Ultra-low basis weight corrugating base paper and preparation method thereof

A corrugated base paper, ultra-low technology, applied in papermaking, paper machine, paper recycling, etc., can solve the problems of flow system pollution, inability to continuously produce low-gram weight corrugated base paper products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

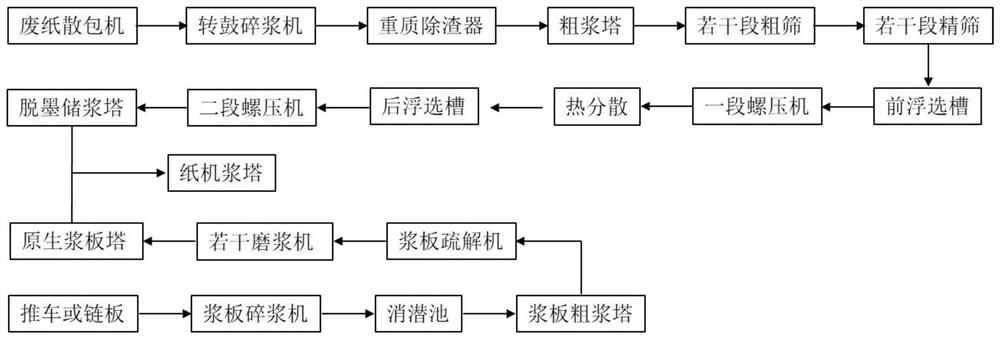

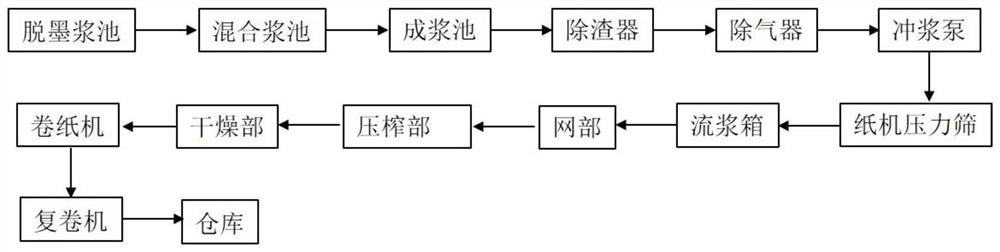

Method used

Image

Examples

Embodiment 1

[0039]Corrugated base paper is made of 500 kg of imported American waste 8#, 200 kg of European waste A9, 100 kg of Daolin paper in Hong Kong, 150 kg of old newspapers in Hong Kong, and 50 kg of European 37# waste paper The obtained deinked pulp (1000 kilograms of total air-dried weight), according to the above-mentioned corrugated pulp preparation process and corrugated base paper preparation process, added 10-15kg AKD sizing agent, Jiangsu Fumiao retention aid VG727 200g in the sizing process.

[0040] Prepared 40g / m 2 The paper break length of corrugated base paper is 5KM, and the water absorption value of the paper is 30g / m 2 , the water contained in the paper is 7.5%, and the tightness is 0.58g / cm 2 , burst index 1.6kPa m 2 / g.

Embodiment 2

[0042] Corrugated base paper is deinked pulp made from 150 kg air-dried old newspapers in the Mainland, 500 kg air-dried mixed office waste paper in the Mainland, 50 kg air-dried Daolin paper in Hong Kong, China, and 100 kg air-dried old newspapers in Hong Kong, China (air-dried 800kg), chemical-mechanical pulp (200 kg of air-dried weight), according to the above-mentioned corrugated pulp preparation process and corrugated base paper preparation process, add 10-15kg AKD sizing agent in the sizing process, Jiangsu Fumiao retention aid VG727 200g, suitable Ryan cationic starch 880L 3kg, Pacific Chemical Company fixative PPT-400 600g.

[0043] Prepared 40g / m 2 The paper break length of corrugated base paper is 5.2KM, and the water absorption value of the paper is 25g / m 2 , the water contained in the paper is 7%, and the tightness is 0.54g / cm 2 , burst index 1.8kPa m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com