Drying device for processing trichosanthes kirilowii maxim seeds

A drying device and the technology of melon seeds are applied in the directions of application, separation of solids from solids by air flow, separation of solids, etc., which can solve the problems of low efficiency and labor consumption, and achieve high drying efficiency, improve quality, Well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

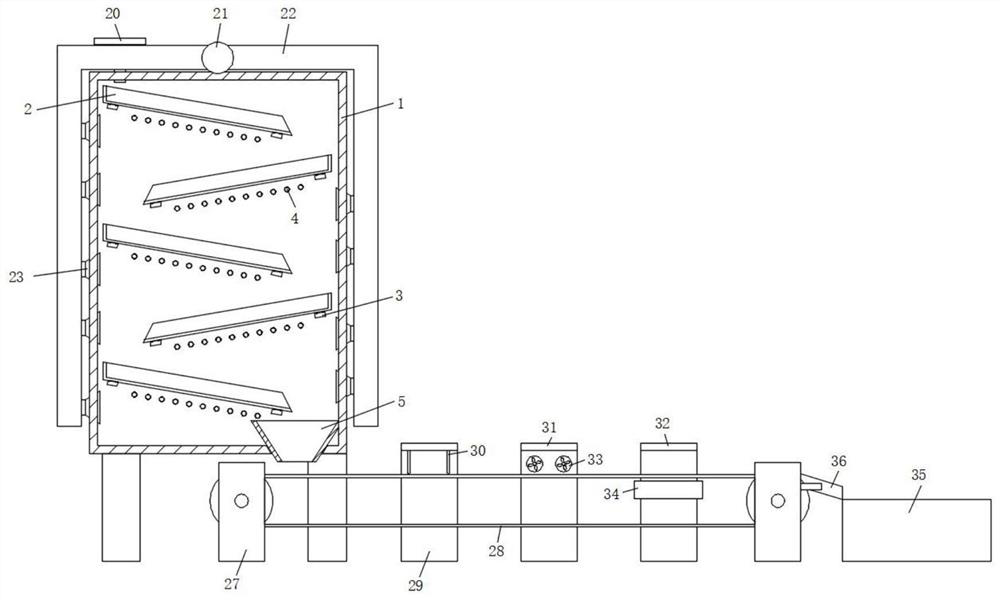

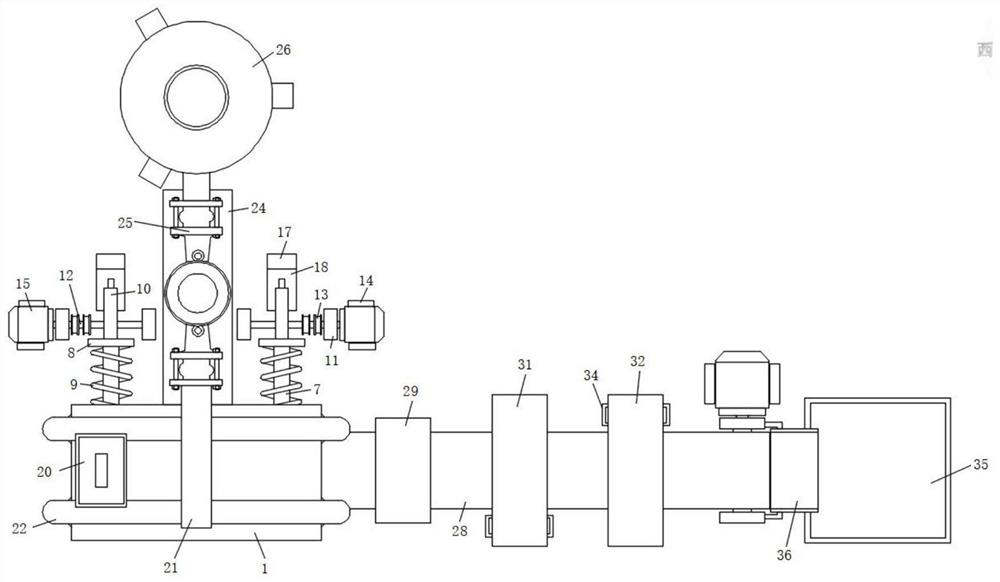

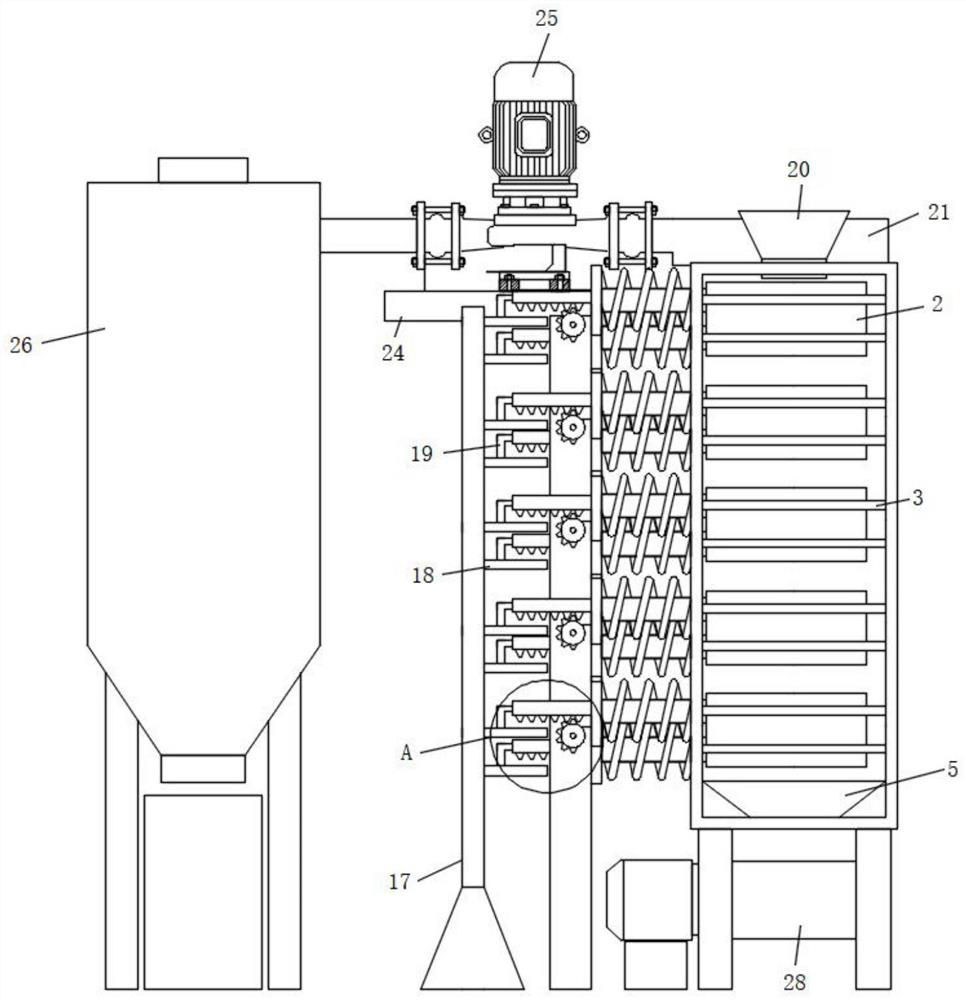

[0029] refer to Figure 1-4, a drying device for processing Trichosanthes seeds, comprising a drying box 1, four corners of the bottom surface of the drying box 1 are fixed with supporting legs, a shaking plate 2 is arranged in the drying box 1, and a shaking plate 2 Both sides of the lower end are provided with support strips 3, the top surface of the support strips 3 is provided with rolling grooves, the bottom surface of the shaking plate 2 is also equipped with balls, the balls are rollingly connected in the rolling grooves, and the lower side of the shaking plate 2 is also provided with a heating tube 4, One side of the bottom surface of the drying box 1 is also connected with a discharge dish 5, and both sides of the rear end surface of the shaking disk 2 are fixed with push rods 7, and the rear end side walls of the push rods 7 are fixed with a limit plate 8, which is close to One end of the drying cabinet 1 is fixed with a return spring 9, and the center position of th...

Embodiment 2

