Comprehensive control system for nuclear power plant BOP process and method thereof

A technology of comprehensive control and technological process, applied in the direction of electrical program control, general control system, control/regulation system, etc., can solve the problems of large scale, unfavorable operation and maintenance, and high operating cost of the main DCS of the power plant, and reduce the frequency of on-site inspections , reduce the number of spare parts, reduce the effect of operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

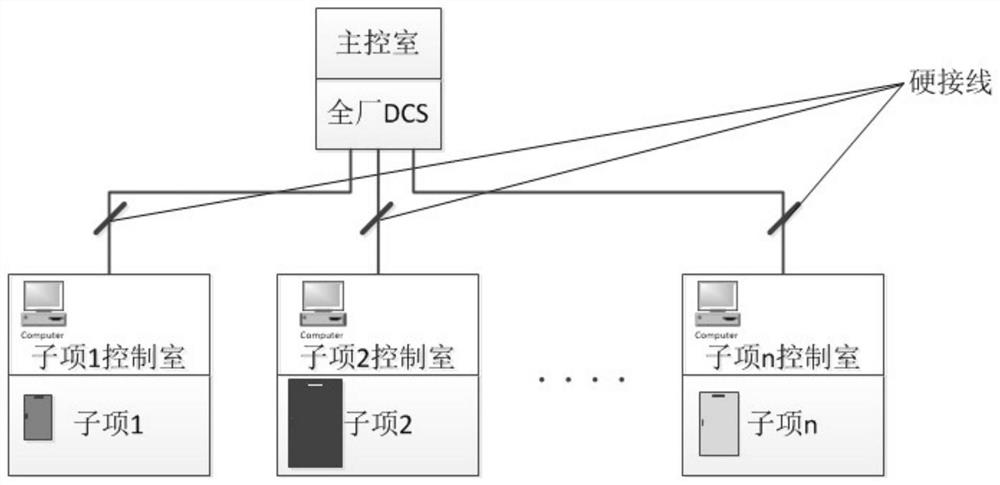

Problems solved by technology

Method used

Image

Examples

Embodiment

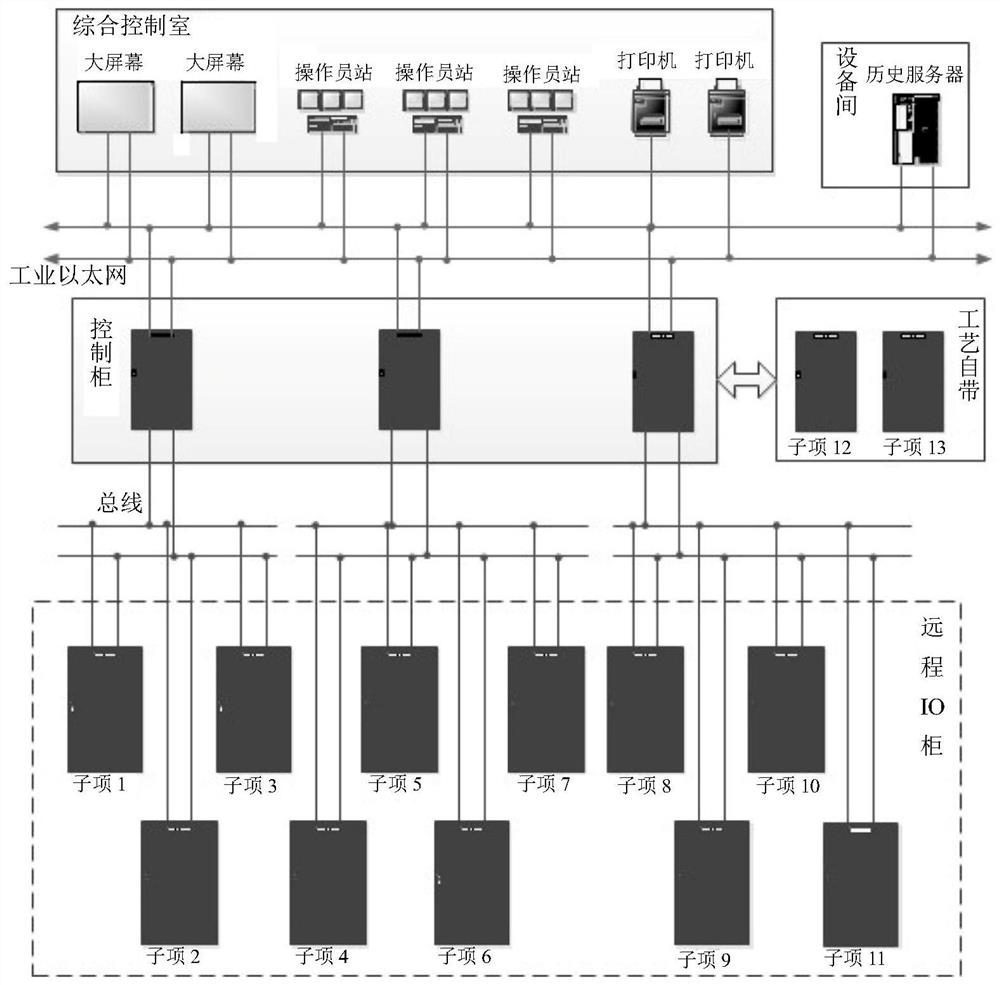

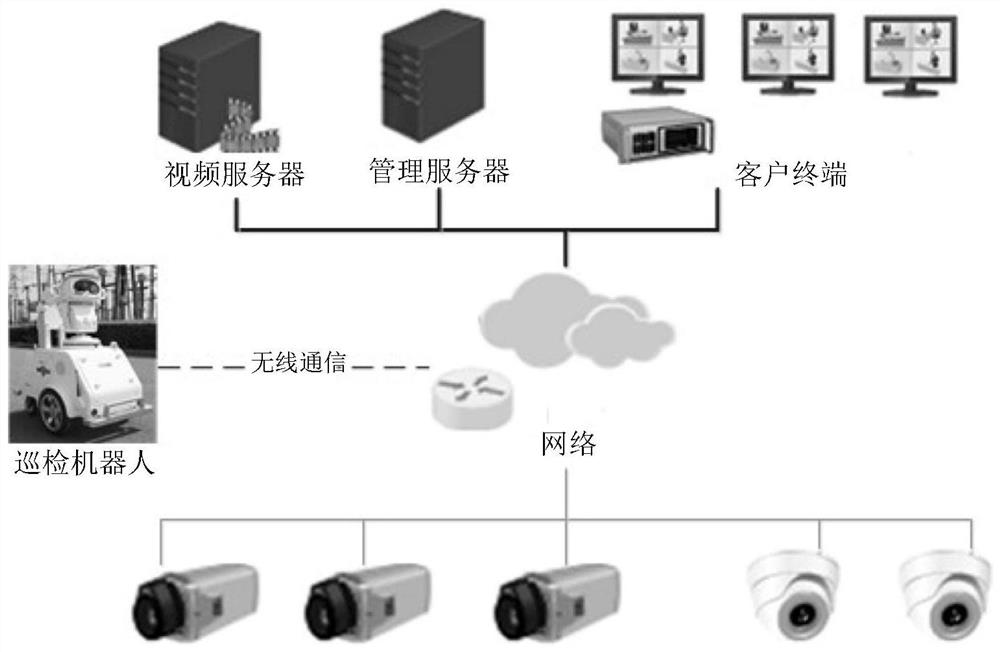

[0026] The comprehensive control system for BOP process of a nuclear power plant provided in this embodiment includes BOP process control equipment, related video / image recognition equipment and inspection equipment, figure 2 It is a schematic diagram of the overall structure of the BOP process control system of a nuclear power plant. The system includes remote I / O cabinet, control cabinet, man-machine interface equipment (operator station, large screen) and related auxiliary equipment (printer, history server, etc.). In this embodiment, the BOP comprehensive control room is set independently, and the operator station, large screen, and printer are set in the BOP comprehensive control room. The system adopts a unified control platform, which is shared by all sub-items, and PLC or small DCS can be used. Spare parts only need to be purchased based on this control platform model, and its quantity is greatly reduced compared with the previous control method. The unification of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com