Workshop welding fume collecting and purifying treatment system

A technology of dust collection and purification treatment, applied in the field of air purification, can solve the problems of employees' physical and mental health, poor smoke exhaust effect, etc., and achieve the effect of ensuring physical health, keeping clean, and ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

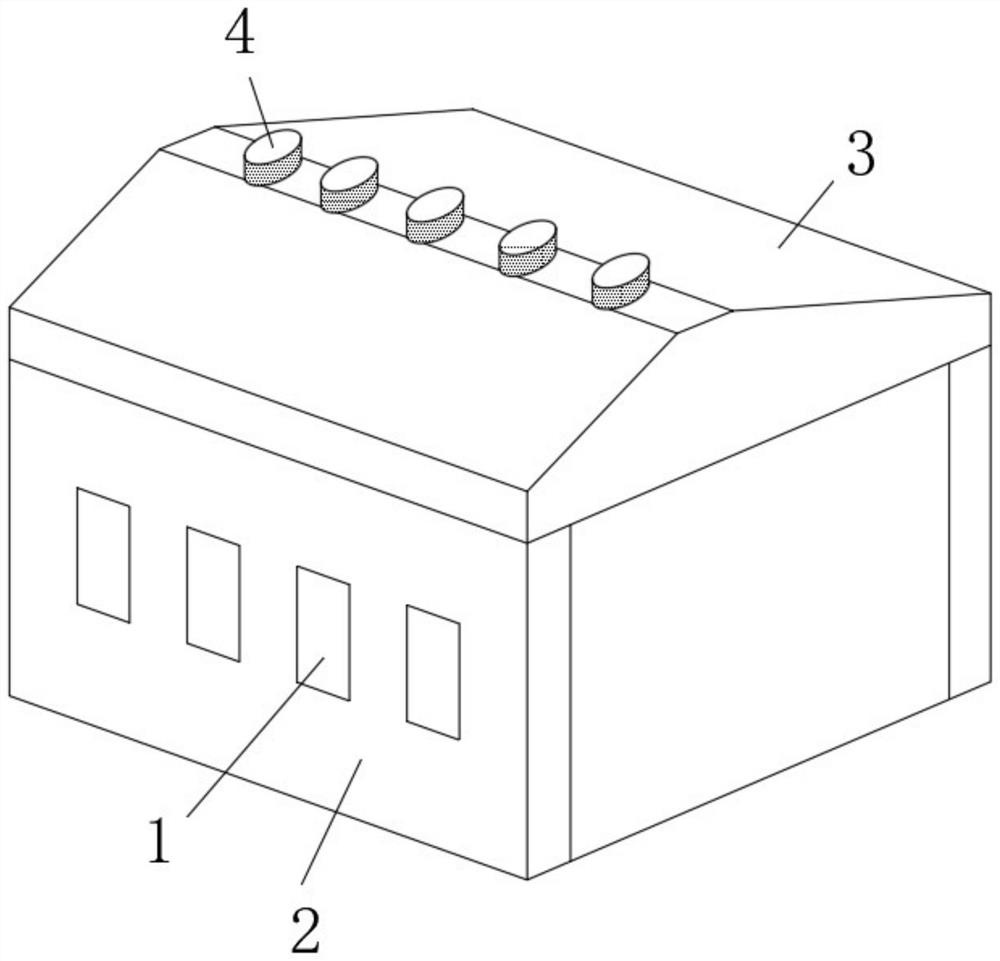

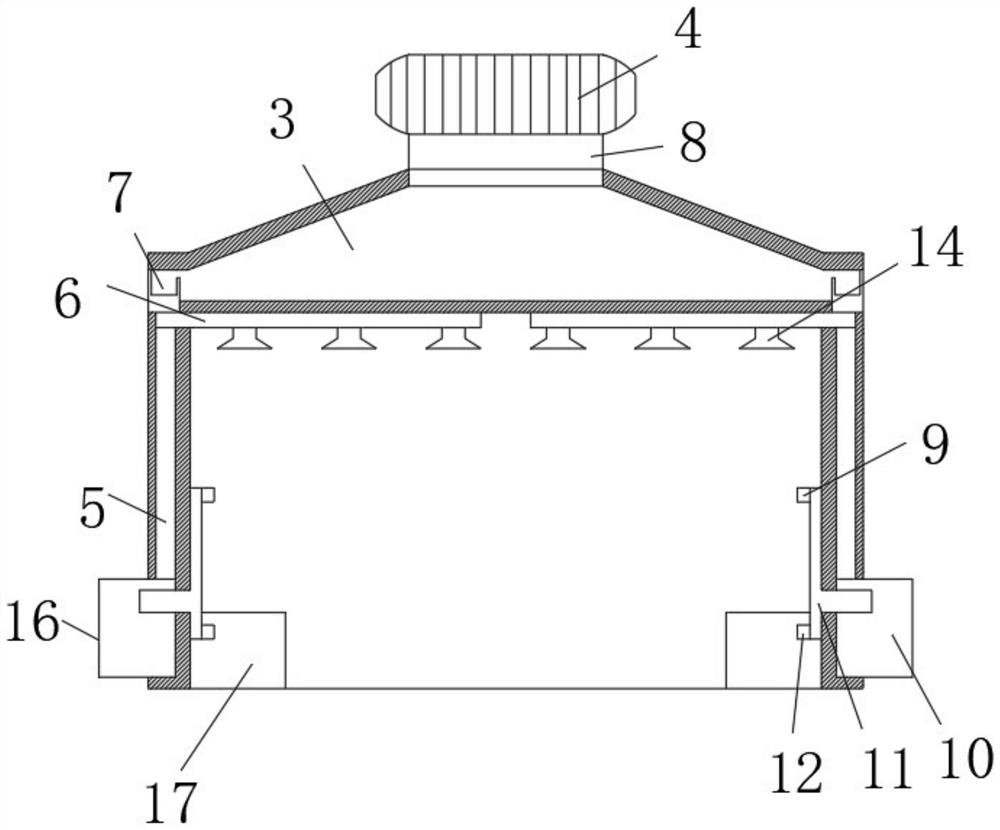

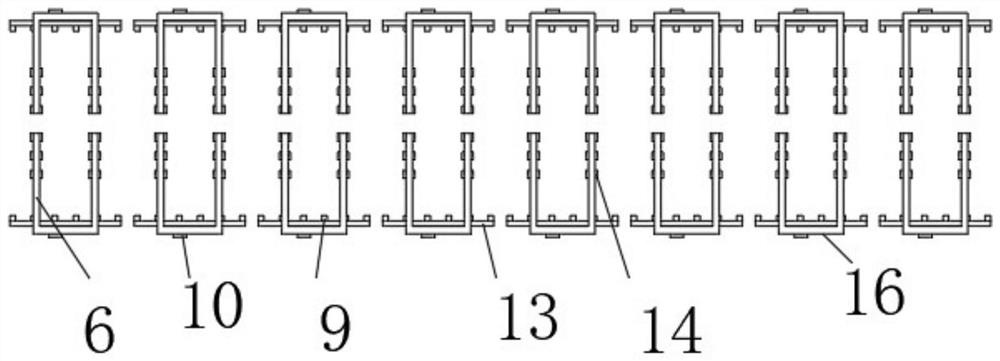

[0025] Such as Figure 1-4 As shown, the embodiment of the present invention provides a welding fume collection and purification treatment system in a workshop, including a factory building 2, the top of the factory building 2 is fixedly connected with a roof 3, and both sides of the inner wall of the factory building 2 are evenly distributed with soot treatment mechanisms 16. Mechanism 16 is opened or closed as required to ensure the purification and dissipation of smoke and dust in factory building 2. At the same time, the arrangement of rows of smoke and dust processing mechanisms 16 can also maximize the cleaning and purification of the air inside factory building 2. When smoke and dust processing mechanism 16 works At the same time, the ventilation fan 4 on the top of the roof 3 can discharge the air inside the factory building 2, and at the same time, the fresh air can be replaced in the factory building 2 through the fresh air duct 7. The lower parts of both sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com