Vacuum microwave smelting device

A vacuum microwave and microwave technology, which is used in stirring devices, crucible furnaces, furnaces, etc., can solve problems such as affecting the melting effect and hot spots of the working medium, and achieve the effects of shortening the process time, uniform statistics, and high safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

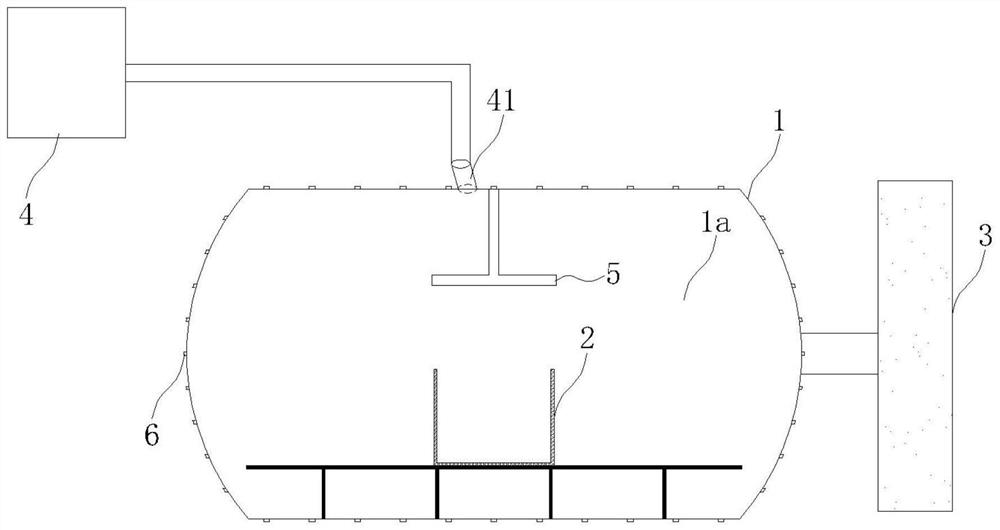

[0053] Such as figure 1 , 4 As shown, a vacuum microwave smelting device in this embodiment includes a horizontal furnace body 1 with a cavity 1a, a microwave gap is arranged on the furnace body 1, a support frame 11 is set in the cavity 1a, and a support frame (11) is set Insulation board 21; furnace body 1 consists of hatch, hatch head, hatch flange, door handle, observation window, cylinder, hinge, locking mechanism, rotating mechanism, microwave feeder and corresponding interface flanges Each interface on the furnace body 1 is vacuum-sealed and electromagnetically shielded; the diameter of the cavity 1a is 1200mm, and the length of the furnace body 1 is 1500mm;

[0054] A silicon carbide crucible 2 is arranged on a heat shield 21, and an insulation layer 22 is arranged outside the crucible 2, and the temperature safety of the furnace body 1 is ensured by the fact that the crucible 2 does not directly contact the furnace body 1;

[0055] The vacuum system 3 communicates ...

