Construction device for slotting transverse seam and vertical seam of wall body

A construction device and vertical seam technology, applied in the field of grinding tools, can solve problems such as low construction safety, slow grinding, and poor construction quality, and achieve the effects of reducing safety risks, increasing construction speed, and good construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

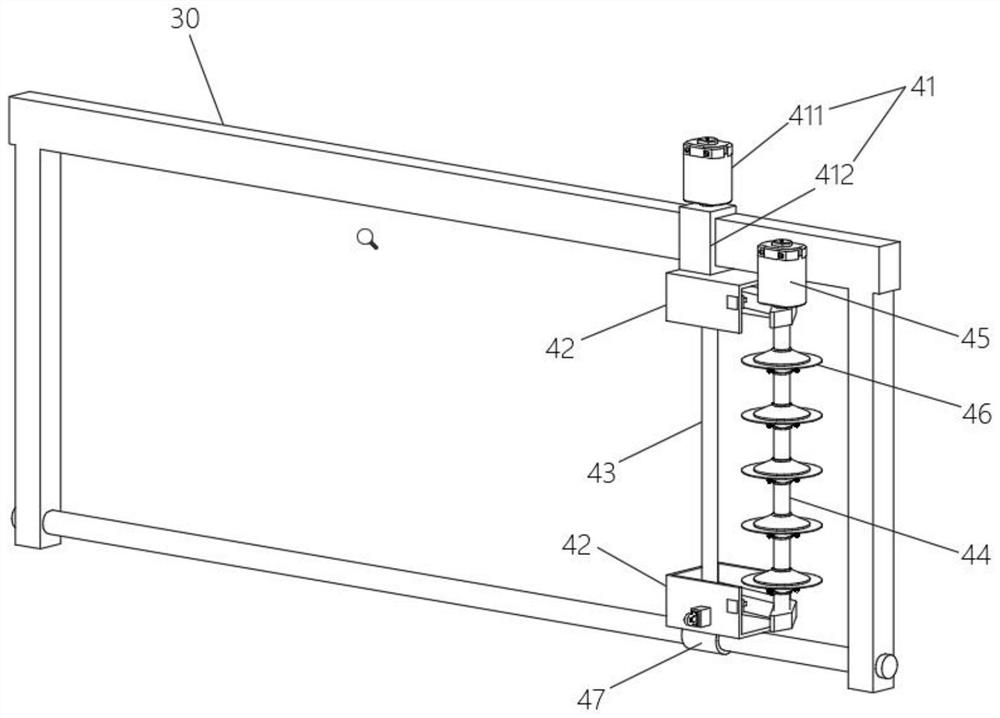

[0068] Such as figure 1 As shown, the present embodiment provides a construction device for synchronous opening of horizontal seams and vertical seams of walls, and the construction device includes guide rail 10, lifting device 20, tire frame 30, transverse seam grinding mechanism 40 and vertical seam Grinding mechanism 50.

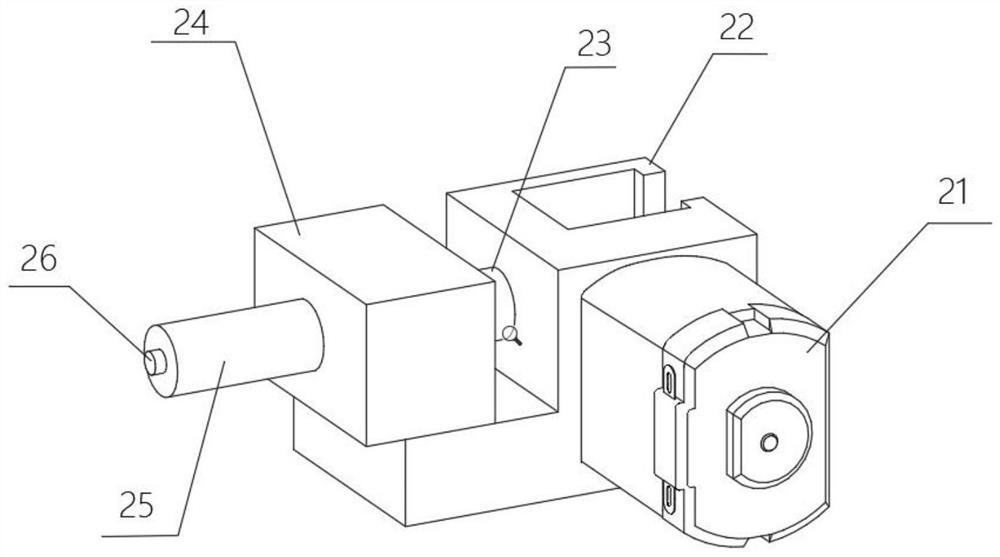

[0069] combine figure 1 and figure 2 As shown, the two guide rails 10 are arranged in parallel and at intervals; the lifting device 20 is arranged on the guide rails 10 and can move along the length direction of the guide rails.

[0070] Combine below Figures 1 to 2 and Figure 23 , Figure 24 As shown, the connection method of the guide rail is further described. When opening the wall 1, the guide rail 10 is fixed on the scaffold 2. Of course, the guide rail 10 can also be fixed on other support structures, and the structural form of the support structure is not limited. Further, a verticality adjustment device is provided on the opposite side o...

Embodiment 2

[0089] This embodiment provides a construction method for synchronous opening of horizontal joints and vertical joints of the wall, the following in conjunction with Embodiment 1 and Figure 1 to Figure 24 Describe the construction method further. The construction methods include:

[0090] S1. Set up a supporting device at a suitable position of the wall 1 to be constructed, and install a construction device for synchronous opening of the horizontal and vertical joints of the wall; The construction equipment specifically includes:

[0091] S1-1. Two guide rails 10 are vertically spaced and fixed on the support device, and the side of the guide rail facing the wall 1 is provided with climbing teeth 11 along the height direction;

[0092] S1-2. A lifting device 20 is provided on the guide rail 10, the lifting device includes a lifting drive motor 21, and the lifting drive motor can drive the lifting device to move along the length direction of the guide rail;

[0093] S1-3. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com