Wheel-crawler dual-purpose multifunctional belt opening machine

A multi-functional, belt-opening machine technology, applied to tracked vehicles, motor vehicles, earth movers/excavators, etc., can solve the problems of inconvenience, damage to the transmission system, and limited space in the lower part, and achieve high efficiency and off-road performance Good, the effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below with reference to the drawings and embodiments.

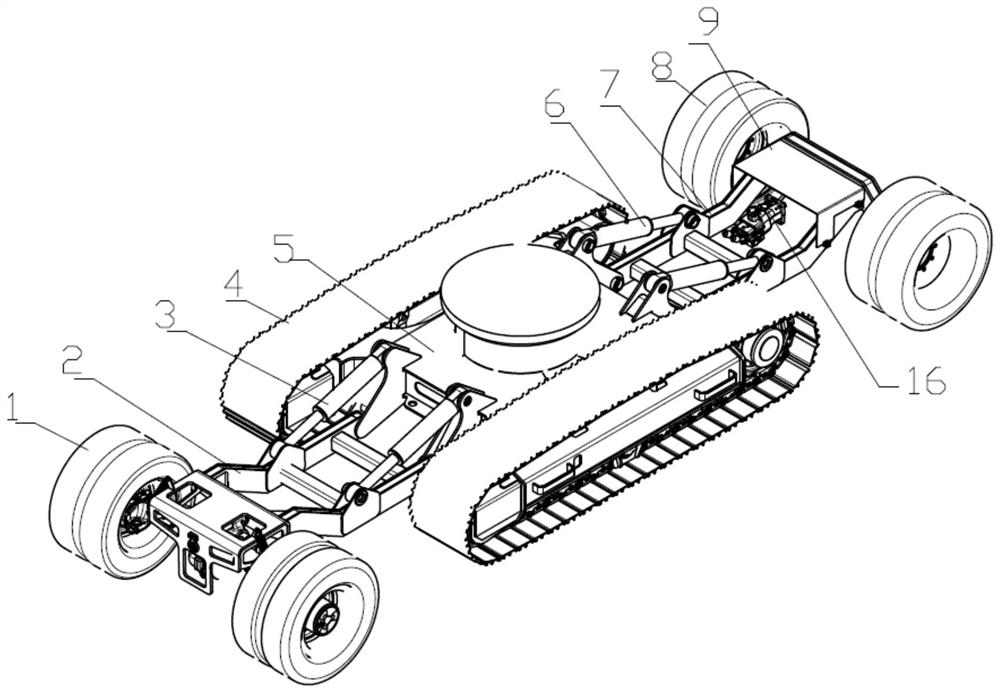

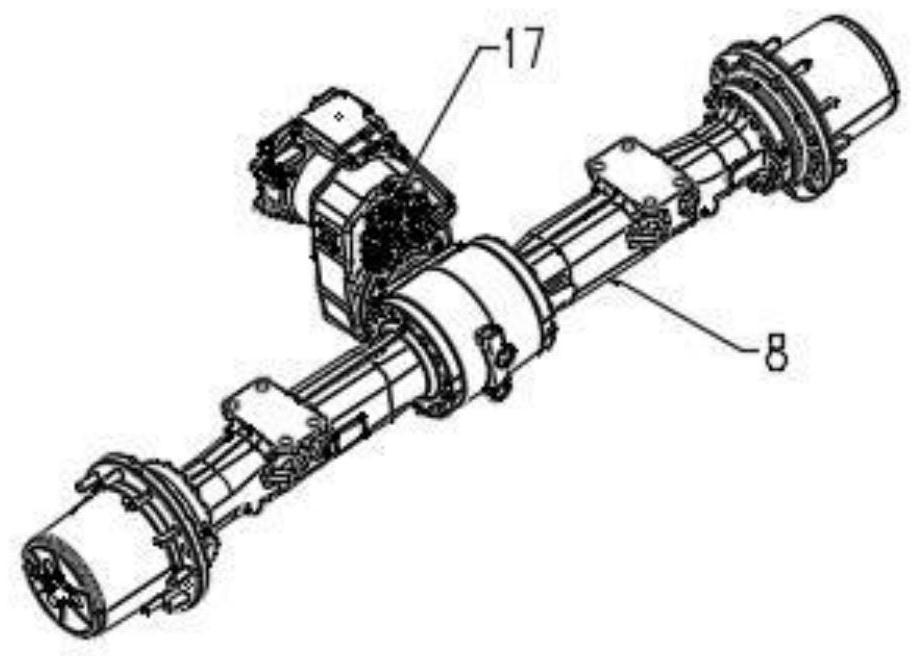

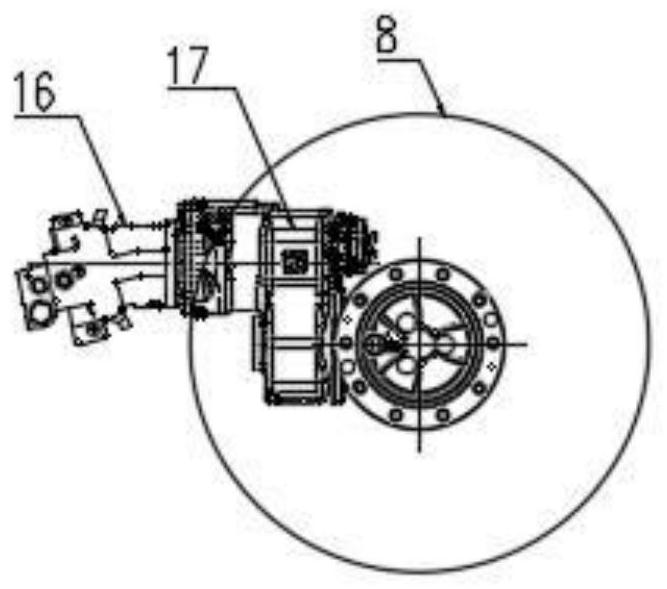

[0033] Such as Figure 1-10 As shown, the wheel-track dual-purpose multi-functional unwinding machine of the present embodiment includes a vehicle frame 5, a crawler chassis 4 and a wheeled traveling mechanism, and the crawler chassis 4 adopts hydraulic drive and control; the wheeled traveling mechanism Including front axle assembly 1, front axle support 2, front axle push-pull cylinder 3, rear axle assembly 8, rear axle support 7 and rear axle push-pull cylinder 6, the front axle assembly 1 passes through front axle support 2 and vehicle frame 5 is assembled and driven up or down by the front axle push-pull cylinder 3, and the rear axle assembly 8 is assembled with the vehicle frame by the rear axle support 7 and driven by the rear axle push-pull cylinder 6 to lift or descend.

[0034] Specifically, as figure 1 As shown, the front axle support 2 is hinged with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com