High-speed measuring automatic rotary packaging machine for noodles

A technology of automatic rotation and packaging machine, applied in packaging, transportation packaging, transportation and packaging, etc., to achieve the effects of accurate measurement, high degree of automation, and improved packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention are further described below with reference to the accompanying drawings.

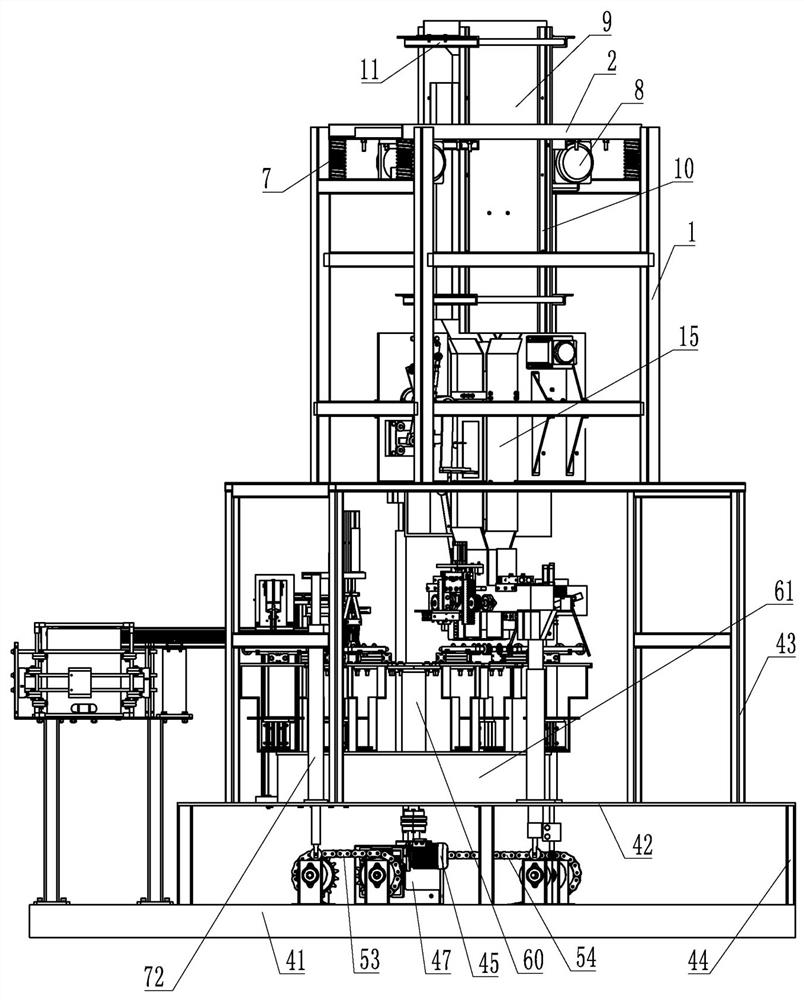

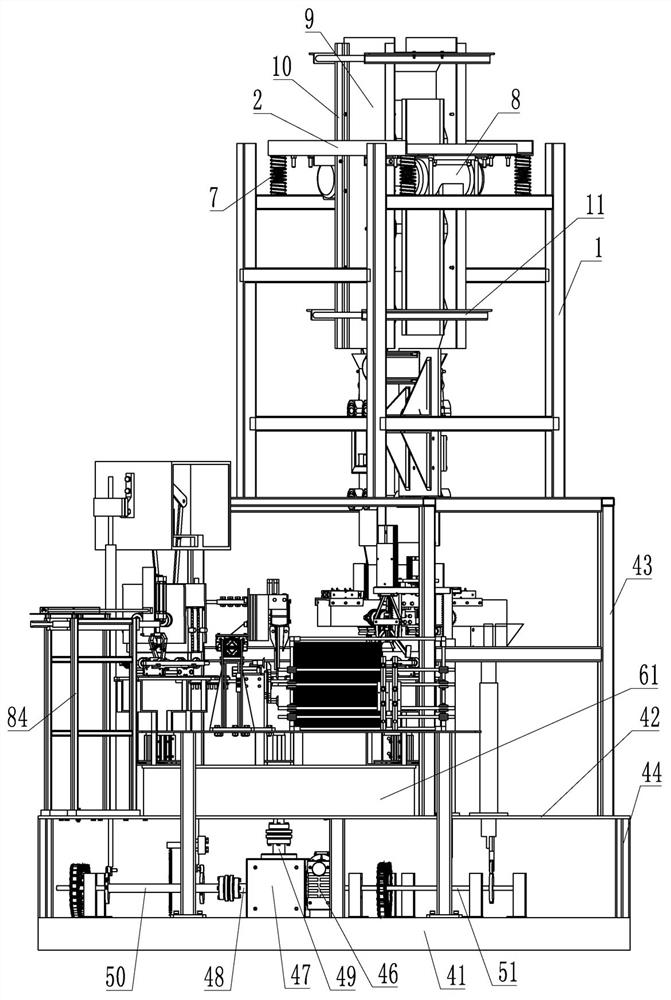

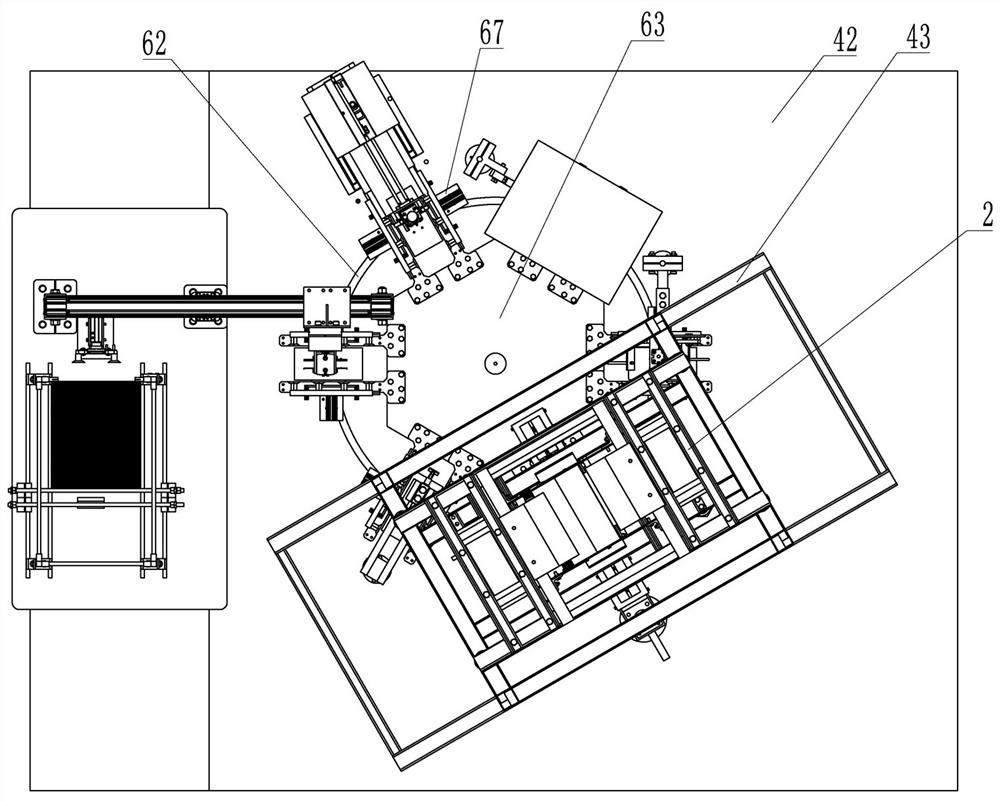

[0038] like Figure 1-Figure 17 As shown, the automatic high-speed measuring automatic rotary packaging machine for noodles includes a base 41, a working platform 42, a power module, a support frame 43, a rotary module, a bag supply module, a bag opening and blowing module, a blanking and filling module, a shaping module, and a heat sealing module. Module, bag unloading module and noodle high-speed metering module, the base 41 is fixedly installed on the ground, the bottom of the working platform 42 is fixedly installed on the upper surface of the base 41 through a number of first legs 44, and the power module is installed on the upper surface of the base 41 And it is located below the working platform 42, the rotary module is rotatably arranged above the working platform 42, the bag supply module is installed on the left side of the upper surface of the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com