Piezoelectric wafer active sensor packaging structure

A piezoelectric chip and packaging structure technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve the problem of large environmental factors and waiting time Long, piezoelectric chip active sensor damage and other issues, to speed up installation efficiency and improve durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

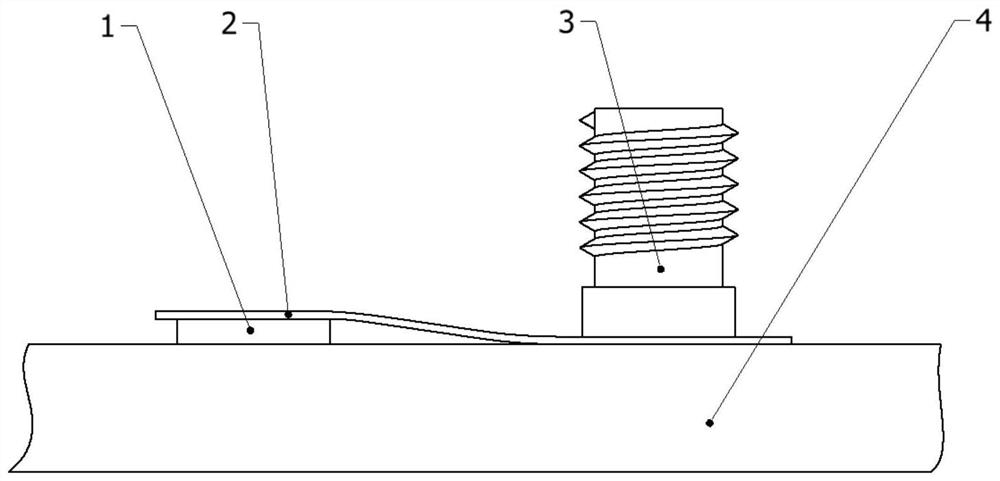

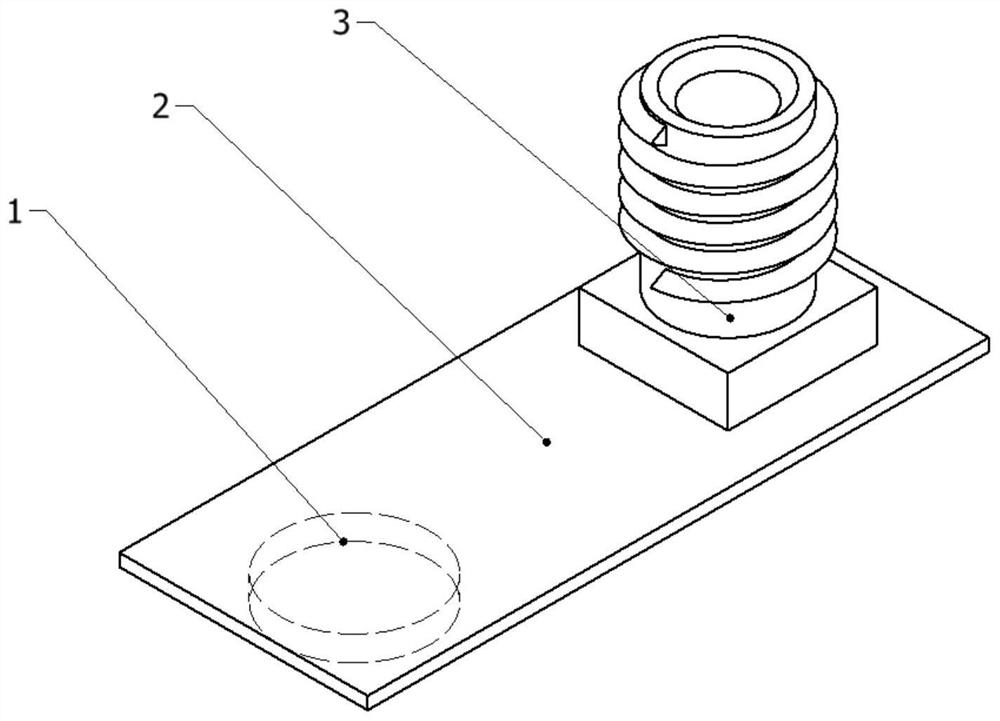

[0025] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

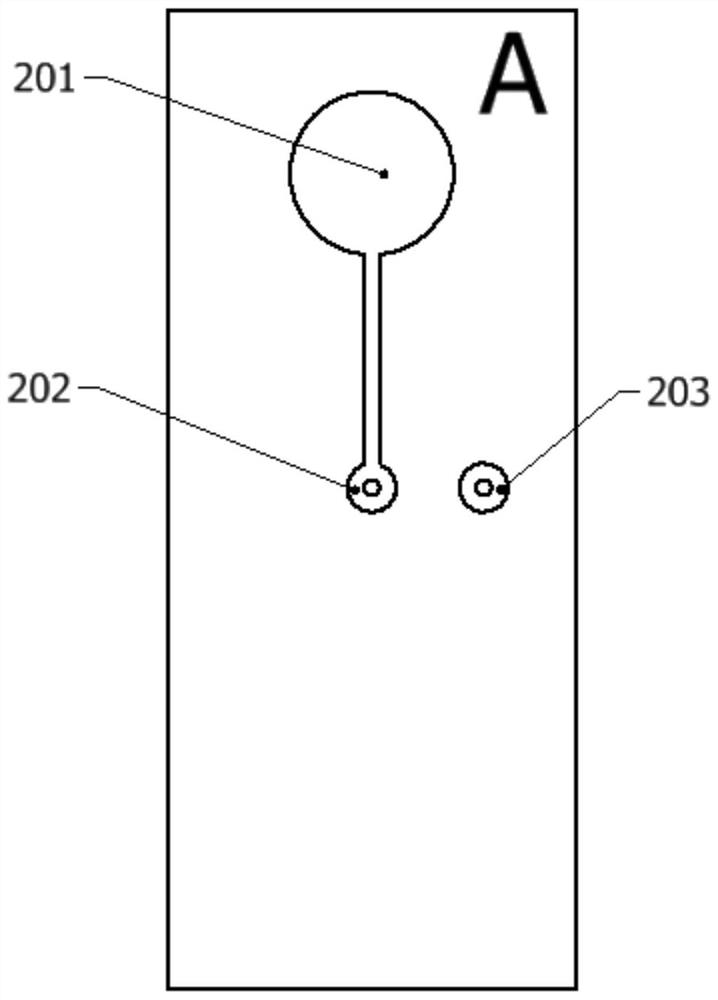

[0026] The present invention utilizes a flexible printed circuit (Flexible Printed Circuit, FPC), which uses an insulating flexible film 208 as a base material, forms a metal layer on both surfaces of the flexible film by electroplating or deposition, and makes printed circuits A210 and A210 respectively. Printed Circuits B211. The thickness of the flexible circuit board 2 is less than 0.15mm. The invention includes a flexible circuit board 2 with a printed circuit, a piezoelectric chip active sensor 1 and a radio frequency coaxial adapter 3 .

[0027] A packaging method and packaging structure of a piezoelectric wafer active sensor of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0028] refer to image 3 , Figure 4 Different printed ci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com