Preparation method of cigarette paper tube with functional inner walls added in different areas and prepared cigarette paper tube

A cigarette paper and functional technology, applied in the field of heated cigarettes, can solve the problems of poor anti-seepage performance of paper tubes, uneven flavoring of smoke, and weak fragrance-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

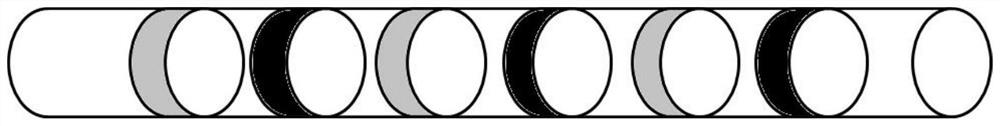

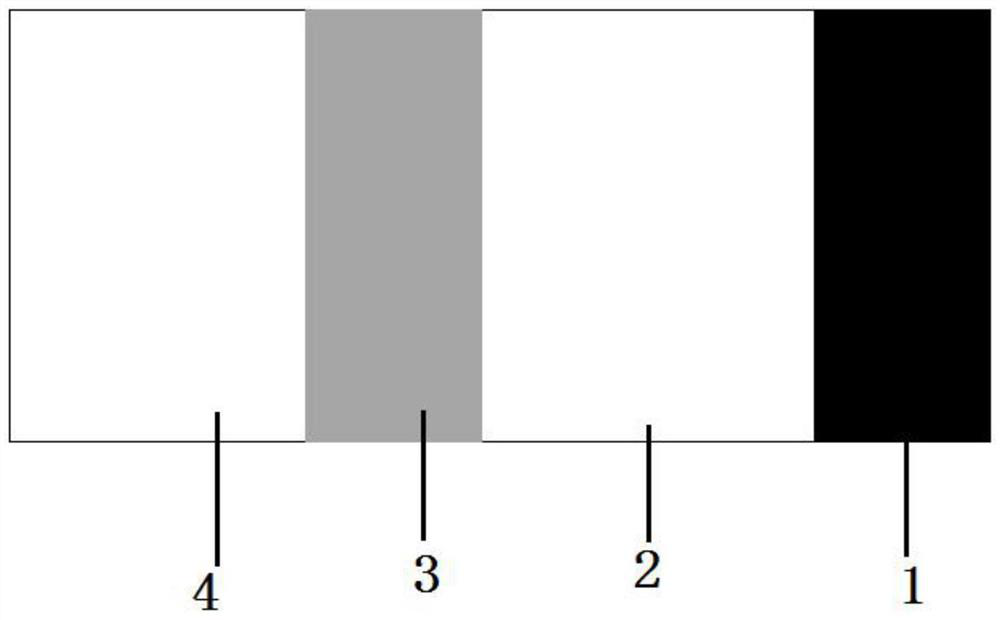

[0041] Such as figure 2 , this embodiment provides an embodiment of a cigarette paper tube with partitions and inner walls with different functions. The heating cigarette in this embodiment includes a smoking material section 1 , a supporting section 2 , a flavoring section 3 , and a filter section 4 .

[0042] According to different filling materials, in this embodiment, a waterproof layer and an oil-proof layer are coated on the inner wall of the smoking material section 1 of the cigarette paper tube (see figure 2 middle black part), the inner wall of flavoring section 3 is coated with essence and fragrance gel (see figure 2 gray part).

[0043] The waterproof layer is selected from alkyl ketene dimer AKD, and the oil-resistant layer is selected from fluorocarbon organic matter.

[0044] Concrete preparation method comprises the following steps:

[0045] (1) Take the cigarette paper tube rod in a flat form, and then add a functional layer to the inner wall of the cigar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com