Water-resisting layer strengthening grouting transformation device and method based on staged fracturing

A technology of enhanced grouting and staged fracturing, which is applied in the directions of earthwork drilling, sealing/packing, and mining fluids, etc., to achieve the effects of suppressing disturbance effects, improving grout migration and circulation space, and enhancing mixing and grouting operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Embodiments of the technical solution of this embodiment will be described in detail below in conjunction with the accompanying drawings. The following embodiments are only used to illustrate the technical solution of this embodiment more clearly, so they are only examples, and should not be used to limit the protection scope of this embodiment.

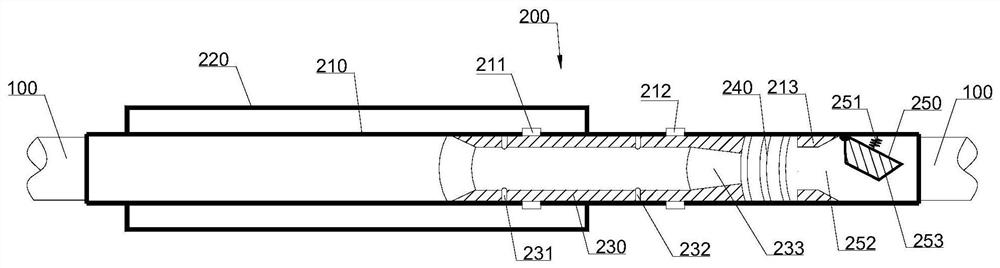

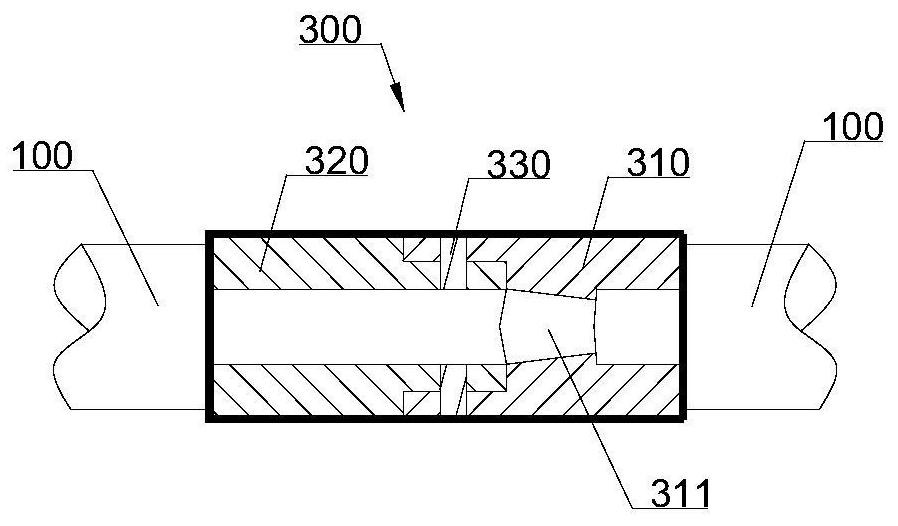

[0045] The embodiment of the present invention provides a water-resisting layer enhanced grouting reconstruction device based on staged fracturing such as Figure 1-Figure 9 As shown, it includes at least two sections of fracturing grouting controller 200 that pass through the high-pressure fracturing string 100 in series and are placed in the borehole 800. The cracking pipe string 100 is connected outside the borehole 800, and the high pressure fracturing pipe string 100 between the fracturing grouting controllers 200 is equipped with a safety throwing device 300 in series.

[0046] refer to figure 1 , image 3 and Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com