High-strength and light aluminum alloy door and window frame and preparation process thereof

A technology for aluminum alloy doors and windows and a preparation process, which is applied in the field of aluminum alloy profiles, can solve problems such as poor stability at the joints of door and window frames, and achieve the effects of avoiding poor stability, enhancing strength and improving assembly stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

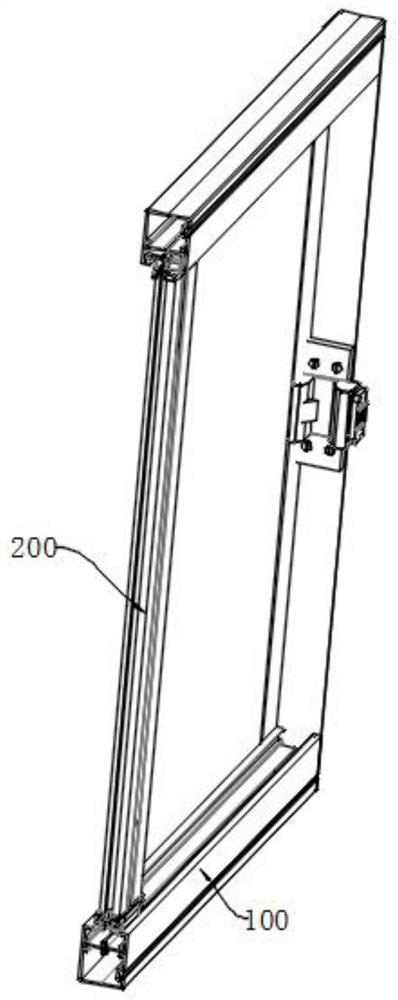

[0050] like figure 1 As shown, it is a schematic structural diagram of a high-strength, lightweight aluminum alloy door and window frame in a preferred embodiment of the present invention. The aluminum alloy doors and windows in this embodiment are mainly assembled and connected between the horizontal frame 100 and the vertical frame 200 in sequence. Formed, the horizontal frame 100 and the vertical frame 200 are all aluminum alloy profiles, which are convenient for assembly. The horizontal frame 100 and the vertical frame 200 realize quick disassembly and assembly, and improve production efficiency.

[0051] like figure 2 as well as image 3 As shown, the horizontal frame 100 is a hollow structure with an opening on one side, and an assembly groove 10 is arranged in the horizontal frame 100, and the assembly groove 10 is used to assemble the vertical frame 200. In this embodiment, the One end of the vertical frame 200 connected to the horizontal frame 100 is fixedly connec...

Embodiment 2

[0063] In this example, the components and preparation method of the high-temperature liquid aluminum alloy liquid in Example 1 are also provided, and the high-temperature industrial aluminum alloy includes the following components: by weight percentage:

[0064] Zn: 13.8%, Mg: 4.2%, Cu: 3.7%, Li: 2.1%, Si: 1.8%, and the balance is Al;

[0065] Raise the temperature of Al in the above materials to 700-800°C. At this time, the Al material is completely melted, and then add the remaining materials to the molten Al liquid, and raise the temperature to 900-1100°C. At this time, the high-temperature liquid aluminum alloy MgZn will be precipitated in the liquid 2 strengthening phase and CuAl 2 Strengthening phase, thereby improving the strength of the aluminum alloy material, the aluminum alloy material has higher strength after cooling and forming, and improves the material performance.

Embodiment 3

[0067] In this example, the components and preparation method of the high-temperature liquid aluminum alloy liquid in Example 1 are also provided, and the high-temperature industrial aluminum alloy includes the following components: by weight percentage:

[0068] Zn: 14.7%, Mg: 5.2%, Cu: 4.3%, Li: 2.8%, Si: 1.5%, and the balance is Al;

[0069] Raise the temperature of Al in the above materials to 700-800°C. At this time, the Al material is completely melted, and then add the remaining materials to the molten Al liquid, and raise the temperature to 900-1100°C. At this time, the high-temperature liquid aluminum alloy MgZn will be precipitated in the liquid 2 strengthening phase and CuAl 2 Strengthening phase, thereby improving the strength of the aluminum alloy material, the aluminum alloy material has higher strength after cooling and forming, and improves the material performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com