Filter pipe forming device

A molding device and filter tube technology, applied in ceramic molding machines, manufacturing tools, molds, etc., can solve the problems of reducing the vacuum inside the drum, aggravating equipment wear, and increasing the weight of rotating parts, so as to increase the drainage point and improve the quality , Improve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

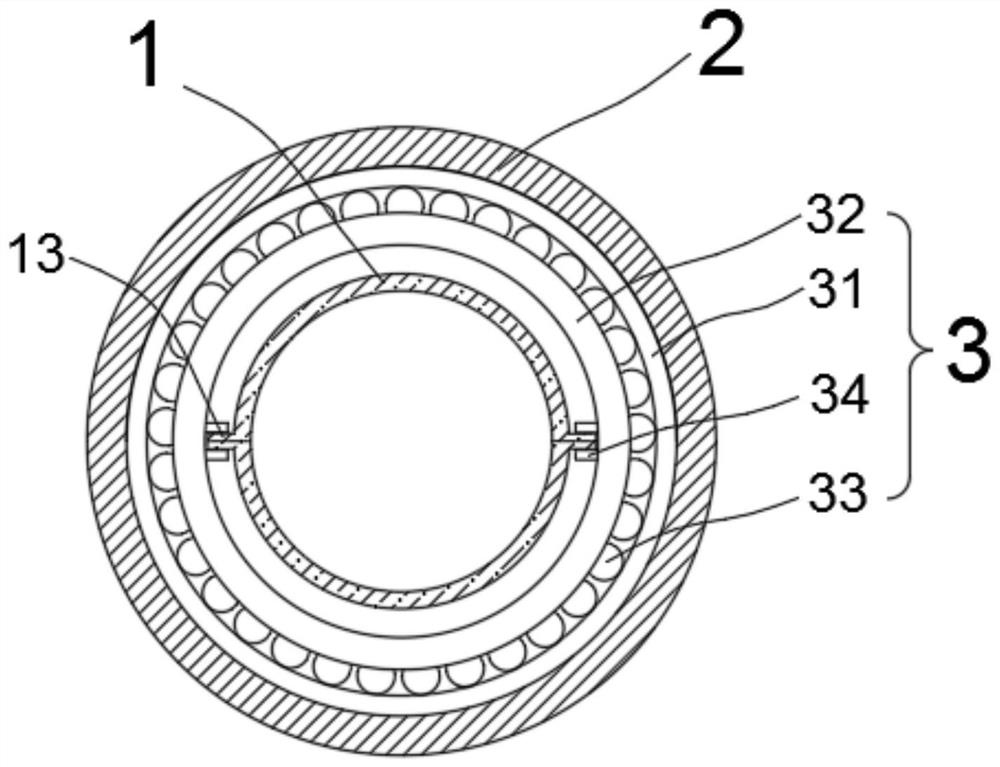

[0033] Specifically, as figure 1 As shown, the housing 1 is a cylindrical body 21 with one end closed, and a liquid discharge port 24 is provided at the closed end of the cylindrical body 21, and three liquid discharge ports 24 are provided at the bottom of the cylindrical body 21, and the three liquid discharge ports are evenly distributed in the cylinder. In the length direction of the body 21, the liquid discharge port 24 is connected to the negative pressure mechanism through a pipeline, and is used to suck the slurry out of the cylinder body, so that the cylinder body is in a vacuum state; one end of the cylinder body 21 opening is provided with a sealing cover 22, and A feed pipe 23 is provided, and the feed pipe 23 extends into the cylinder and extends into the molding die 1 .

