Oil-water separation and recovery device, floating oil separation method and application

A recovery device, oil-water separation technology, applied in the separation method, grease/oily substance/suspton removal device, liquid separation, etc., can solve threats to the marine ecological environment, exponential increase in cancer risk, and affect the separation efficiency of oil-water separation devices, etc. problems, to achieve the effects of wide working water area, performance improvement, and high oil-water separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

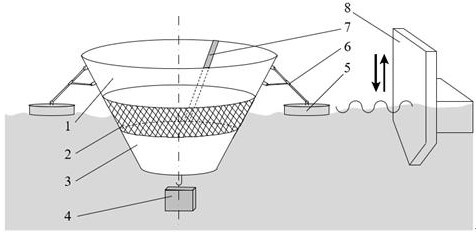

[0039] Such as figure 1 Shown, a kind of oil-water separation and recovery device, this surface oil separation and recovery device mainly comprises separation and collection container, balance floating body 5 and wave maker 8. The separation and collection container consists of an upper cylinder 1, a lower cylinder 3 and a wire mesh 2 connecting the upper and lower cylinders; the upper cylinder 1 and the lower cylinder 3 are made of stainless steel, and the shape is an inverted frustum of a cone; the upper cylinder 1, The lower cylinder body 3 and the wire mesh 2 are connected concentrically and welded to each other; the upper cylinder body 1 and the lower cylinder body 3 are connected by supporting steel bars 7 . The oil-water separation device floats on the water surface, and the gravity of the device must be balanced with the buoyancy it receives. As the device collects more floating oil, the device will slowly sink. Due to the characteristics of the oil-water separation d...

Embodiment 2

[0050] Preferably, as Figure 4 As shown, the nanostructure-modified wire mesh 2 can also be a micron coating material, metal foam.

[0051] Other parts of this embodiment are the same as the first embodiment.

Embodiment 3

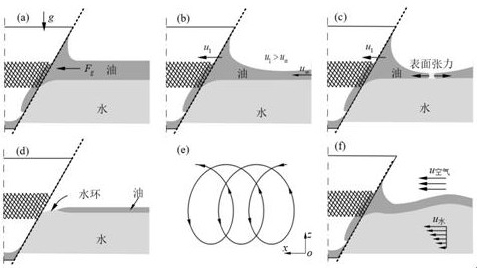

[0053] Such as Figure 5 As shown, when it is applied to a calm water surface, the wave maker 8 is turned on, and the box is oscillated to generate waves. The particle displacement on the water surface is greater than the wave displacement, so that the water ring cannot be formed stably, and the oil-water separation efficiency is over 94%.

[0054] Other parts of this embodiment are the same as those of the first and second embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com