Printing and slotting machine with all-servo paper feed system in paper feed part

A technology of paper feeding system and slotting machine, which is applied in the direction of paper/cardboard containers, papermaking, container manufacturing machinery, etc. It can solve the problems of increasing paper jams, cardboard cracks, and not being able to meet the requirements of the market.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

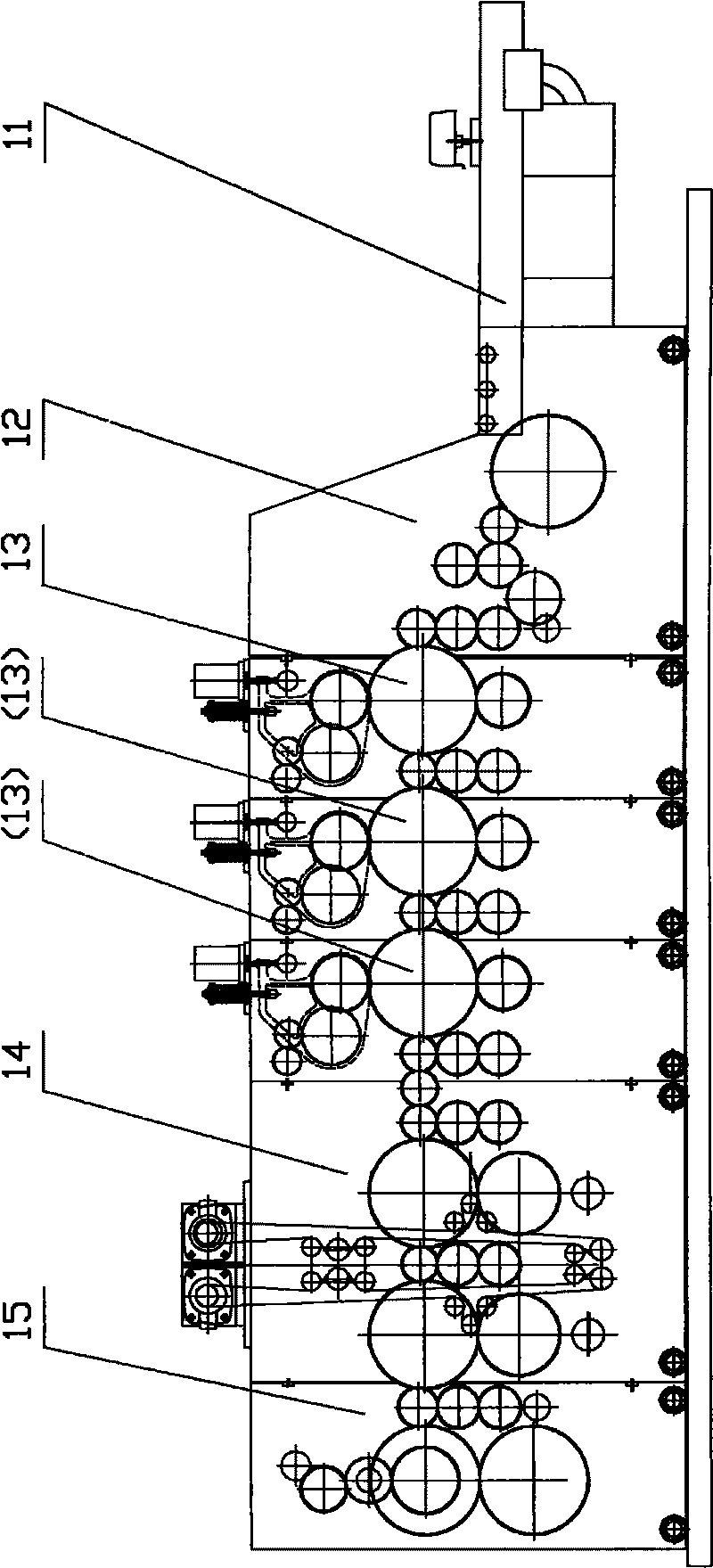

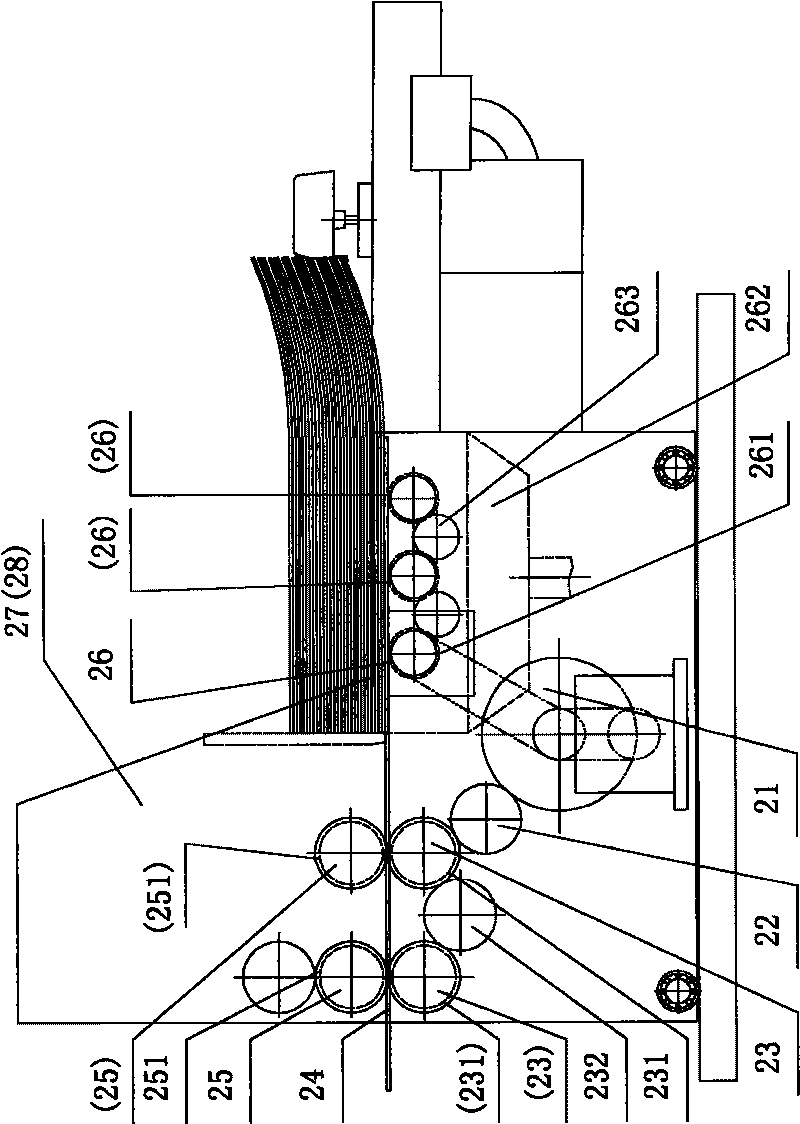

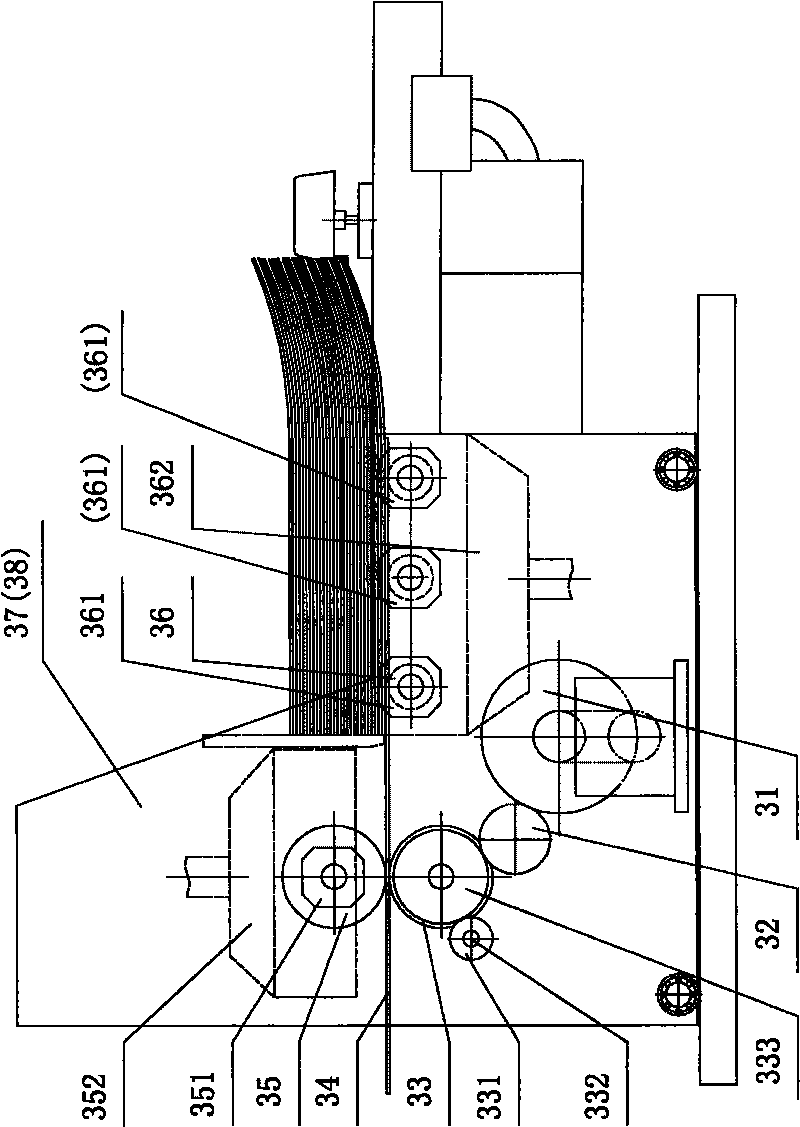

[0010] The main structure of the printing slotting machine with full servo system in the paper feeding part of the present invention is as follows: figure 1 As shown, it mainly includes leading edge paper feeding unit, paper feeding unit, multiple printing units, slotting unit and die-cutting unit. Among them, the paper feeding part composed of the leading edge paper feeding unit and the paper feeding unit is equipped with a full servo paper feeding system, and the main structure is as follows: image 3 , Figure 4 As shown, it comprises three groups of paper feeding rollers 36 installed between the wallboards 37, 38 on both sides of the front end of the paper feeding part, and three identical servo motors 361 are respectively housed at the axle ends on one side of the three groups of paper feeding rollers, and are connected with the three groups of paper feeding rollers. The shafts of the paper feeding rollers are connected by fixed transmission, and each servo motor indepen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com