Embodiment 2

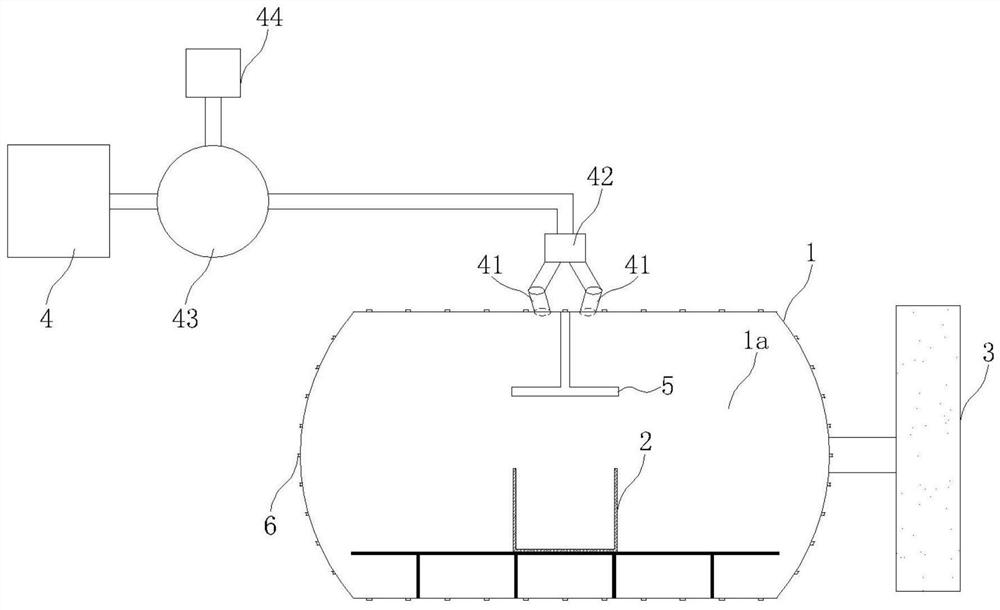

[0061] As an alternative to Embodiment 1, this embodiment is based on Embodiment 1, such as figure 2 As shown, the wave source 4 is connected to the circulator 43, the transmission port of the circulator 43 is connected to the rectangular waveguide 41, the reflection port of the circulator 43 is connected to the absorbing load 44, the rectangular waveguide 41 is connected to the 1-to-2 power splitter 42, and the two-way power splitter 42 The microwave ports are respectively connected through the rectangular waveguide 41 converters, which is more conducive to uniform heating.

Embodiment 3

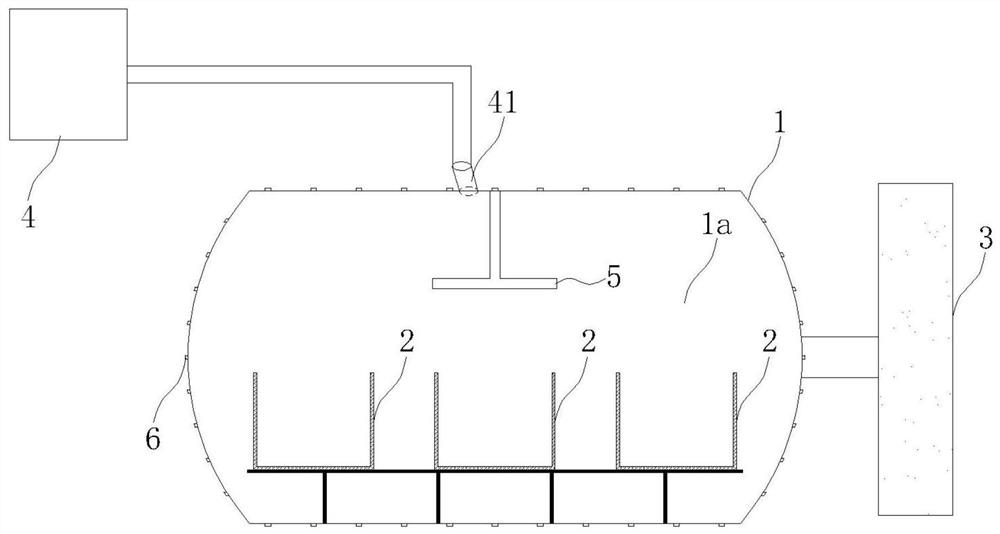

[0063] As an alternative to Embodiment 1, this embodiment is based on Embodiment 1, such as image 3 As shown, three crucibles 2 are arranged on the heat shield 21, and an insulation layer 22 is arranged outside each crucible 2, so as to realize simultaneous heating of multiple stations and improve melting efficiency.

[0064] As an optional mode of the above-mentioned embodiment, in other embodiments, the microwave mouth is facing the stirring paddle 5, which is beneficial to the stirring paddle 5 to make the electromagnetic field in the cavity 1a uniform; The gap angle cannot be 180°C to prevent microwave reflection, and the phases of each road are consistent.

[0065] As an optional mode of the above-mentioned embodiment, in other embodiments, the stirring paddle 5 is a metal stirring paddle 5, and the rotation diameter of the stirring paddle 5 is not less than 1 / 4 of the microwave wavelength, and more preferably the rotation diameter of the stirring paddle 5 is the microwa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com