[0031] Such as figure 1 and 2 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the condensing mechanism includes a mounting seat 27, a conveyor belt 28 is mounted on the upper end of the mounting seat 27, and a mounting frame 29 is erected on one side of the middle part of the conveyor belt 28. The inner bottom surface of the mounting frame 29 is Be fixed with dispersing bar 30, the other side of conveyer belt 28 middle parts is set up with installation frame two 31 and installation frame three 32, and installation frame two 31 rear end upper side and installation frame three 32 front end upper side inboards are all equipped with exhaust fan 33, installation frame The front and rear sides of the middle part of the second 31 and the third 32 of the installation frame are fixedly connected with a miscellaneous dish 34, the side of the conveyor belt 28 away from the drying box 1 is also provided with a collection dish 35, and the side of the conveyor b...

Embodiment 3

[0035] Such as figure 1 As shown, the present embodiment is basically the same as Embodiment 2. Preferably, the dispersing rods 30 are provided with a plurality of them and are evenly distributed in two rows on both sides of the inner bottom surface of the mounting frame one 29, and the front and rear side belt surfaces of the conveyor belt 28 are all in line with the installation Frame one 29 inner walls are fitted.

[0036] In this embodiment, multiple dispersing rods 30 are provided, so that the dispersing effect of the Trichosanthes seeds is better, and furthermore, a certain guarantee is provided for the rapid condensation of the Trichosanthes seeds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com