Low-cost high-strength near-beta-Ti alloy and preparation method thereof

A high-strength, low-cost technology, used in metal processing equipment and other directions, can solve the problems of increasing cost, high cost, and restricting wide application, and achieve the effect of reducing economic cost, improving plasticity, and improving oxidation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

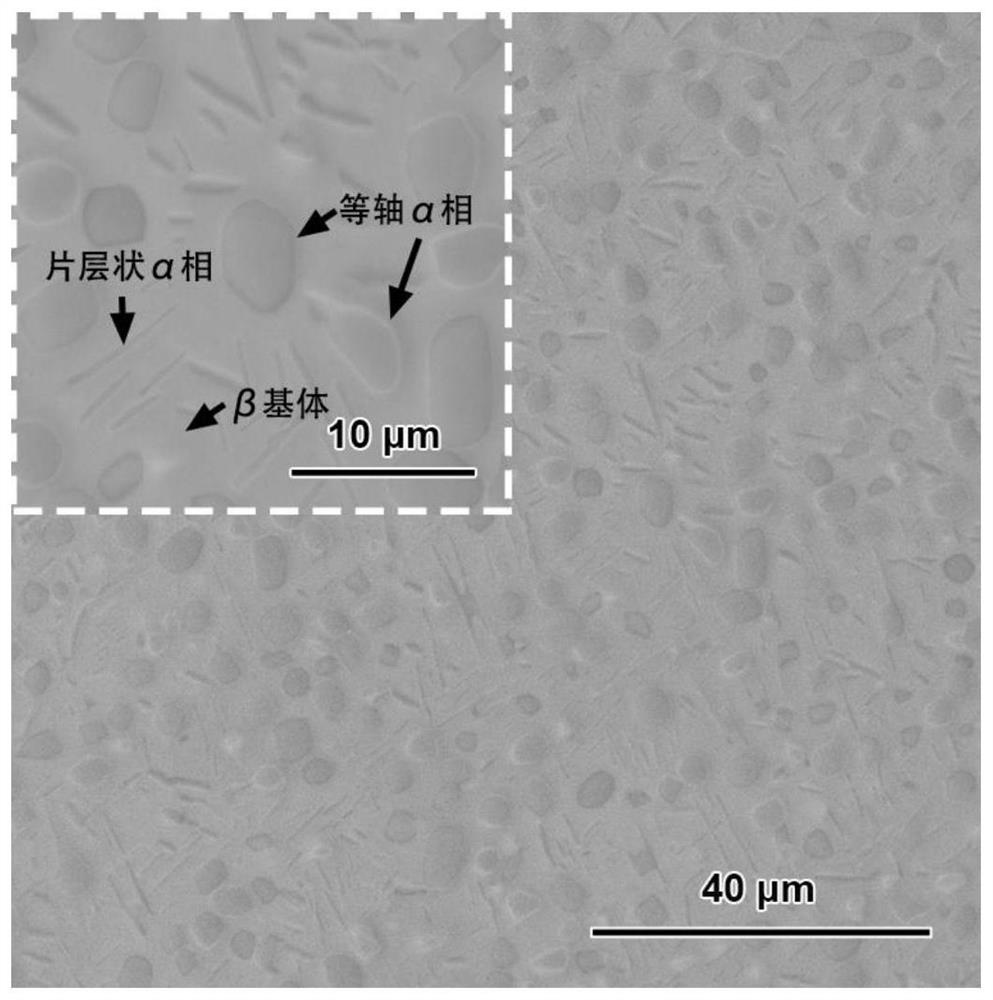

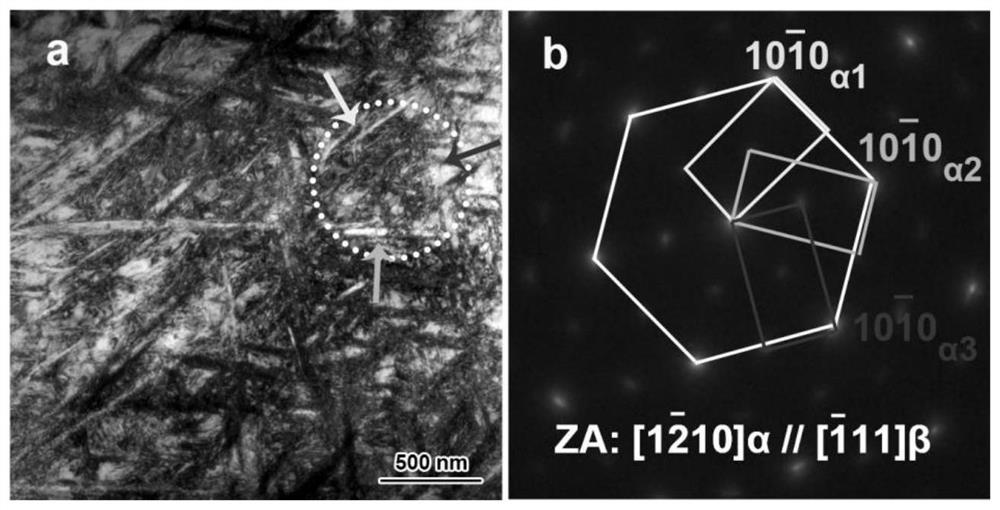

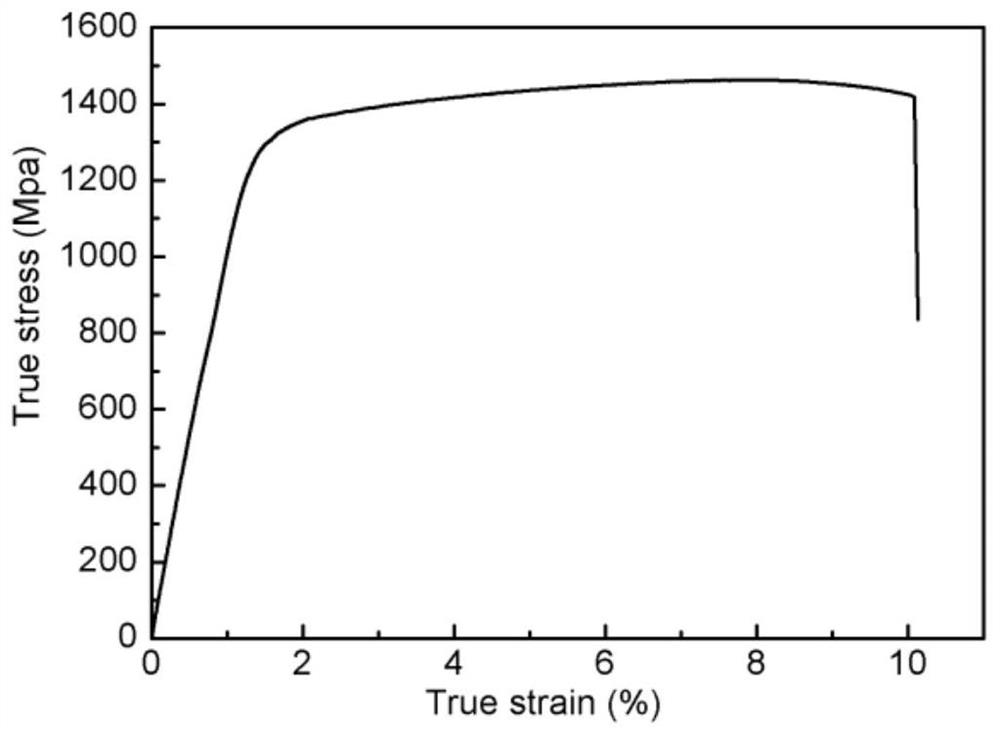

[0028] Embodiment 1: as figure 1 As shown, the present embodiment provides a low-cost high-strength near-β-Ti alloy, including Ti, Mo, Al, Cr, Fe, and a small amount of inevitable impurity elements such as O, C, and H; wherein, by mass percentage , the mass fractions of main elements Mo, Al, Cr, and Fe are 7.37%, 3.22%, 1.83%, and 1.36%, respectively, the mass fraction of impurity elements is 0.3%, and the balance is Ti. The forged alloy samples are first obtained through alloy casting and forging processes. The melting temperature is 2400-2600 °C, the number of remelting times for the ingot is 3-5 times, and the temperature of the billet β-phase zone opening section is 900-950 °C, two-phase The zone forging temperature is 700-750°C, and the number of double-phase zone forgings is 18 times. Then the forged alloy is subjected to solution treatment at a solution temperature of 750°C for 4 hours, and then aged at 500°C for 1 hour. . The obtained near β-Ti alloy has a tensile st...

Embodiment 2

[0029] Embodiment 2: This embodiment provides a low-cost high-strength near-β-Ti alloy, including Ti, Mo, Al, Cr, Fe, and a small amount of inevitable impurity elements such as O, C, and H; wherein, by mass percentage Calculated, the mass fractions of main elements Mo, Al, Cr, and Fe are 7.37%, 3.22%, 1.83%, and 1.36%, respectively, the mass fractions of impurity elements are 0.25%, and the balance is Ti. The forged alloy samples are firstly obtained through alloy casting and forging processes, the melting temperature is 2400-2600°C, the number of remelting of the ingot is 3-5 times, the temperature of the ingot β-phase zone opening section is 900-950°C, two-phase The forging temperature in the zone is 700-750°C, and the number of forgings in the dual-phase zone is 18 times. Then, the forged alloy is subjected to solution treatment at a solution temperature of 800° C. for 4 hours, and then aged at 500° C. for 2 hours. The tensile strength of the alloy is 1557MPa, the yield st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com