Gas sensitive material, preparation method and application thereof, and gas sensitive sensor element

A technology of gas-sensitive materials and cubes, which is applied in the direction of analyzing materials, material resistance, and material analysis by electromagnetic means.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

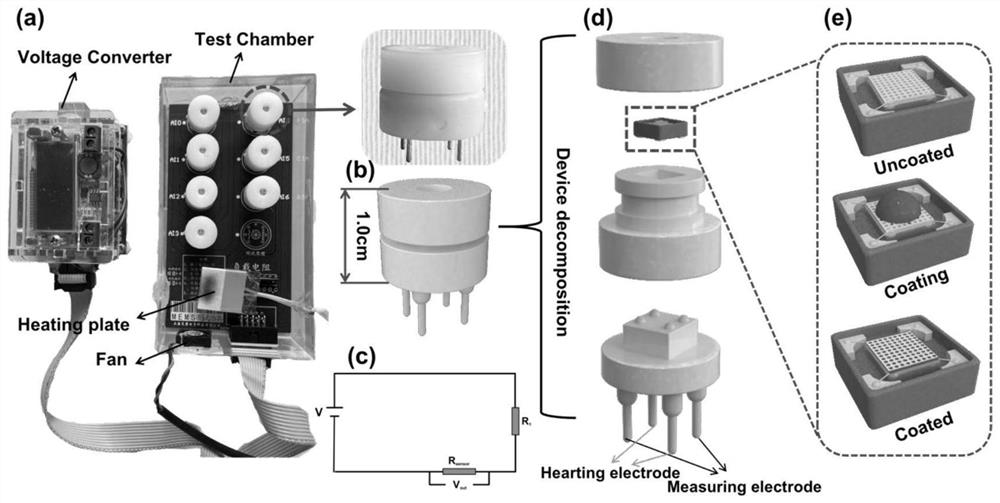

[0045] The present invention also provides a method for preparing the gas-sensitive material described in the above technical solution, comprising the following steps:

[0046] After mixing polyvinylpyrrolidone, potassium ferrocyanide and hydrochloric acid solution, carry out hydrothermal reaction to obtain Prussian blue;

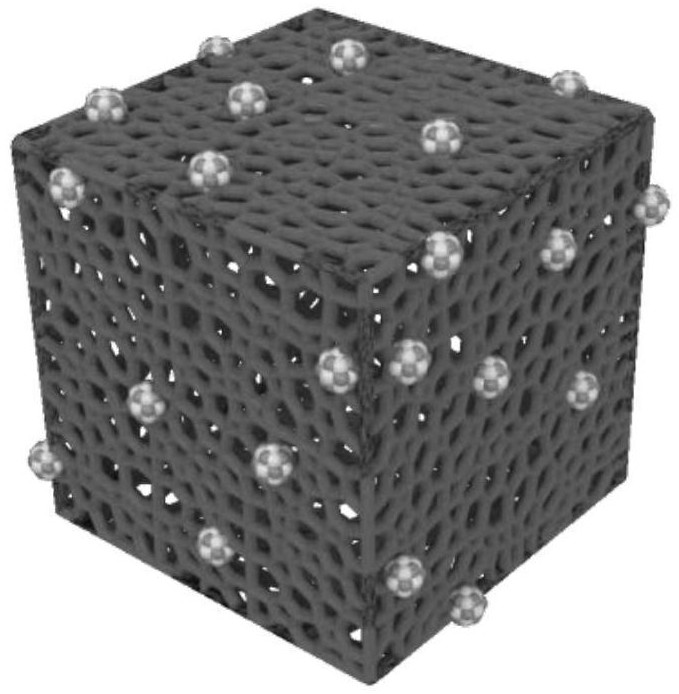

[0047] After mixing the Prussian blue and ethanol, the obtained Prussian blue suspension and sodium hydroxide solution are mixed, and a precipitation reaction is carried out to obtain iron hydroxide with a hollow cubic structure;

[0048] Carrying out the first calcination of the iron hydroxide with the hollow structure to obtain the Fe hydroxide with the hollow cubic structure 2 o 3 ;

[0049] After mixing the reducing agent, chloroauric acid and chloroplatinic acid, a reduction reaction is carried out to obtain an AuPt alloy;

[0050] The Fe of the hollow cubic structure 2 o 3 , AuPt alloy and ethanol are mixed and ultrasonicated to obtain the precur...

