Method for evaluating sorghum by peak gelatinization temperature

A technology of gelatinization temperature and sorghum, applied in the field of crop analysis, can solve the problems of quantitative evaluation, difficulty in popularization, and long time consumption, and achieve the effect of enriching the evaluation system, promoting industrial development, and improving the quality control ability of raw materials of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In this embodiment, red tassel sorghum is selected as the sample to be tested.

[0035] (1) Sorghum sample pretreatment

[0036] After removing impurities from the sorghum grains of the sample to be tested, 10 g of the sample to be tested was sampled by the quartering method, and further pulverized by a cyclone mill to pass through a 1 mm sieve. After fully mixing, take 5g of powder sample to measure the moisture content, then weigh 6-7mg of dry base sample into a special crucible for differential scanning calorimeter, add 14μL of ultrapure water, equilibrate at room temperature for 1h, and then use it to determine the gelatinization temperature.

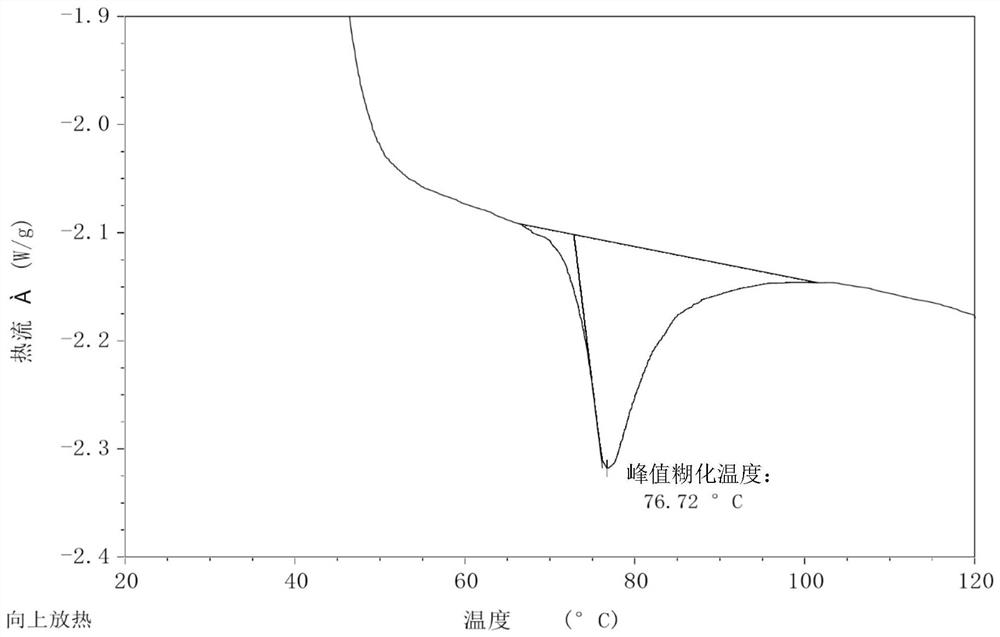

[0037] (2) Determination of peak gelatinization temperature

[0038] The peak gelatinization temperature of the sample was determined by differential scanning calorimetry, and the specific parameters were:

[0039] Nitrogen was used as a protective gas with a flow rate of 50 mL / min; the initial temperature was 40°C and kept...

Embodiment 2

[0043] In this embodiment, Australian sorghum is selected as the sample to be tested.

[0044] (1) Sorghum sample pretreatment

[0045] After removing impurities from the sorghum grains of the sample to be tested, 10 g of the sample to be tested was sampled by the quartering method, and further pulverized by a cyclone mill to pass through a 1 mm sieve. After fully mixing, take 5g of powder sample to measure the moisture content, then weigh 6-7mg of dry base sample into a special crucible for differential scanning calorimeter, add 14μL of ultrapure water, equilibrate at room temperature for 1h, and then use it to determine the gelatinization temperature.

[0046] (2) Determination of peak gelatinization temperature

[0047] The peak gelatinization temperature of the sample was determined by differential scanning calorimetry, and the specific parameters were:

[0048] Nitrogen was used as a protective gas with a flow rate of 50 mL / min; the initial temperature was 40°C and kept...

Embodiment 3

[0052] In this example, sorghum of Chuannuoliang No. 1 variety was selected as the sample to be tested.

[0053] (1) Sorghum sample pretreatment

[0054] After removing impurities from the sorghum grains of the sample to be tested, 10 g of the sample to be tested was sampled by the quartering method, and further pulverized by a cyclone mill to pass through a 1 mm sieve. After fully mixing, take 5g of powder sample to measure the moisture content, then weigh 6-7mg of dry base sample into a special crucible for differential scanning calorimeter, add 14μL of ultrapure water, equilibrate at room temperature for 1h, and then use it to determine the gelatinization temperature.

[0055] (2) Determination of peak gelatinization temperature

[0056] The peak gelatinization temperature of the sample was determined by differential scanning calorimetry, and the specific parameters were:

[0057] Nitrogen was used as a protective gas with a flow rate of 50 mL / min; the initial temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com