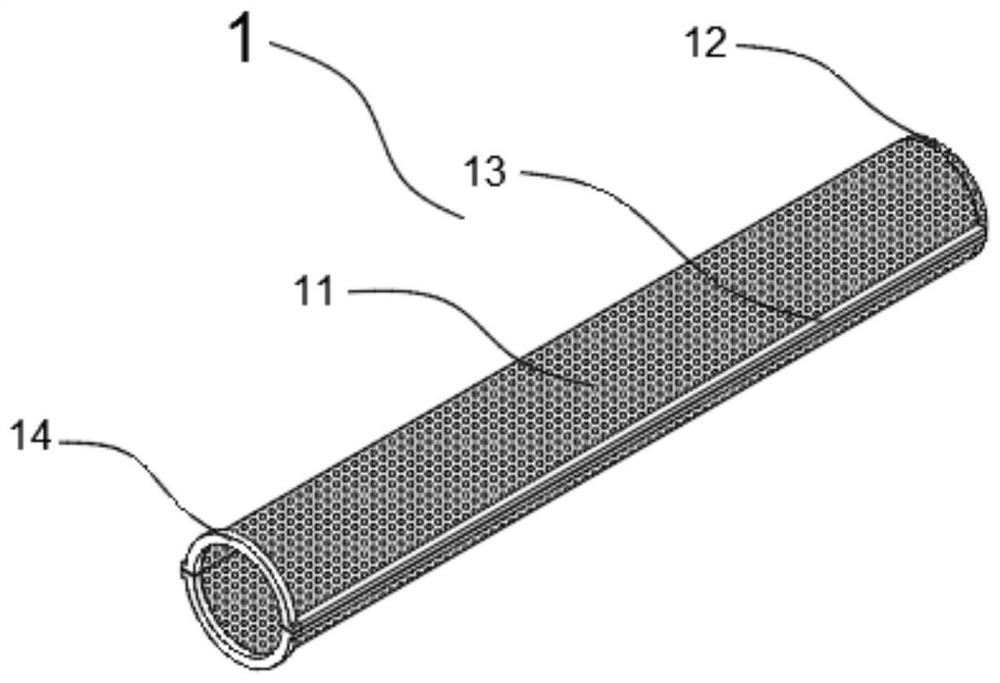

[0034] Such as figure 2 As shown, the molding die 1 includes a tubular body 11 and a bottom cover 12, the bottom cover 12 is provided with a coupling 42, the tubular body 11 is surrounded by t...

Embodiment 2

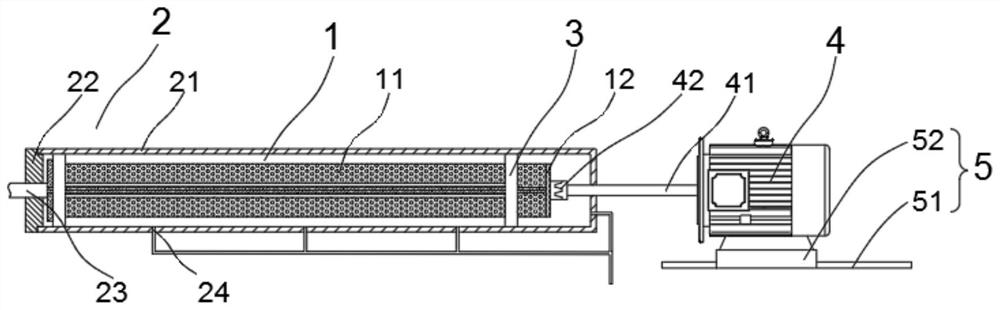

[0040] Such as Figure 4 A filter tube molding device shown includes a molding die 1, a casing 2, a rotating mechanism 3, a drive motor 4 and a negative pressure mechanism (not shown), the casing 2 is an openable airtight casing, and the casing 2 is provided with The feed pipe 23 and the liquid discharge port 24, the feed pipe 23 communicates with the forming mold 1, the liquid discharge port 24 is connected with the negative pressure mechanism; the rotating mechanism 3 is arranged in the shell 2, the forming mold 1 is connected with the rotating mechanism 3, and the driving motor The driving shaft 41 of 4 extends into the housing 2 and is connected with the rotating mechanism 3 for driving the forming mold 1 to rotate.

[0041] Specifically, as Figure 4 As shown, the housing 2 includes an upper half pipe 25 and a lower half pipe 26, the cross section of the upper half pipe 25 is smaller than the cross section of the lower half pipe 26, and the two ends of the upper half pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com