Concrete filling device for prefabricated panel processing

A filling device and plate processing technology, which is applied in the direction of clay preparation device, supply device, manufacturing tools, etc., can solve the problems that concrete is prone to dryness and waste of concrete resources, etc., achieve good shock absorption effect, prevent dryness, and improve fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] see Figure 1-11 , the present invention provides a technical solution: a concrete filling device for prefabricated plate processing, characterized in that: comprising

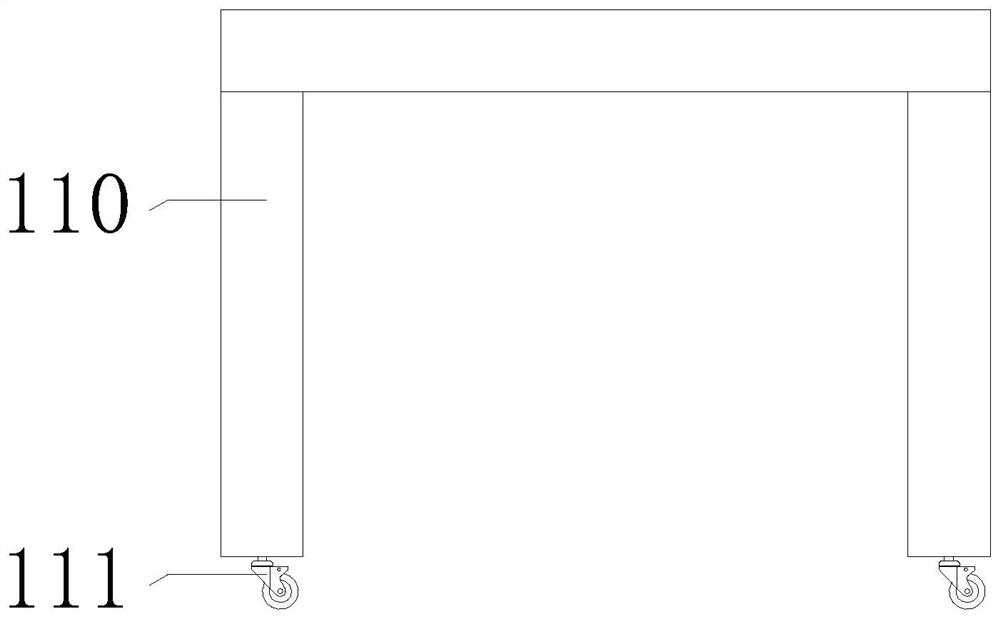

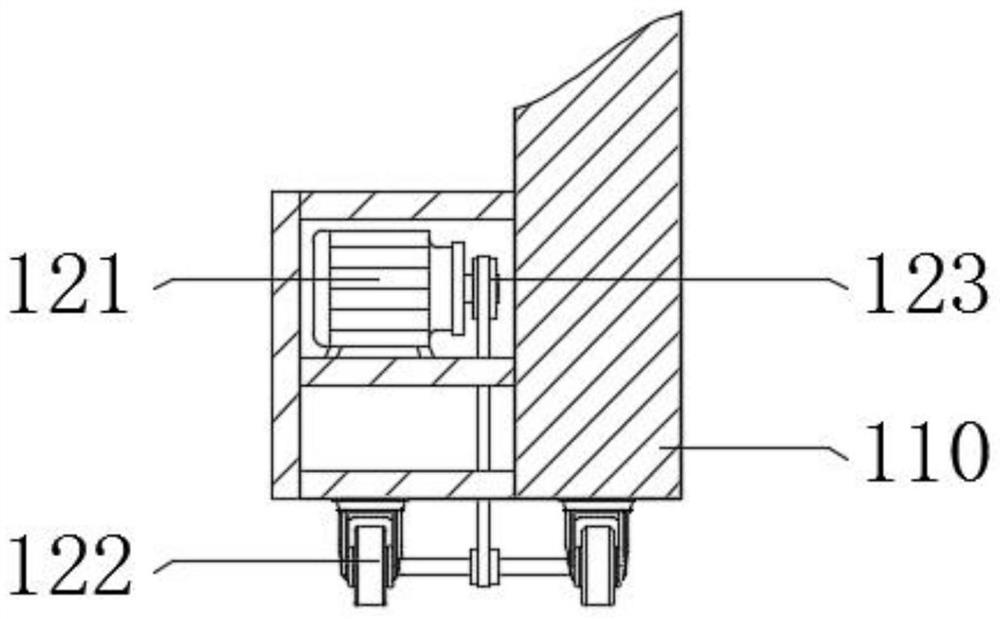

[0048] A frame (100), the frame (100) comprising a frame body (110) and a mobile vehicle body (120), the mobile vehicle body (120) being fixedly installed on both sides of the frame body (110);

[0049] A pouring assembly (200), the pouring assembly (200) comprising a linear guide rail (210), a hopper (220), a support (230), a sliding frame (240), an electric push rod (250) and a baffle (260);

[0050] Stirring assembly, the stirring assembly includes a mixing drum 270, a horizontal plate 300, a support frame 310, a transmission shaft 320, a stirring rod 330 and a stirring motor 340, the mixing drum 270 is arranged inside the hopper 220, and the upper part of the mixing drum 270 is Cylindrical shape, the lower part is in the shape of an inverted circular table, the bottom of the mixing drum 270 is prov...

Embodiment 2

[0055] see Figure 1-9 , the present invention provides a technical solution: a concrete filling device for processing prefabricated slabs, including a machine frame 100 and a pouring assembly 200 .

[0056] The pouring assembly 200 is installed on the frame 100, and the position of the frame 100 is moved through the frame 100 to drive the movement of the pouring assembly 200, and the prefabricated formwork of the reinforced concrete prefabricated plate is poured concrete through the pouring assembly 200.

[0057] see figure 1 , 2 3. The frame 100 includes a frame body 110 and a mobile vehicle body 120. It should be noted that the mobile vehicle body 120 is fixedly installed on both sides of the frame body 110, and is connected by bolts.

[0058] see figure 1 , 4 , 5, 6, 7, 8, 9, the pouring assembly 200 includes a linear guide rail 210, a hopper 220, a bracket 230, a sliding frame 240, an electric push rod 250 and a baffle plate 260. It should be noted that the linear gui...

Embodiment 3

[0060] see Figure 1-9 , the present invention provides a technical solution: a concrete filling device for processing prefabricated slabs, including a machine frame 100 and a pouring assembly 200 .

[0061] The pouring assembly 200 is installed on the frame 100, and the position of the frame 100 is moved through the frame 100 to drive the movement of the pouring assembly 200, and the prefabricated formwork of the reinforced concrete prefabricated plate is poured concrete through the pouring assembly 200.

[0062] see figure 1 , 2 3. The frame 100 includes a frame body 110 and a mobile vehicle body 120. It should be noted that the mobile vehicle body 120 is fixedly installed on both sides of the frame body 110 and is connected by bolts. In this embodiment, the mobile vehicle body 120 includes a first motor 121 and a rotating wheel 122. The first motor 121 is fixedly connected to the frame body 110 by means of bolt connection. The rotating wheel 122 is located below the frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com