Aerial pipeline arranging structure for horizontal numerical control rotary table

A CNC turntable and pipeline technology, which is used in metal processing equipment, metal processing mechanical parts, large fixed members, etc., can solve the problems of pipeline winding, many pipelines, twisting, etc., to achieve the overall compact optimization, the machine tool runs fast, and the The effect of pipe routing simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

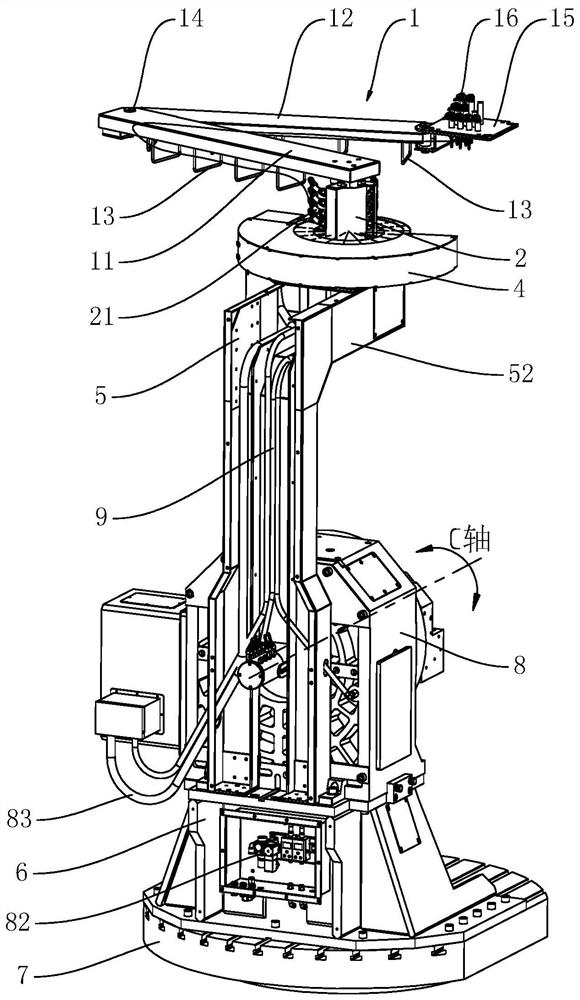

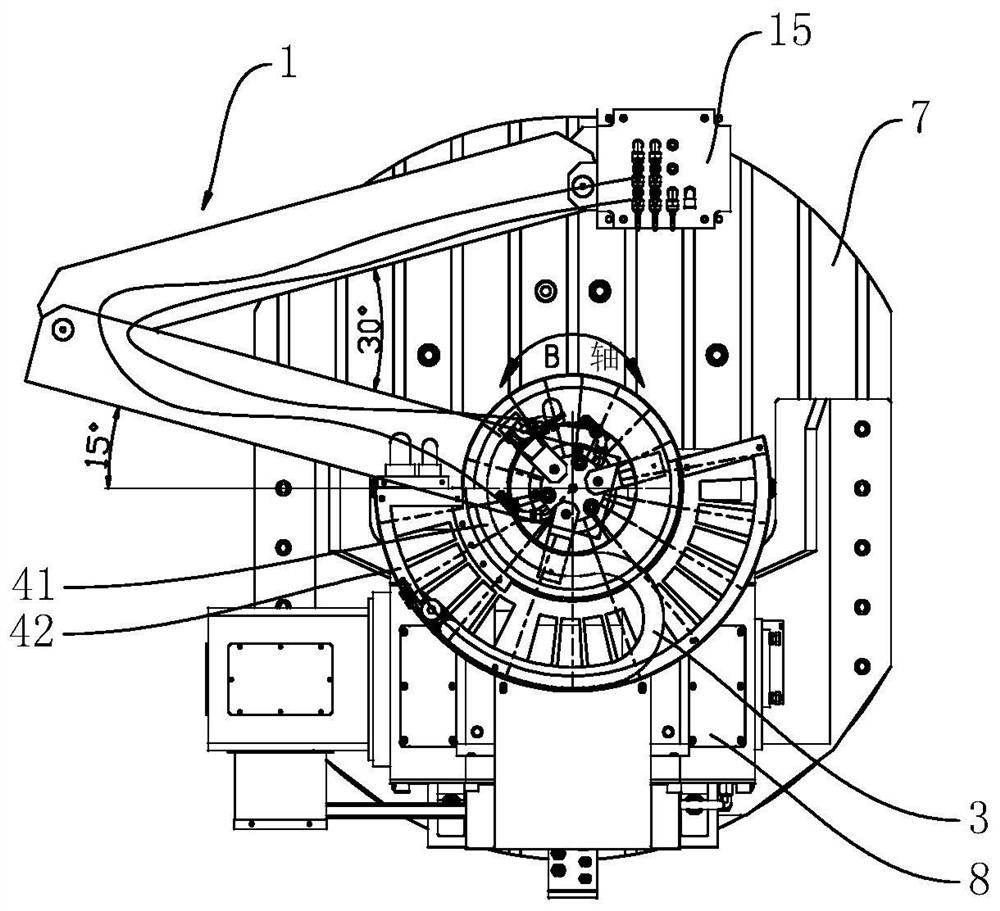

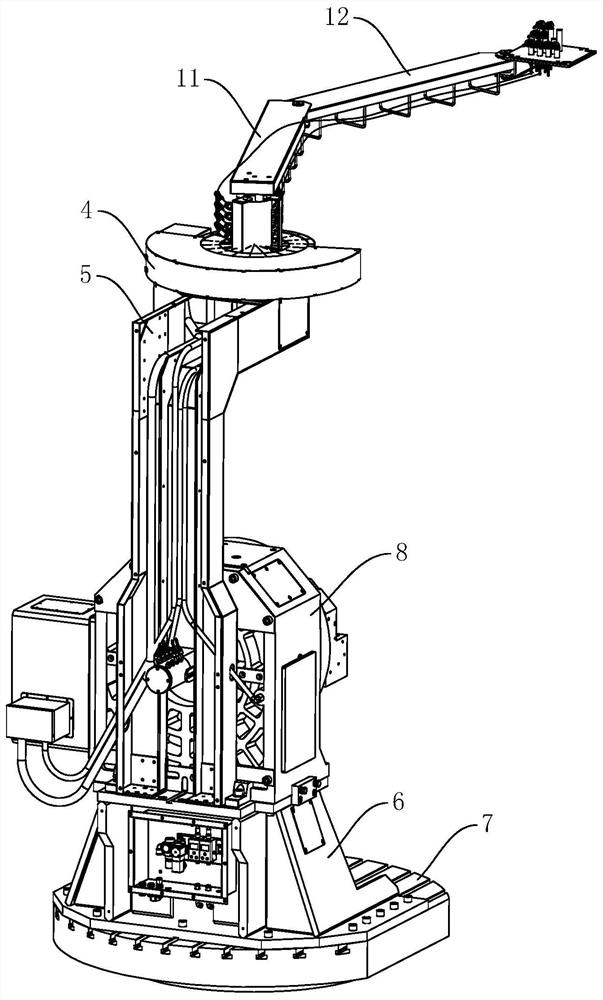

[0025] The aerial pipeline structure of the lying plus CNC turntable of the embodiment, such as Figure 1 to Figure 6 As shown, it includes connecting rod 1, rotating distributor 2, rotating towline 3, rotating towline trough 4, wiring trough support 5 and base 6, connecting rod 1 is a foldable connecting rod 1, and the lower side of connecting rod 1 A number of lifting lugs 13 are fixed for pipelines to pass through and hang. The rotating drag chain 3 is coaxially arranged directly above the workbench 7. The rotating drag chain 3 is bent and arranged in the rotating drag chain groove 4. The ends are respectively fixed in the rotary towline tank 4, and the rotation range of the rotary towline 3 is ±180°. In this embodiment, the rotary distributor 2 adopts the prior art, and the rotary distributor 2 is provided with several first pipe joints 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com