Brandy brewing method

A technology of brandy and grapes, which is applied in biochemical equipment and methods, wine preparation, alcoholic beverage preparation, etc., can solve the problems of few applications, and achieve the effects of strong aroma, increasing the number of base wines, and enriching styles and types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

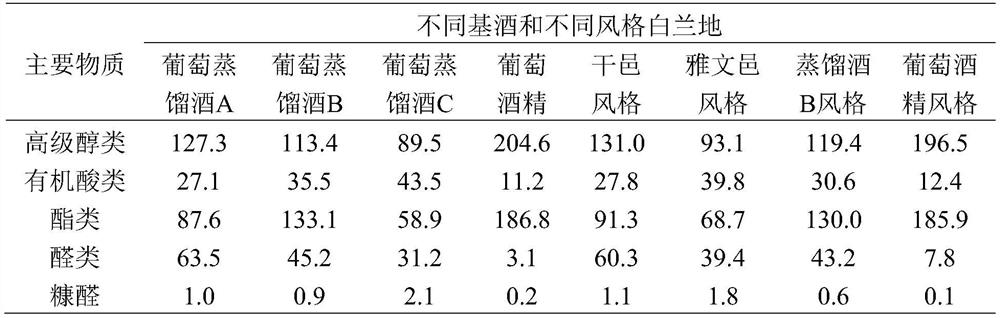

Image

Examples

Embodiment 1

[0036] A brandy brewing method specifically comprises the following steps:

[0037] 1. Preparation of base wine

[0038] S1. After the first distillation of the grape fermented raw wine by pot distillation, the obtained crude distillate is directly introduced into the distillation tower for tower distillation, and the obtained fraction is grape distilled wine B; wherein the crude distillate has an ethanol volume concentration of 30 %;

[0039] S2. Obtain grape distilled wine A after two discontinuous distillations of grape fermented original wine through pot distillation; the alcohol content of grape distilled wine A is 70% vol;

[0040] S3. Obtain grape distilled wine C after tower distillation of grape fermented raw wine; the alcohol content of grape distilled wine C is 52% vol;

[0041] S4. Treat the grape fermented raw wine through a professional directional reverse osmosis membrane system, separate alcohol, aromatic substances soluble in alcohols and esters from the res...

Embodiment 2

[0052] A brandy brewing method specifically comprises the following steps:

[0053] 1. Preparation of base wine

[0054] S1. After the first distillation of the grape fermented raw wine by pot distillation, the obtained crude distillate is directly introduced into the distillation tower for tower distillation, and the obtained fraction is grape distilled wine B; wherein the crude distillate has an ethanol volume concentration of 28 %;

[0055] S2. Obtain grape distilled wine A after two discontinuous distillations of the original wine fermented by pot distillation; the alcohol content of grape distilled wine A is 69% vol.

[0056] S3. Obtain grape distilled wine C after tower distillation of grape fermented raw wine; the alcohol content of grape distilled wine C is 50% vol;

[0057] S4. Treat the grape fermented raw wine through a professional directional reverse osmosis membrane system, separate alcohol, aromatic substances soluble in alcohols and esters from the rest of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com