Multi-optical axis parallel calibration method for ground laser terminal based on star sensor

A star sensor and calibration method technology, which is applied in the field of laser communication, can solve the problems of few calibration states, inconvenient outdoor use, and high elevation angle state cannot be calibrated, etc., and achieve the effect of full calibration range and simple calibration method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] According to the method proposed by the present invention, the optical ground station (position: longitude 118.85°, latitude 32.10°, height 63m) of Nanjing Yingtian Optical Company in Chaoyang Mountain, Nanjing was calibrated with multiple optical axes.

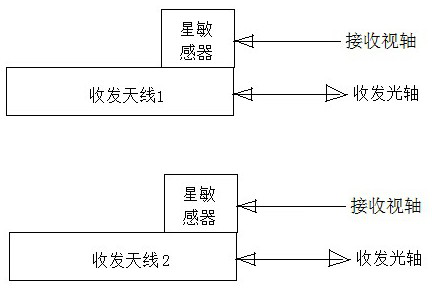

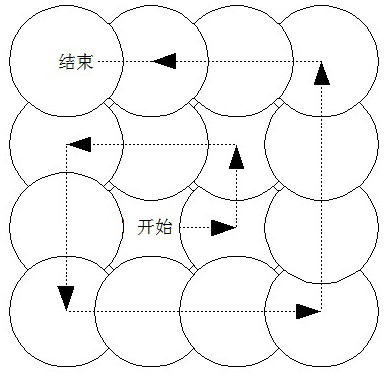

[0022] Install the star sensor next to the transceiver antenna of the ground laser terminal. In the ground laser terminal, there are generally 3 to 5 transceiver antennas that keep the optical axes parallel. In the method of the present invention, each transmitting and receiving antenna is required to be equipped with a star sensor for calibrating the optical axis. Adjust the receiving boresight of the star sensor to be parallel to the optical axis of the transceiver antenna. According to the ground position of the ground laser terminal and the star map information, 15 stars are selected as the multi-optical axis parallel calibration calibration source, and they are evenly distributed in the terminal at the position req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com