Efficient desulfurization activated carbon preparation system

A technology of activated carbon preparation and preparation system, which is applied in the field of high-efficiency desulfurization activated carbon preparation system, can solve the problems of damage to the pulverizer, inability to handle iron filings, affecting the pulverizing efficiency of the pulverizer, and achieve the effect of increasing the contact area and improving the adsorption efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

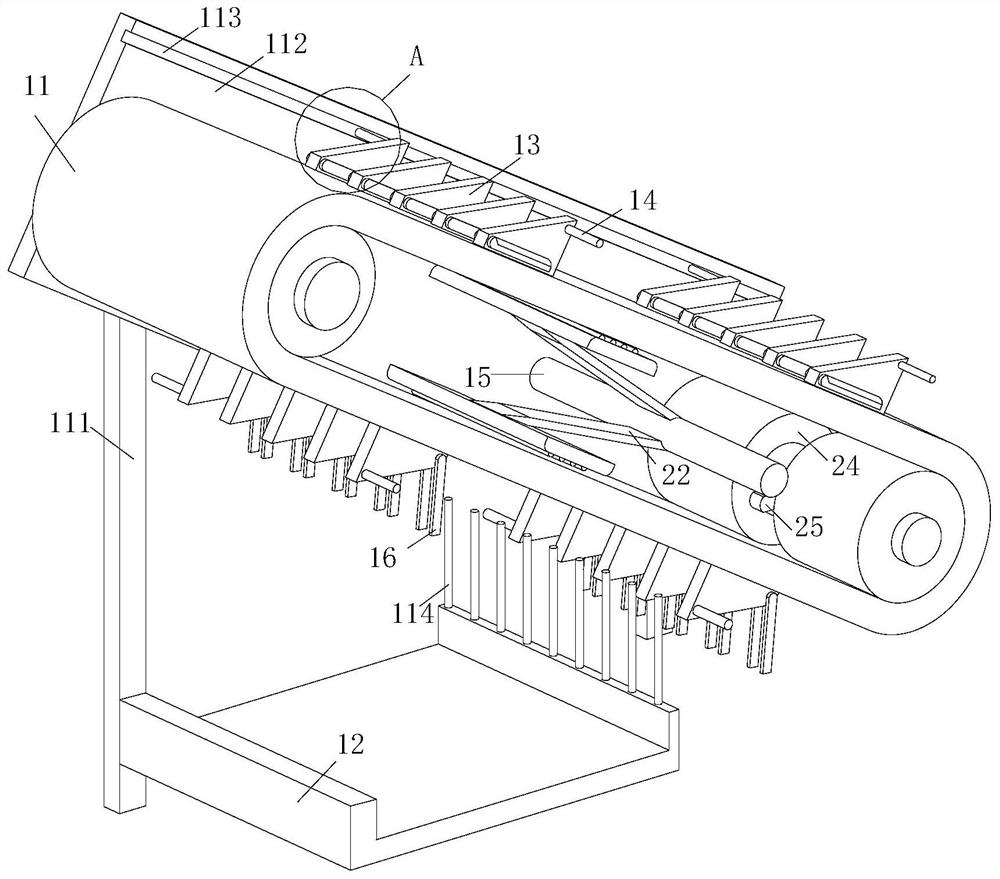

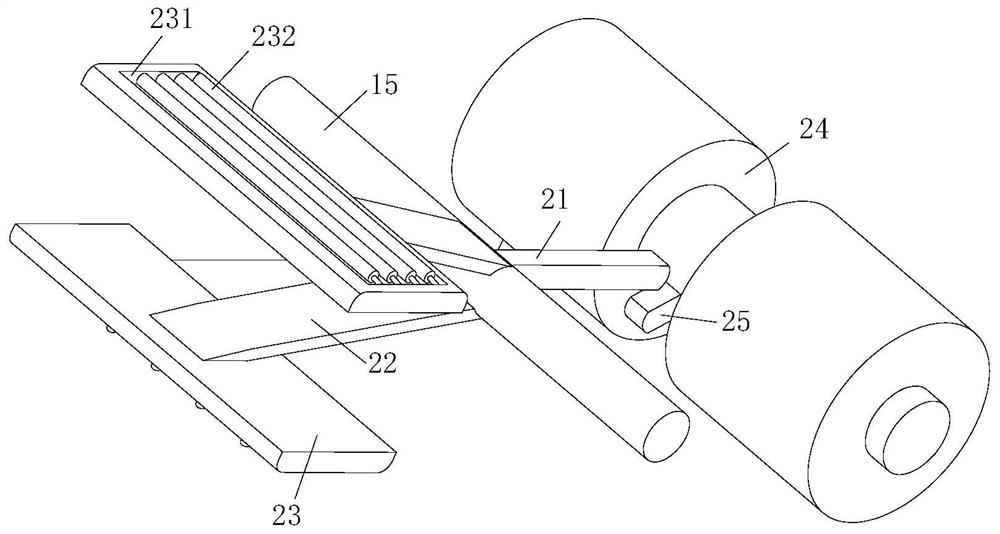

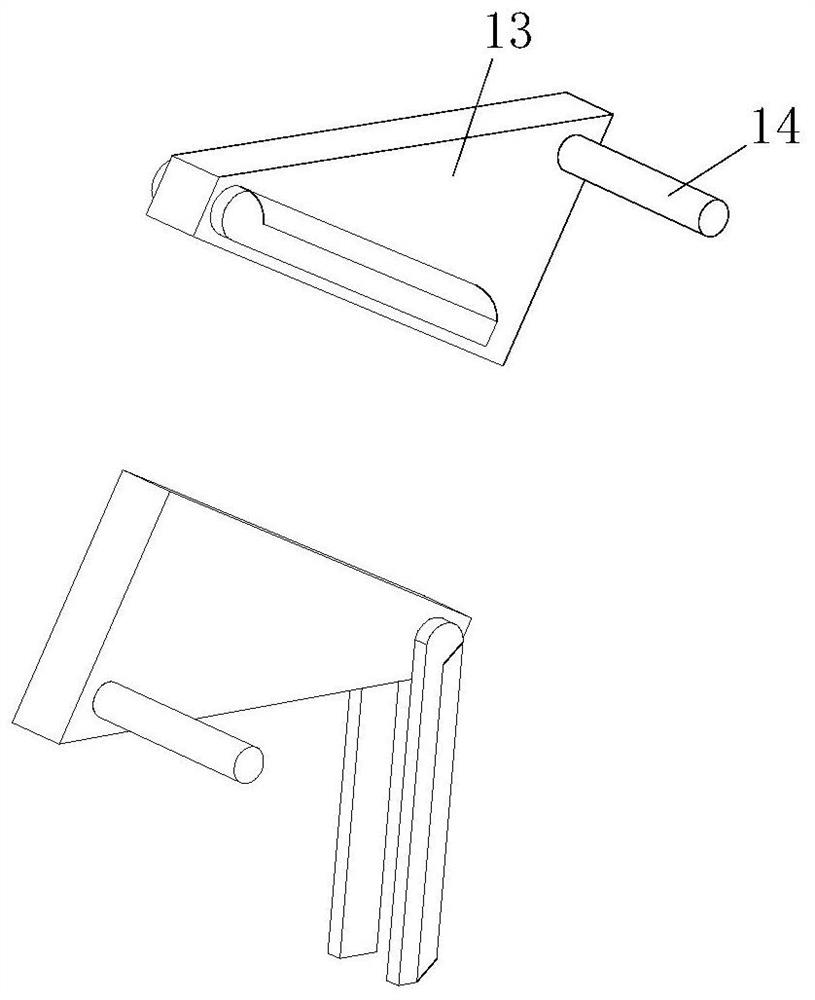

[0035] As a specific embodiment of the present invention, one end of the collecting plate 12 close to the middle of the conveyor belt 11 is fixedly connected with a brush 114, the brush 114 extends upward, and the brush 114 is in contact with the lower end surface of the conveyor belt 11;

[0036] During use, by connecting the brush 114 at the end of the collection plate 12 near the middle of the conveyor belt 11, and making the brush 114 extend upwards and contact the lower end surface of the conveyor belt 11, the motor rotates, and the conveyor belt 11 rotates with the motor, and the electromagnet 13 As the conveyor belt 11 rotates, when the electromagnet 13 moves to the lower end of the conveyor belt 11, the conductive column 14 on the electromagnet 13 breaks away from the No. Under the action of gravity, the iron filings fall off from the electromagnet 13 onto the collecting plate 12, thereby improving the subsequent adsorption efficiency of the electromagnet 13; The iron 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com