Variable compression ratio engine crankshaft device

A technology of compression ratio and engine, applied in the direction of engine components, machine/engine, crankshaft bearing, etc., can solve the problem that it is impossible to ensure that the compression ratio of the engine is completely consistent at the same time, and achieve the effect of completely consistent compression ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

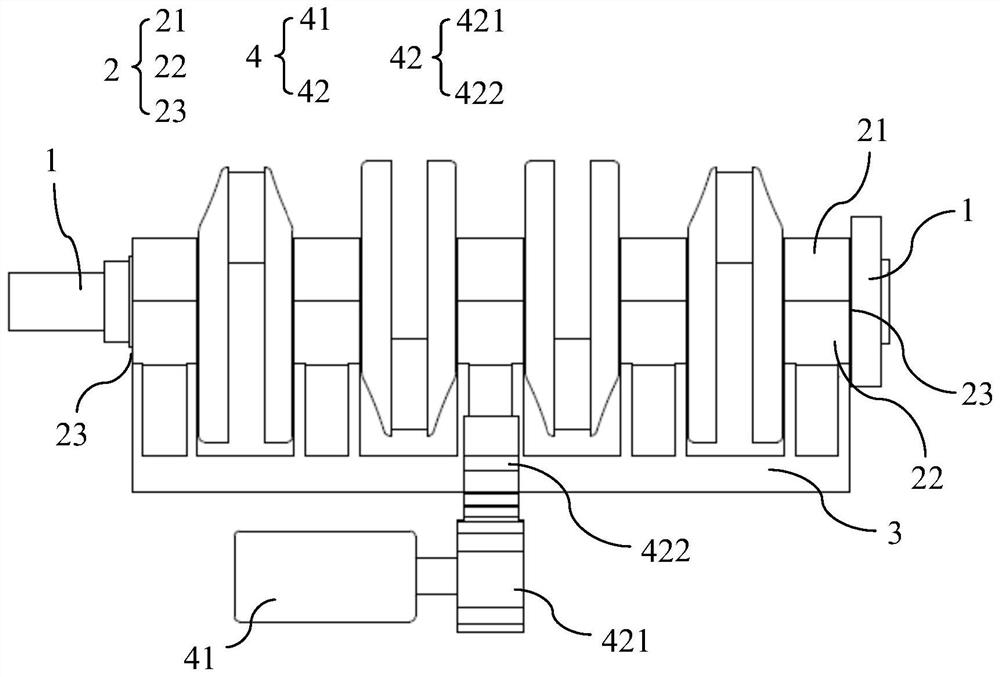

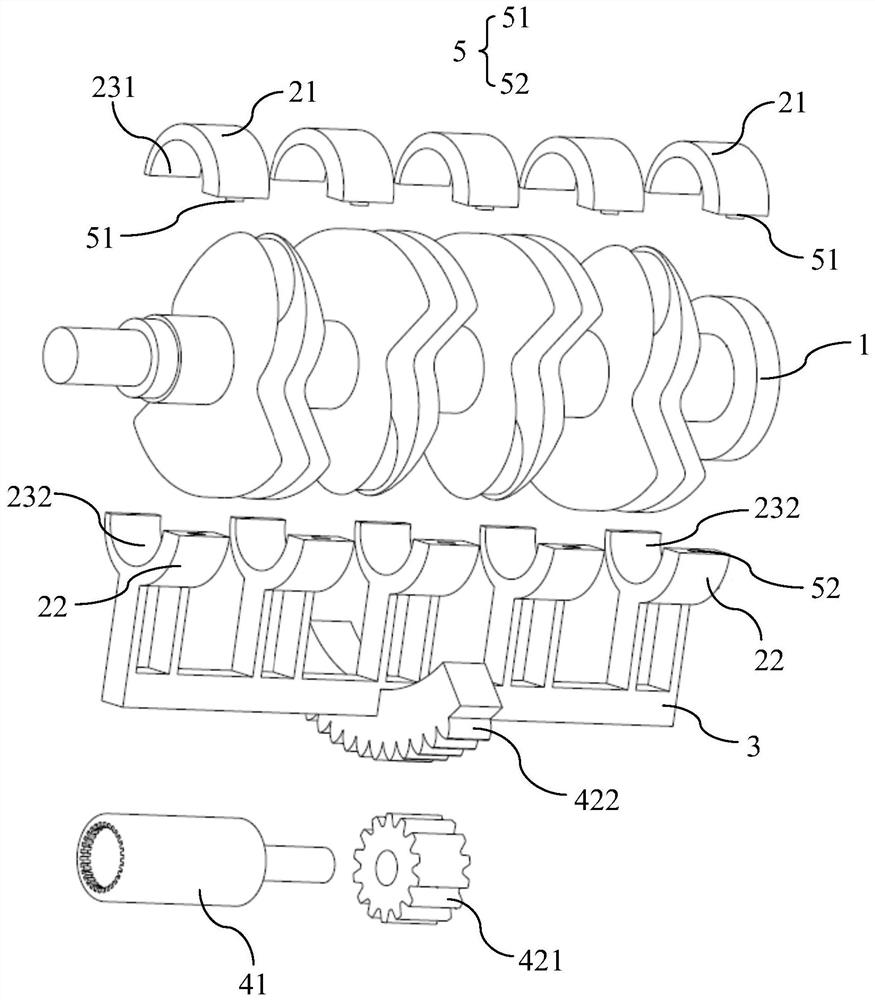

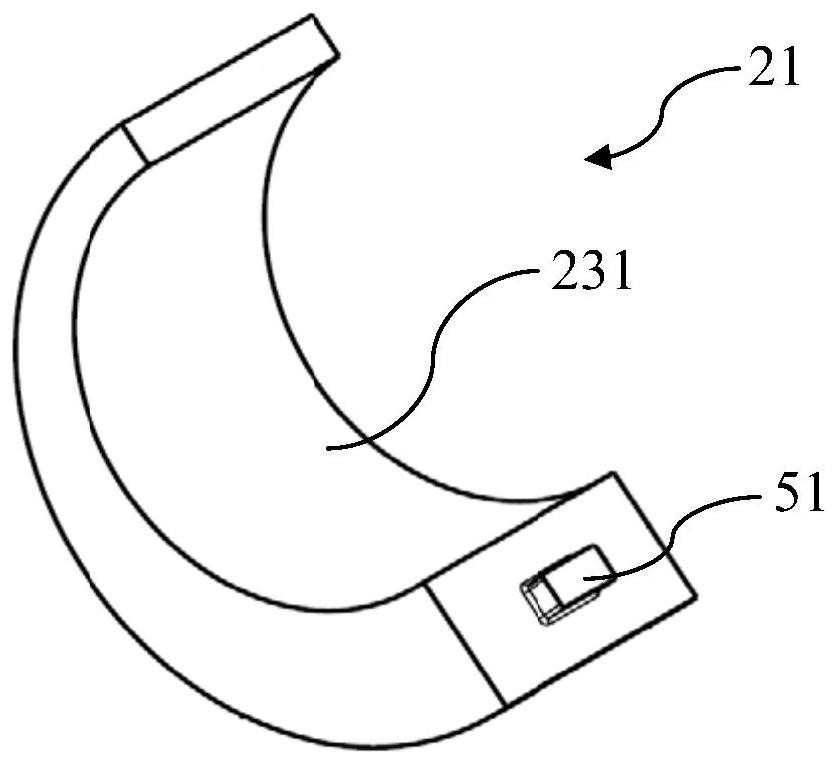

[0029] Further, see figure 1 and figure 2 , as a specific embodiment of the variable compression ratio engine crankshaft device provided by the present invention, the eccentric bushing 2 includes an upper eccentric bushing body 21 and a lower eccentric bushing body 22, and the upper eccentric bushing body 21, The cross-section of the lower eccentric shaft sleeve body 22 is semicircular; the upper eccentric shaft sleeve body 21 is provided with an upper eccentric groove 231, and the lower eccentric shaft sleeve body 22 is provided with a lower eccentric groove 232; the upper eccentric shaft sleeve body 22 is provided with a lower eccentric groove 232; The shaft sleeve body 21 is docked with the lower eccentric shaft sleeve body 22 so that the upper eccentric groove 231 is engaged with the lower eccentric groove 232 to form the eccentric hole 23 . In this way, it is convenient to assemble with the crankshaft 1 , and at the same time, it is more convenient to overhaul the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com