A continuous filtration and reuse system for cutting fluid

A technology of cutting fluid and filtration membrane, applied in the field of continuous filtration and reuse of cutting fluid, can solve the problems affecting the filtration and reuse efficiency of cutting fluid, clogging of the filter screen, different utilization efficiency, etc., to achieve simple structure, efficient filtration, and use convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

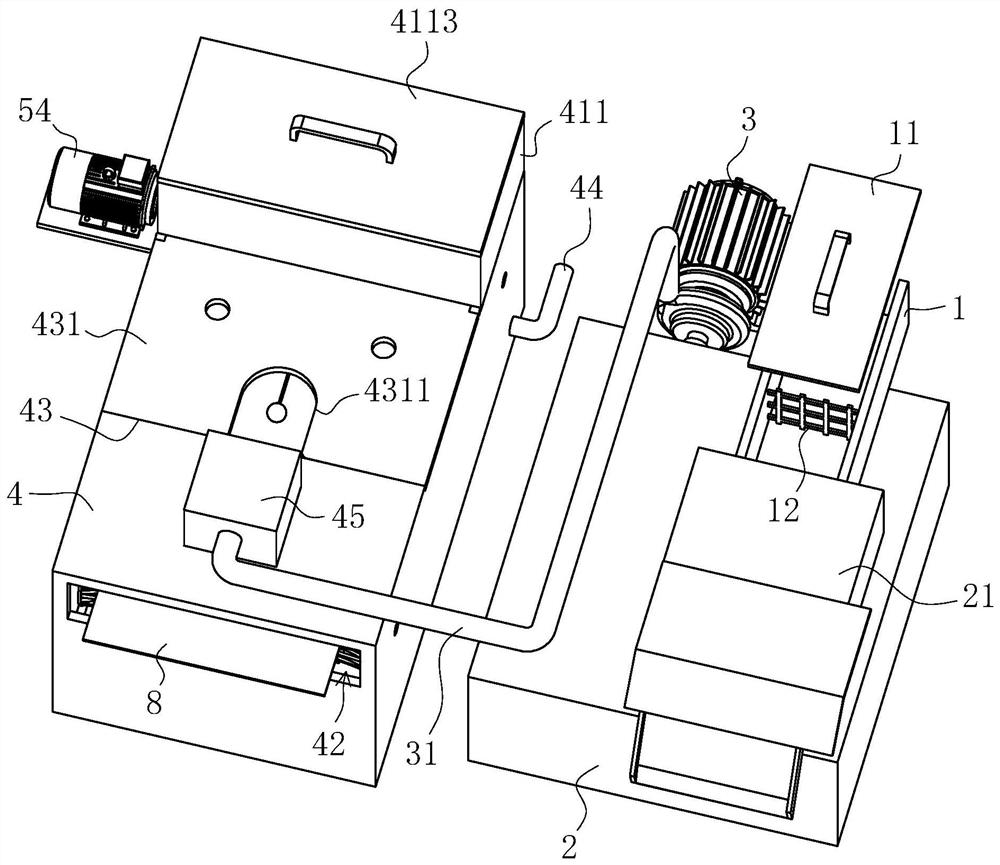

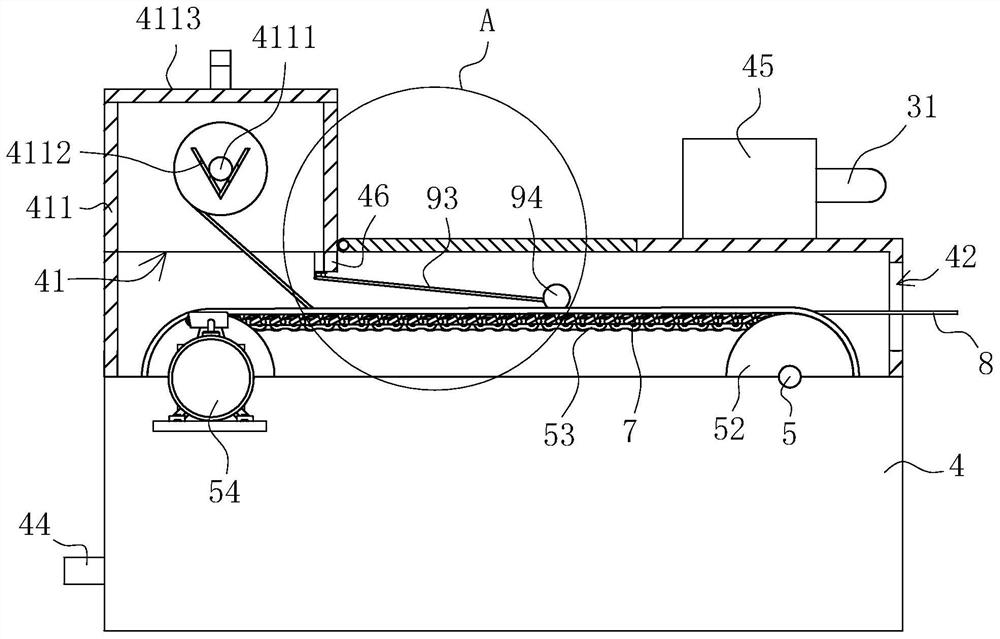

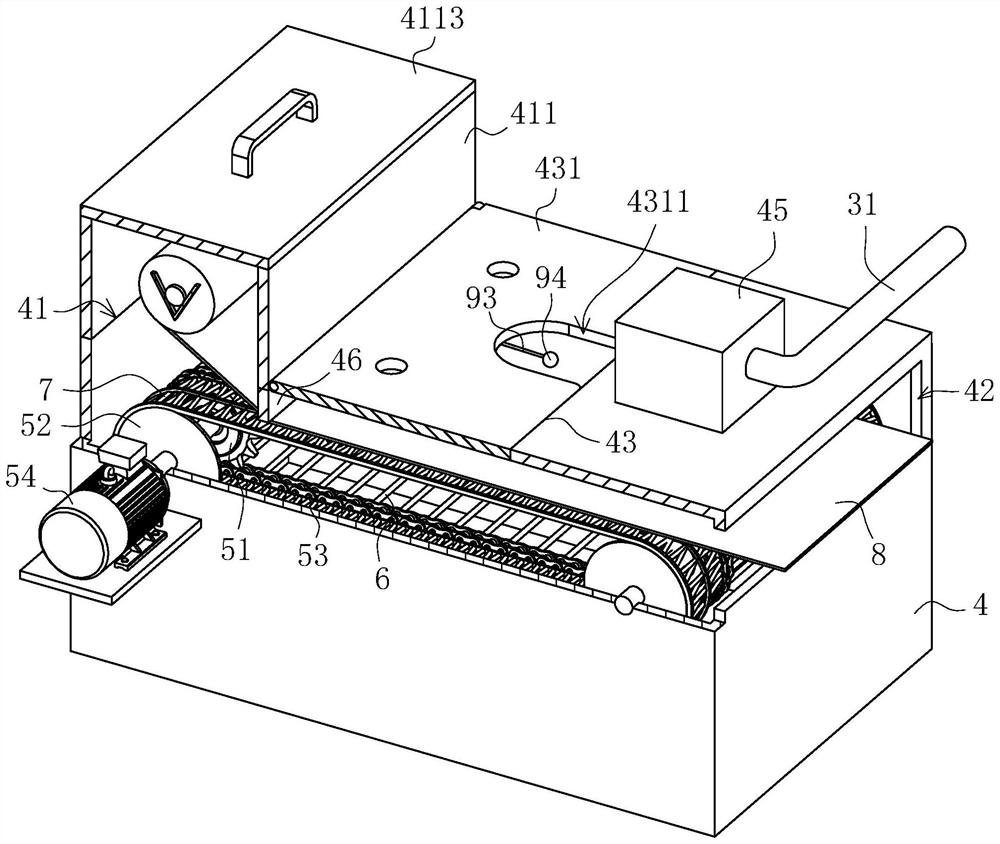

[0042] A cutting fluid continuous filtration recycling system, refer to figure 1 , which includes a liquid guide tank 1, a primary filter unit and a secondary filter unit connected in sequence. The primary filter unit includes a rectangular box-shaped collection box 2 , a magnetic adsorption mechanism 21 is arranged on the top of the collection box 2 , and the liquid guide tank 1 communicates with the magnetic adsorption mechanism 21 . The cutting fluid containing cutting chips generated during the machining process flows into the magnetic adsorption mechanism 21 through the liquid guide groove 1, and the large particles of iron debris are removed by magnetic adsorption through the magnetic adsorption mechanism 21, and the cutting fluid that initially removes the cutting chips flows into the collection Temporary storage in box 2. The magnetic adsorption mechanism 21 can be any commercially available magnetic separator. In this embodiment, it is a special magnetic separator fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com