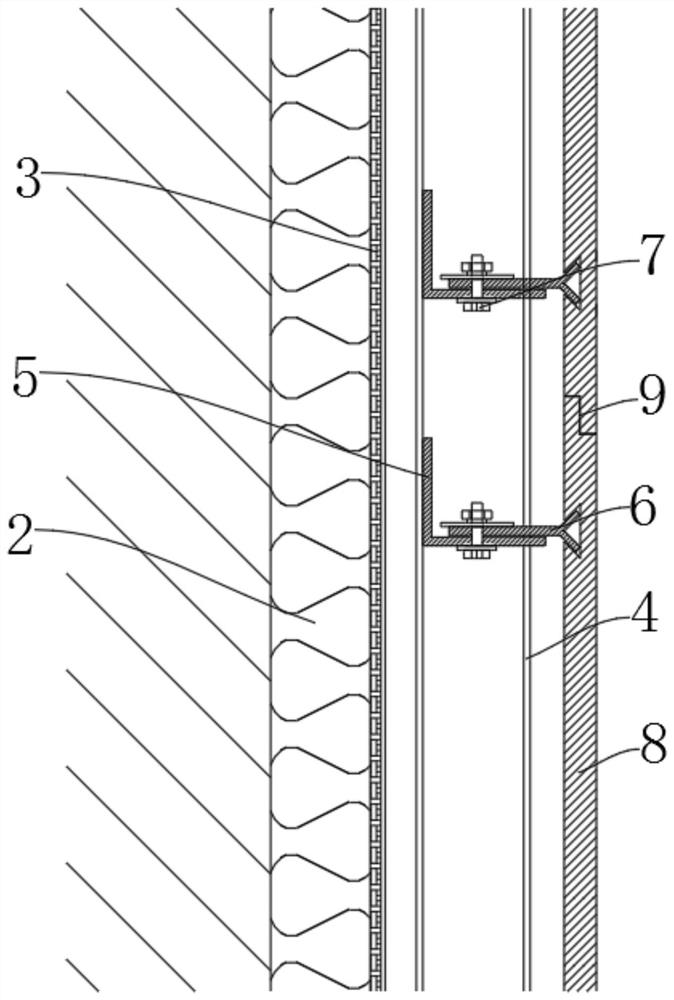

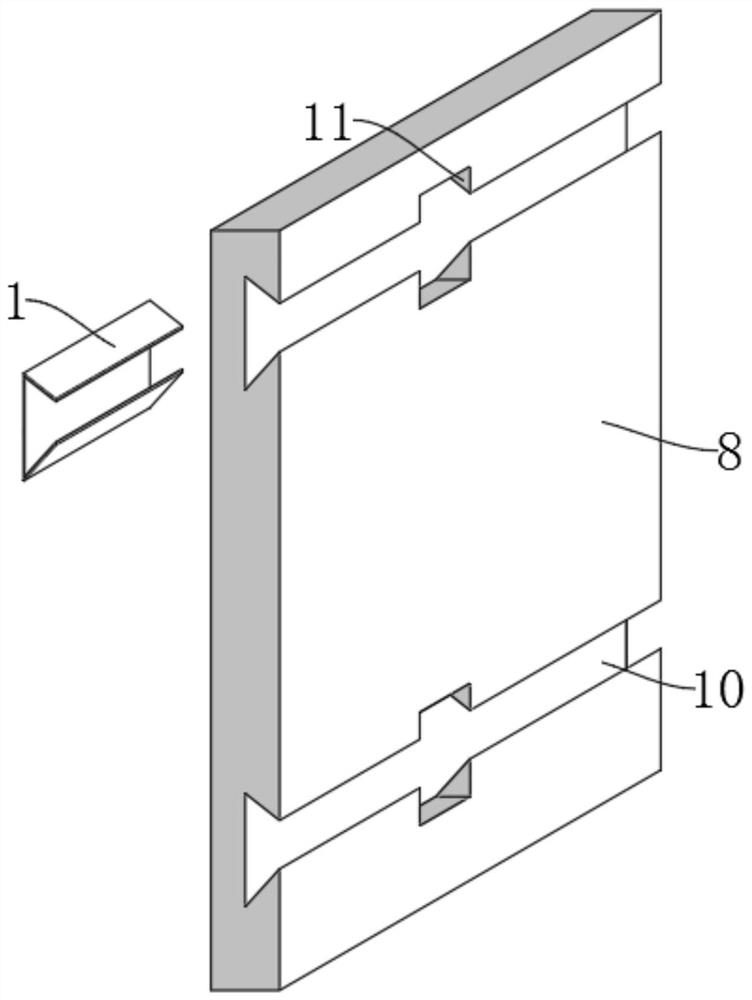

[0030] refer to Figure 1-6 , a fiber cement board dry-hanging structure, including a fiber cement board 8, an inverted trapezoidal groove 10 is opened in the fiber cement board 8, and a dry hanging part 6 is clamped in the inverted trapezoidal groove 10; The matched liner 1 and the dry hanger 6 are connected in the liner 1;

[0031] The inverted trapezoidal groove 10 is provided with a reserved opening 11 for hanging parts. The groove depth of the inverted trapezoidal groove 10 is 6 mm. The fiber cement board 8 is connected with a column 4 through a dry hanging part 6 .

[0032] An inverted trapezoidal groove 10 of a certain depth is milled out on the back side of the fiber cement board 8, and an inverted T-shaped groove can also be selected when the single-point drawing force with a groove depth of 8 mm or more meets the requirements.

[0033] Processing technology and spacing calculation of inverted trapezoidal grooves 10 on the back of fiber cement board 8, reference stan...

Embodiment 2

[0046] refer to Figure 1-6 , a fiber cement board dry-hanging structure, comprising a fiber cement board 8, an inverted trapezoidal groove 10 is opened in the fiber cement board 8, and a dry hanging part 6 is clamped in the inverted trapezoidal groove 10;

[0047] The lining board 1 matched with it is plugged into the inverted trapezoidal groove 10, and the dry hanger 6 is connected in the lining board 1;

[0048] The inverted trapezoidal groove 10 is provided with a reserved opening 11 for hanging parts. The groove depth of the inverted trapezoidal groove 10 is 6 mm. The fiber cement board 8 is connected with a column 4 through a dry hanging part 6 .

[0049] The outer column 4 is fixedly connected with a waterproof and breathable layer 3, and a layer of thermal insulation layer 2 is laid outside the waterproof and breathable layer 3, and the thermal insulation layer 2 is arranged between the waterproof and breathable layer 3 and the body of wall.

[0050]There are two fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com