Injection molding blind end collector plate and fuel cell

A technology of current collectors and injection molding plastics, which is applied to fuel cells, fuel cell parts, circuits, etc., can solve the problems of easy loosening during use, complicated production and assembly processes, affecting the working stability of fuel cells, etc. Insulation effect, simplified assembly process, effect of saving interior space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

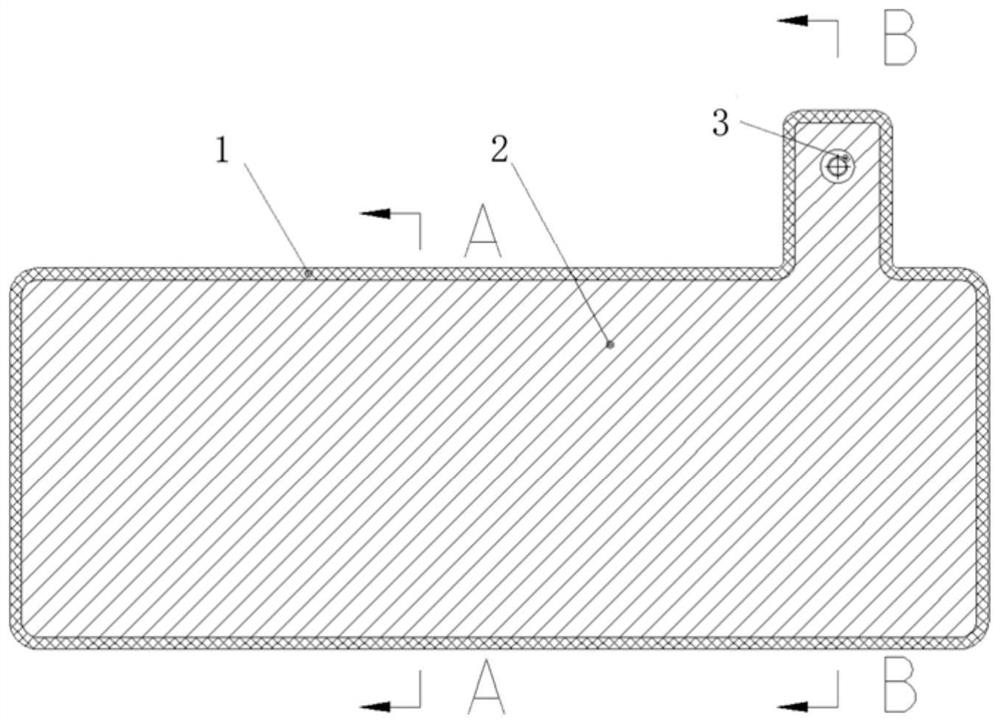

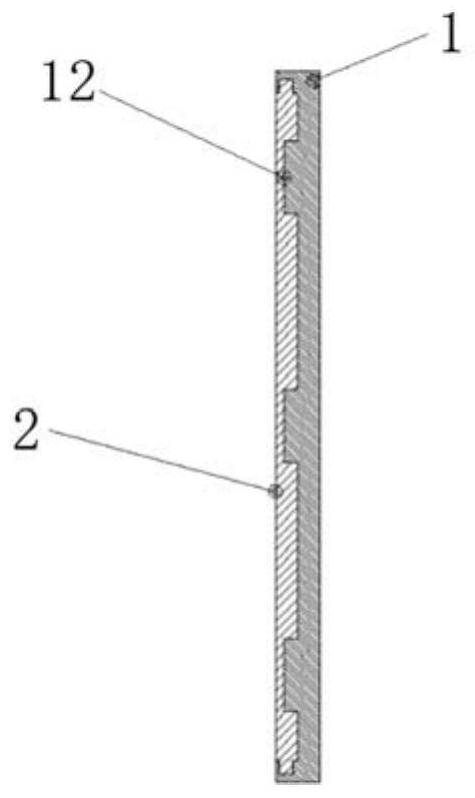

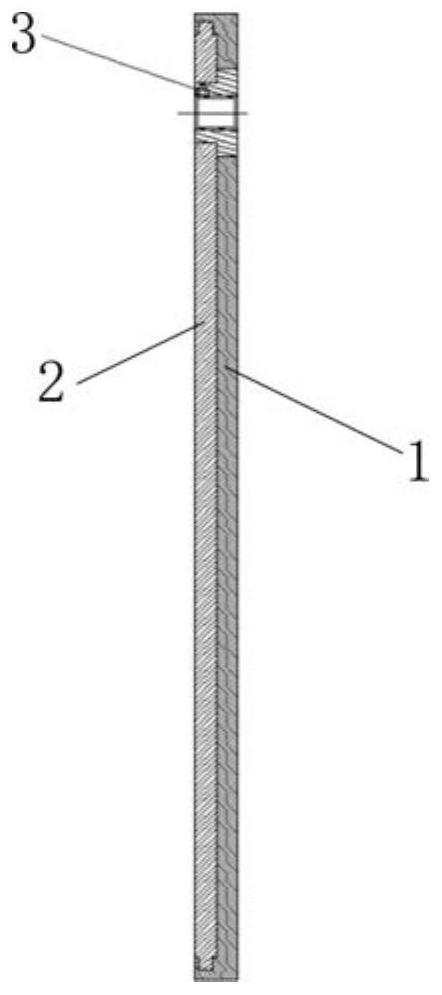

[0028] Such as Figure 1~5 As shown, this embodiment provides an injection molded blind end collector plate, including an injection molded plastic plate 1 and a metal collector plate 2. The metal current collecting plate 2 is installed in the fitting groove 11 so that the injection molded plastic plate 1 covers the back and the side of the metal current collecting plate 2, and the front of the metal current collecting plate 2 is exposed for contacting the stack core of the fuel cell. The edge of the metal collector plate 2 can be in a convex shape, which is snapped into the recess on the side wall of the fitting groove 11 to improve the connection strength.

[0029] Protruding pillars 12 are distributed on the bottom surface of the fitting groove 11, and grooves 21 corresponding to the position of the raised pillars 12 are distributed on the back of the metal current collecting plate 2. When the metal collecting plate 2 is installed in the fitting groove 11 , the protruding p...

Embodiment 2

[0032] Such as Figure 6 As shown, this embodiment provides a fuel cell, including the core 4, the end plate 5 and the injection-molded blind-end collector plate described in Embodiment 1. The injection-molded blind-end collector plate is fixed between the core 4 and the end plate 5 . With this structure, there is only an injection molded blind end collector plate between the end plate 5 and the core 4, which simplifies the assembly process; at the same time, the injection molded plastic plate 1 covers the back and side of the metal collector plate 2, which not only enhances the insulation effect, but also It can be used as a buffer engaging part connected with the end plate 5 to improve the accuracy and stability after assembly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com