Construction Equipment and Construction Method of Secondary Lining Concrete for Long Longitudinal Slope

A technology of long longitudinal slope and construction method, applied in mining equipment, shaft equipment, shaft lining and other directions, can solve the overall stability of the tunnel with the strength of the secondary lining concrete, the concrete pouring is not compact, and the trolley of the secondary lining trolley slips down. and other problems to achieve the effect of ensuring the pouring quality, preventing the trolley from slipping, and solving the trolley slipping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

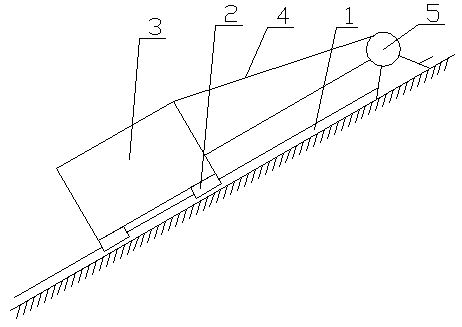

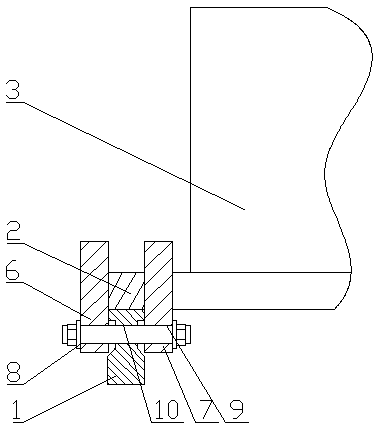

[0031] Such as figure 2 and 3 As shown, a kind of equipment for the construction of the second-lined concrete on a long longitudinal slope, including a steel rail 1, a rail wheel 2, a steel mold trolley 3, a traction rope 4 and a hoist 5, and the steel mold trolley 3 is placed on the steel rail 1 through the rail wheel 2 Move, the hoist 5 pulls the steel mold trolley 3 through the traction rope 4, and the two sides of the rail wheel 2 are respectively provided with an outer wheel body 6 and an inner wheel body 7, wherein the outer wheel body 6 is located on the outside of the rail 1, and the inner wheel body 7 is located on the rail 1 The inner side of the outer wheel body 6 is provided with a first screw hole 8, and the inner wheel body 7 is provided with a second screw hole 9, and the first screw hole 8 and the second screw hole 9 are aligned with each other. On the body of the rail 1 The connecting through holes 10 that can be aligned and communicated with the first screw...

Embodiment 2

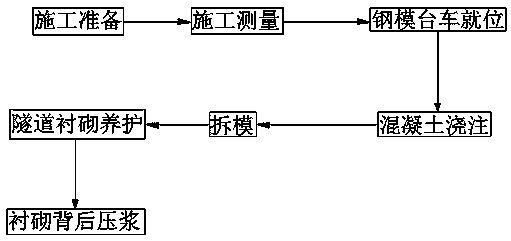

[0033] Such as figure 1 and 2 As shown, the construction method of the second lining concrete for long longitudinal slopes includes the following steps:

[0034] Step 1. Construction preparation: Before the secondary concrete lining, the following work must be carried out,

[0035] (1) Clean up the debris that affects the laying of the waterproof board, such as the bolt head and small pipe head that invaded the design range of the secondary lining during the initial support of the tunnel, and level it with sprayed concrete;

[0036] (2) Install the construction equipment, complete the assembly of the steel formwork trolley 3, check the rigidity of the formwork, the hydraulic system, the flatness of the formwork surface, the handling of formwork joints, and apply the release agent;

[0037] (3) Make a detailed map of the mileage position of the embedded parts and the embedded holes, and process the template of the embedded holes to ensure that the embedded positions are accur...

Embodiment 3

[0049] Such as figure 1 and 2 As shown, the construction method of the second lining concrete for long longitudinal slopes includes the following steps:

[0050] Step 1. Construction preparation: Before the secondary concrete lining, the following work must be carried out,

[0051] (1) Clean up the debris that affects the laying of the waterproof board, such as the bolt head and small pipe head that invaded the design range of the secondary lining during the initial support of the tunnel, and level it with sprayed concrete;

[0052] (2) Install the construction equipment, complete the assembly of the steel formwork trolley 3, check the rigidity of the formwork, the hydraulic system, the flatness of the formwork surface, and the treatment of formwork joints, and apply the release agent;

[0053] (3) Make a detailed map of the mileage position of the embedded parts and the embedded holes, and process the template of the embedded holes to ensure that the embedded positions are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com