A material crushing particle size control system and its control method and application

A particle size control and particle size technology, applied in application, particle size analysis, particle and sedimentation analysis, etc., can solve the problem of uneven material particle size, achieve the effect of ensuring continuity, ensuring particle size consistency, and reducing the number of sampling operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

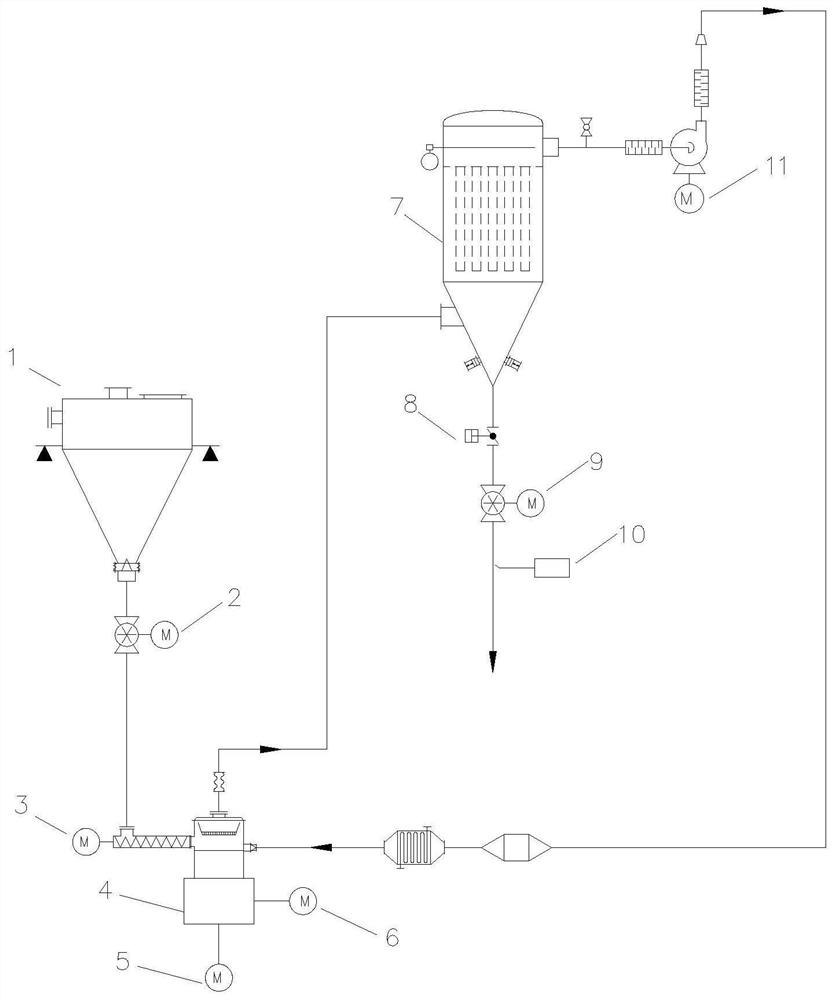

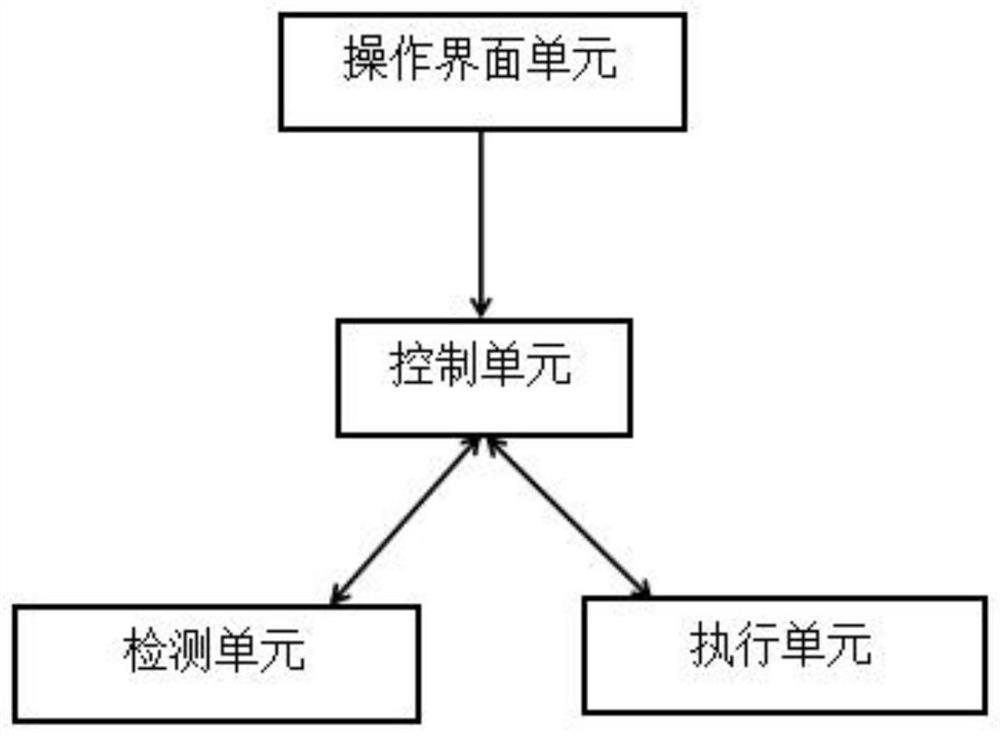

[0044] A material crushing particle size control system, such as figure 2 Shown includes:

[0045] The operation interface unit is used to input the setting parameters about the particle size of the pulverized material, the setting parameters include: particle size target value, particle size allowable error, sampling period, continuous particle size exceeding allowable times, particle size continuous normal setting times;

[0046] The detection unit is used for periodic sampling, and obtains the particle size measurement value and records the actual parameters of the number of particle size data and the sampling times;

