A kind of assembly and construction method of cool rice warehouse for rice processing

A technology of rice processing and cold rice, which is applied in the direction of assembly machines, metal processing equipment, applications, etc., can solve the problems of shortened service life of cold rice bins, inability to guarantee the quality of rice grains, rust and loose bolts, etc., so as to facilitate assembly and construction and shorten production Cycle, the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

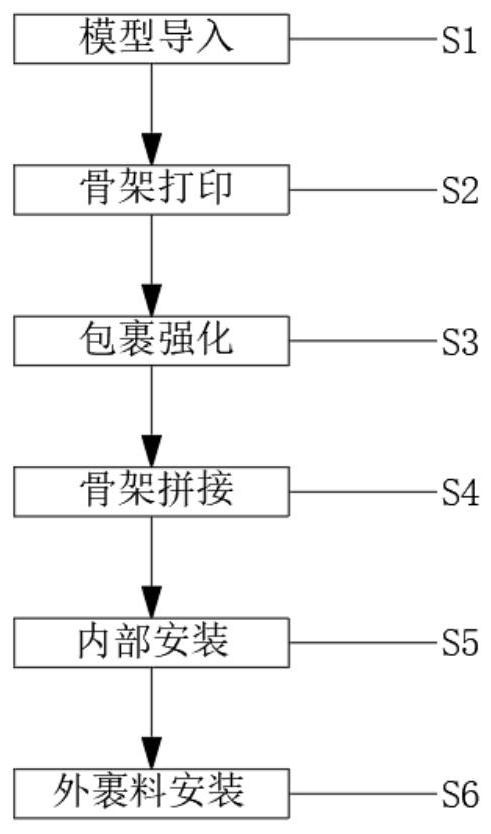

[0033] A method for assembling and building a cold rice warehouse for rice processing, comprising the following steps:

[0034] S1: Model import: Construct the overall model of the cold rice warehouse through software. The cold rice warehouse adopts a spiral building structure inside. Import the cold rice warehouse model into the 3D printing software, disassemble its parts, and put the cold rice warehouse into a 3D printing software. The whole is divided into two parts: the skeleton and the outer wrapping material;

[0035] S2: Skeleton printing: use 3D printing software to print the skeleton part disassembled in step S1. The printed skeleton is a solid round rod with a length of 55cm and a diameter of 3cm. Both sections of the rod are designed with tenon and tenon structures, and cold rice is printed The screw plate inside the warehouse, the splicing surface of the screw plate and the skeleton is square, and the inner side is arc-shaped;

[0036] S3: Wrapping strengthening: ...

Embodiment 2

[0042] A method for assembling and building a cold rice warehouse for rice processing, comprising the following steps:

[0043] S1: Model import: Construct the overall model of the cold rice warehouse through software. The cold rice warehouse adopts a spiral building structure inside. Import the cold rice warehouse model into the 3D printing software, disassemble its parts, and put the cold rice warehouse into a 3D printing software. The whole is divided into two parts: the skeleton and the outer wrapping material;

[0044] S2: Skeleton printing: use 3D printing software to print the skeleton part disassembled in step S1. The printed skeleton is a solid round rod with a length of 58cm and a diameter of 3.6cm. The screw plate inside the rice warehouse, the splicing surface of the screw plate and the skeleton is square, and the inner side is arc-shaped;

[0045] S3: Wrapping strengthening: Wrap the solid round bar printed in step S2 and the periphery of the screw plate with 304...

Embodiment 3

[0051] A method for assembling and building a cold rice warehouse for rice processing, comprising the following steps:

[0052] S1: Model import: Construct the overall model of the cold rice warehouse through software. The cold rice warehouse adopts a spiral building structure inside. Import the cold rice warehouse model into the 3D printing software, disassemble its parts, and put the cold rice warehouse into a 3D printing software. The whole is divided into two parts: the skeleton and the outer wrapping material;

[0053] S2: Skeleton printing: use 3D printing software to print the skeleton part disassembled in step S1. The printed skeleton is a solid round rod with a length of 56cm and a diameter of 3.3cm. The screw plate inside the rice warehouse, the splicing surface of the screw plate and the skeleton is square, and the inner side is arc-shaped;

[0054] S3: Wrapping strengthening: Wrap the solid round bar printed in step S2 and the periphery of the screw plate with 304...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com