Forward osmosis membrane and preparation method thereof

A forward osmosis membrane and membrane structure technology, applied in the field of polymer separation membrane preparation, can solve the problems of insufficient antibacterial efficiency, weak antibacterial effect, and affecting membrane performance, so as to improve forward osmosis, comprehensive antibacterial effect, and inhibit breeding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

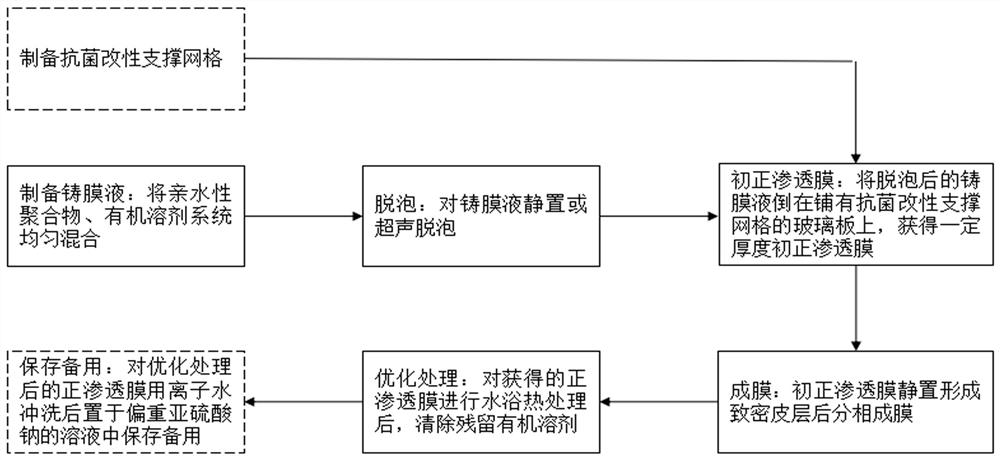

[0046] The preparation method scheme of the forward osmosis membrane provided by the invention is further described as follows:

[0047] Preparation of nano-Ag / TiO2 modified polyester mesh: add nano-Ag at 0.1-0.5 wt.% by mass percentage and nano-TiO2 at 0.2-1wt.% by mass percentage to polyethylene with a mass percentage of 2-8 wt.% In the alcohol aqueous solution, the suspension was obtained by ultrasonic dispersion, and the polyester mesh was impregnated with the suspension, and then dried naturally for later use;

[0048] Preparation of casting solution: Add 8-15wt.% of cellulose triacetate to 5-20 wt.% of acetone, 5-10 wt.% of methanol and 6-8% of lactic acid wt.%, and the rest is 1,4-dioxane, after stirring at 40°C for 24 hours, a uniform casting solution is obtained; the obtained casting solution is left to stand for 24 hours to fully defoam or assist Ultrasonic defoaming;

[0049] Pour the completely defoamed casting solution on a glass plate covered with a prepared mo...

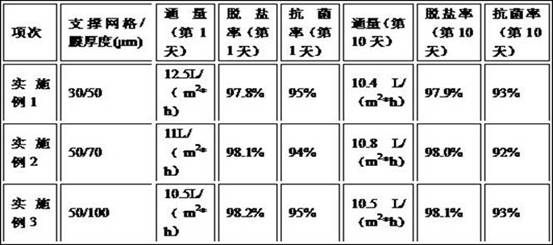

Embodiment 1

[0054] 1. Soak the polyester screen with a thickness of 30 μm and a pore size of 100 mesh with 2% hydrochloric acid and 10% sodium hydroxide for 1 hour to remove impurities adsorbed on the surface, then rinse with deionized water, and dry for later use;

[0055] 2. Prepare nano-Ag, nano-TiO Modified polyester mesh: 0.2wt.% by mass percentage of nano-Ag, nano-TiO2 by mass percentage 0.4wt.%, join in the polyvinyl alcohol aqueous solution of mass percentage 4wt.%, Ultrasonic dispersion is used to obtain a suspension, which is impregnated with a polyester mesh and dried naturally for later use;

[0056] 3. Add cellulose triacetate at a mass percentage of 13 wt.% to 1,4-dioxane with a mass percentage of 54 wt.%, acetone with a mass percentage of 19 wt.%, methanol with a mass percentage of 8 wt.% and lactic acid In the mixed solution with a mass percentage of 6%, after stirring at a temperature of 40°C for 24 hours, a uniform casting solution was obtained;

[0057] 4. Leave the ca...

Embodiment 2

[0064] 1. Soak the polyester mesh with a thickness of 50 µm and a pore size of 100 mesh with 2% hydrochloric acid and 10% sodium hydroxide for 1 hour to remove impurities adsorbed on the surface, then rinse with deionized water, and dry for later use;

[0065] 2. Preparation of nano-Ag, nano-TiO2 modified polyester mesh: 0.2wt.% of nano-Ag by mass percentage, 0.4wt.% of nano-TiO2 by mass percentage, join in the polyvinyl alcohol aqueous solution of 4wt.% by mass percentage , through ultrasonic dispersion, to prepare a suspension, after impregnating the suspension with a polyester mesh, and drying it naturally for later use;

[0066] 3. Add cellulose triacetate at a mass percentage of 13 wt.% to 1,4-dioxane with a mass percentage of 54 wt.%, acetone with a mass percentage of 19 wt.%, methanol with a mass percentage of 8 wt.% and lactic acid In the mixed solution with a mass percentage of 6%, after stirring at a temperature of 40°C for 24 hours, a uniform casting solution was ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com