[0047] a control unit, which is electrically connected to the operation interface unit and the detection unit, and is used to perform intelligent calculation and judgment on the actual parameter and the set parameter, and control the operation of the execution unit and the detection unit according to the calculation and judgment result;

[0048] The executi...

Embodiment 2

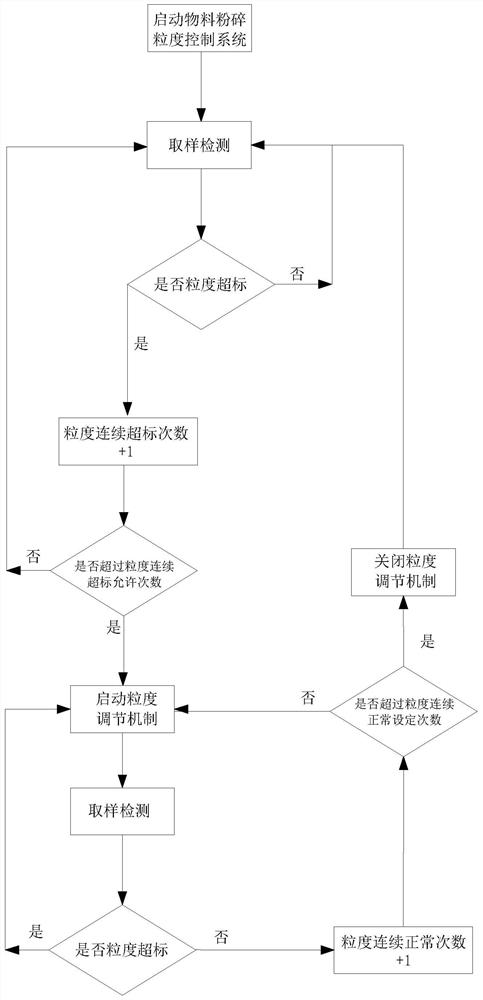

[0054] An operation method for controlling the pulverized particle size of the positive electrode material of a lithium battery in the application of the material pulverization particle size control system described in Example 1 in the production of the positive electrode material of the lithium battery.

[0055] First, enter the setting parameters in the operation interface unit of the material crushing particle size control system, including: the allowable times of continuous particle size exceeding the standard is 3, the normal setting times of continuous particle size is 3, the particle size target value is 15μm, the particle size allowable error is 1μm, and the normal sampling period It is 5 minutes / time, the abnormal sampling period (the abnormal sampling period is two gears, the sampling period of the first gear is 3 minutes / time, and the sampling period of the second gear is 1 minute / time), as well as the induced draft fan, grading wheel And the working frequency parame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com