Marine inclined ladder welding device

The technology of welding device and inclined ladder is applied in the field of marine inclined ladder welding device, which can solve the problems of limited working range and difficult fixing, and achieve the effect of increasing adsorption and sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

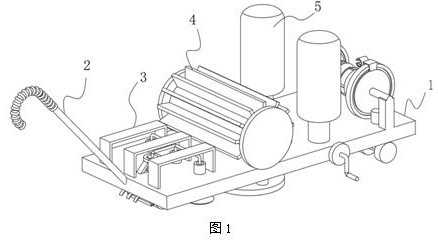

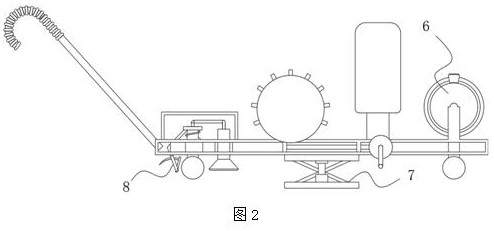

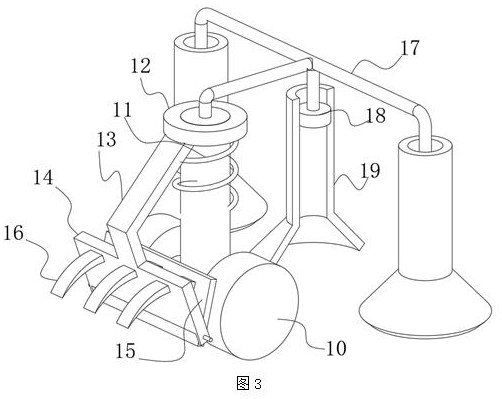

[0026] use Figure 1 - Figure 6 A marine slope welding apparatus according to an embodiment of the present invention is carried out as follows.

[0027] like Figure 1 - Figure 6 As shown, a marine slope welding apparatus according to the present invention includes a bottom plate 1; the outer surface of the left side of the bottom plate 1 is rotatable to connect the traction rod 2, and the right side of the traction rod 2 is provided with a protective frame 3, and the protective frame 3. The lower surface is fixed to the upper surface of the bottom plate 1, and a transformer 4 is provided on the right side of the guard frame 3. The lower surface of the transformer 4 is fixed to the upper surface of the bottom plate 1, and the right side of the transformer 4 is fixedly connected to the gas storage bottle 5, store On the right side of the gas cylinder 5, the winding mechanism 6 is provided, and the outer surface of the winding mechanism 6 is rotatable to the upper surface of the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com