Connector assembly

A technology of connector components and connector modules, which is applied in the direction of connections, components of connection devices, two-part connection devices, etc., can solve problems affecting the normal use of products, affecting product appearance and quality, poor waterproof performance of connector components, etc. , to achieve the effect of improving appearance and quality, and good waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to facilitate a better understanding of the purpose, structure, features and functions of the present invention, the connector assembly 100 of the present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

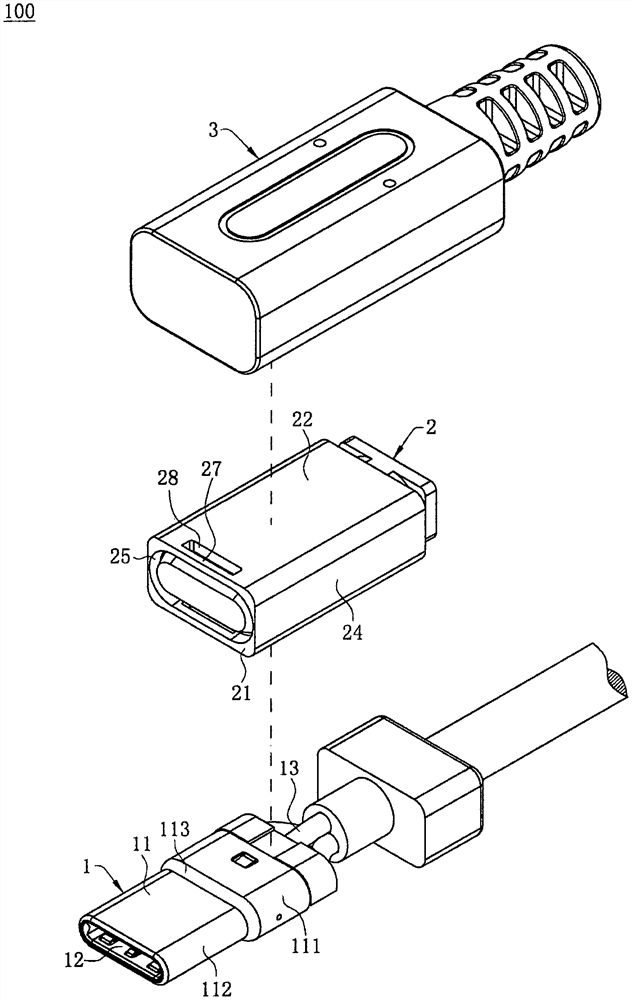

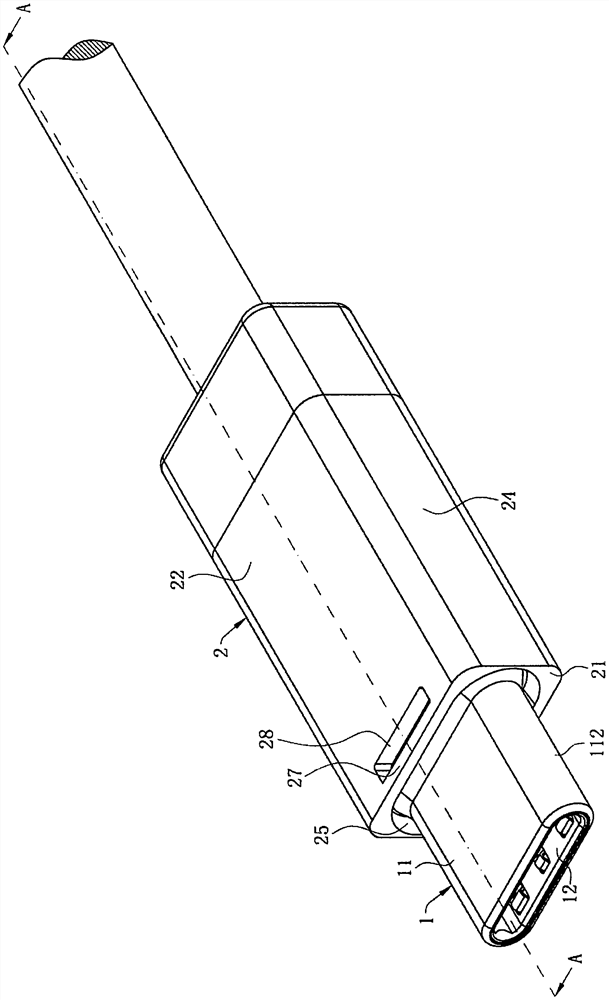

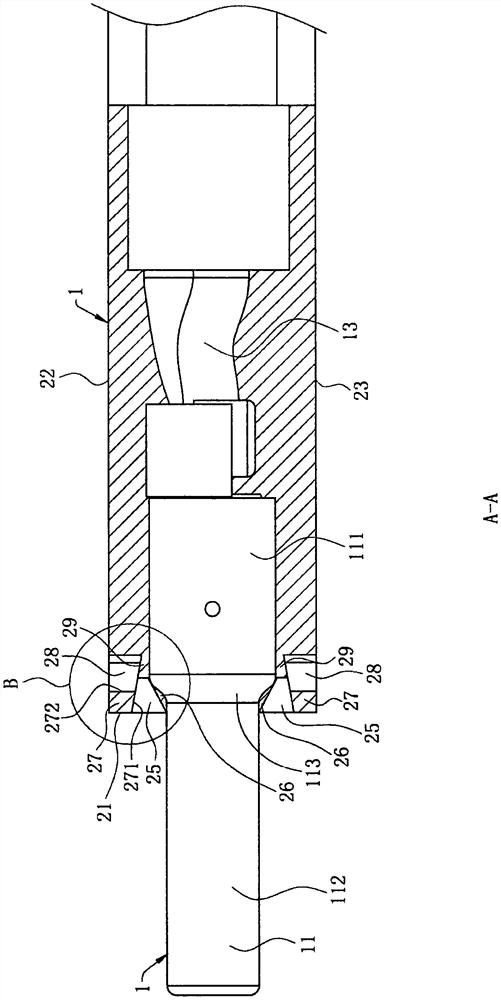

[0030] Such as figure 1 As shown, it is an exploded perspective view of the inventive connector assembly 100 , the connector assembly 100 includes a connector module 1 , a first shell 2 and a second shell 3 . In this embodiment, the connector module 1 includes an insulating body 12, a plurality of terminals (not shown, the same below), a metal shell 11 and a cable 13, and a plurality of the terminals are fixed on the The insulating body 12 is electrically connected to the cable 13 . The insulating body 12 is accommodated in the metal shell 11, and the metal shell 11 includes a base 111 and a pair of docking parts 112 extending from the base 111 for docking with a mating connector (not shown). The ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com