Variable braking force device of high-sensitivity brake

A brake and braking force technology, applied in the direction of brake actuators, gear transmission mechanisms, mechanical equipment, etc., can solve the problems of increasing the manufacturing cost of disc brakes, increasing the weight and layout space of disc brakes, etc. The effects of manufacturing cost and layout space, improved braking force, and simple design structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

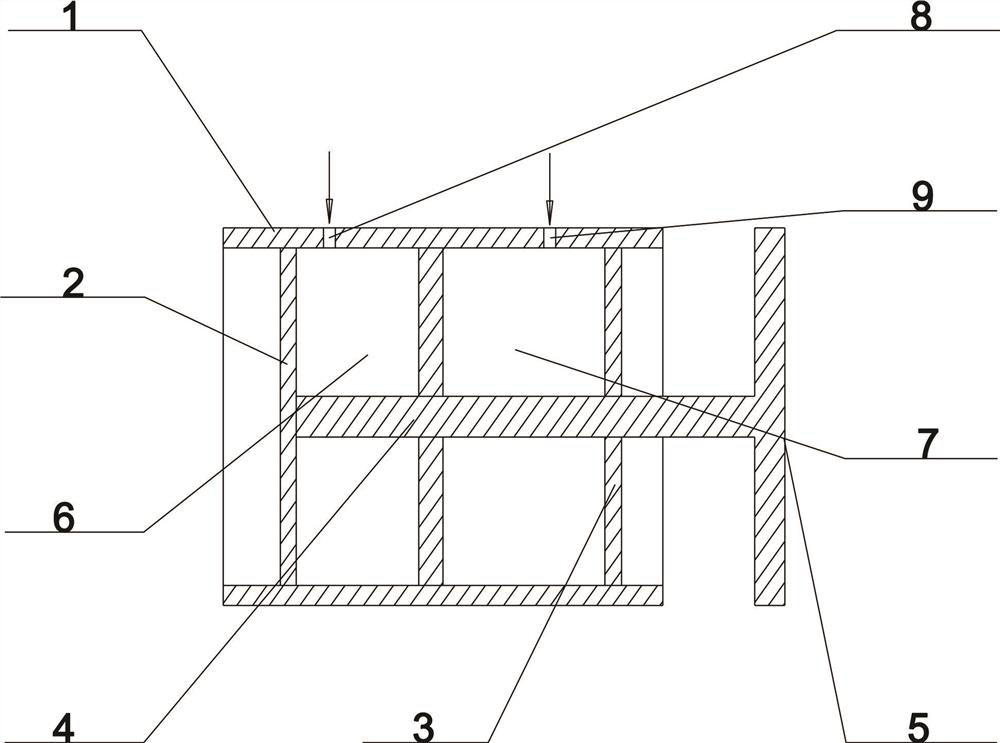

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0020] As shown in the figure, a variable braking force device of a highly sensitive brake includes a brake cylinder 1, a first piston 2, a second piston 3, a brake lever 4, and a brake shoe 5; the brake cylinder 1 is Hollow cylindrical type with both ends closed, the first piston 2 is fixedly arranged in the brake release chamber 5 of the brake cylinder 1, and the second piston 3 is fixedly arranged at the position near the right side of the brake lever 4 The left end of the brake rod 4 is fixedly connected to the middle position on the right side of the first piston 2, and the right end of the brake rod 4 passes through the brake chamber 7 and extends to the outside of the right side of the brake cylinder 1; The moving shoe 5 is fixedly arranged at the right end of the brake lever 4; the brake release chamber 6 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com