Basement outer formwork integrated structure and construction technology thereof

It is a technology of external formwork and basement, which is applied in the direction of building components, building structures, building insulation materials, etc. It can solve the problems of waterproof, thermal insulation effect, long construction time of walls, etc., and achieve good thermal insulation effect, Effect of improving waterproof ability and improving molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

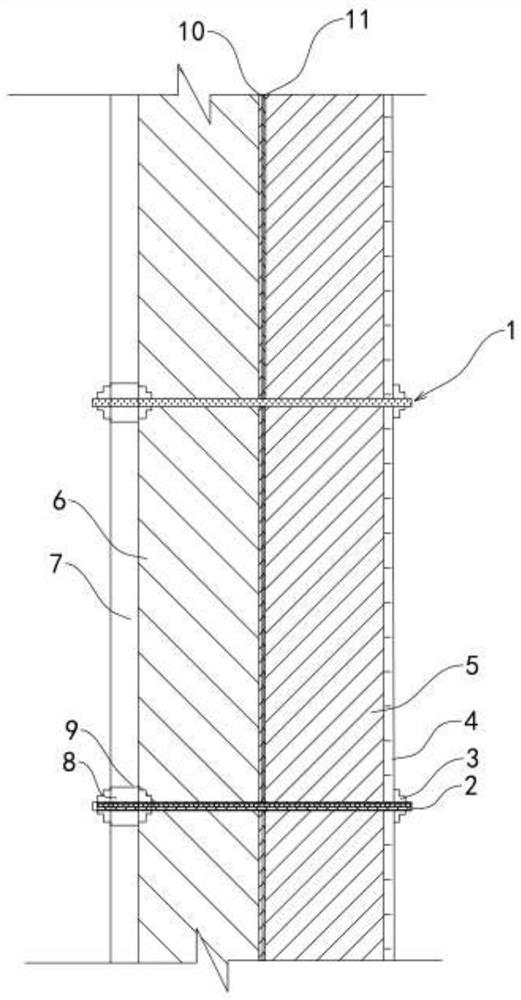

[0033] refer to figure 1 , is an integrated structure of basement external formwork disclosed in this application, including an inner module and an outer module, a pouring model is formed in the inner module and the outer module, and an installation module and an outer module are formed in the basement. After the layer module, pour concrete into the formed pouring model, and wait for the poured concrete to solidify to form the cast-in-place concrete layer 5 . The inner layer module and the outer layer module are also provided with a fixing component 1, and the fixing component 1 is used to fix the position of the inner layer module and the outer layer module, so as to improve the stability and firmness of pouring concrete.

[0034] The inner module is set as a concrete inner formwork 4, and the outer module includes an outer insulation layer 6 and an outer formwork fixing keel 7. The concrete inner formwork 4 and the outer insulation layer 6 are arranged parallel to each other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com