Embodiment 1

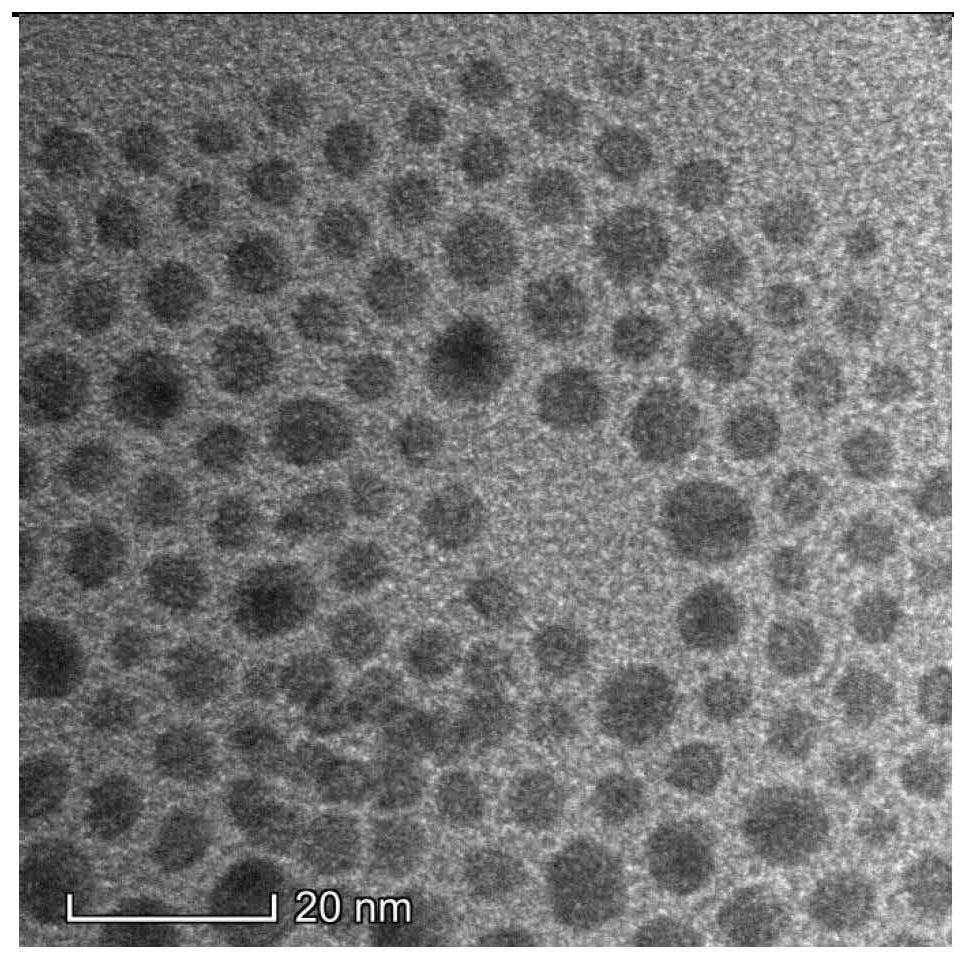

[0104] Add 3.8g of polyvinylpyrrolidone and 0.11g of potassium ferrocyanide to 50mL of 0.1mol / L hydrochloric acid solution, stir for 30 minutes, then conduct a hydrothermal reaction at 80°C for 24h, cool to room temperature, and centrifuge , to get Prussian blue;

[0105] 15 mg of the Prussian blue was washed several times with deionized water and absolute ethanol in turn, and mixed with 20 mL of absolute ethanol to obtain a Prussian blue suspension;

[0106] Take 10mL of the Prussian blue suspension and mix it with 17mL 0.02mol / L sodium hydroxide solution, rotate and shake for 20 minutes, after centrifugation, wash with deionized water and absolute ethanol several times successively to obtain ferric hydroxide with a hollow cubic structure;

[0107] Calcining the ferric hydroxide with the hollow cubic structure at 300°C for 6 hours with a heating rate of 0.5°C / min to obtain the Fe hydroxide with the hollow cubic structure 2 o 3 ;

[0108] Heat 10mL oleylamine to 110°C, stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com