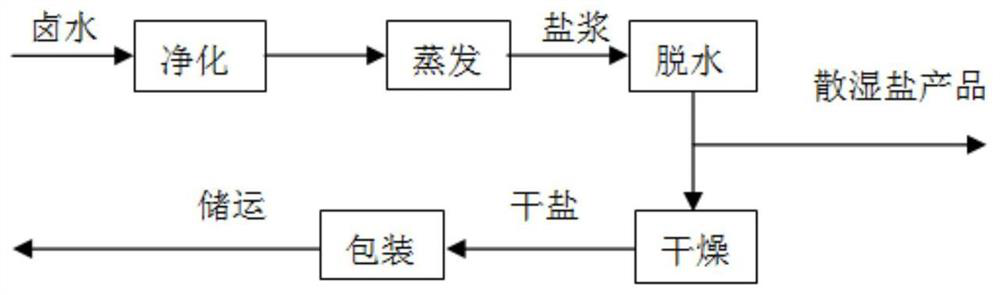

Wet salt cold drying anti-caking device and method

An anti-caking and cold-drying technology, applied in the direction of drying gas arrangement, drying solid materials, drying granular materials, etc., can solve the problems of ion membrane damage, potassium ferrocyanide toxicity, etc., to reduce moisture absorption and evaporation, fluidization Smooth, reduce the effect of sticking probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

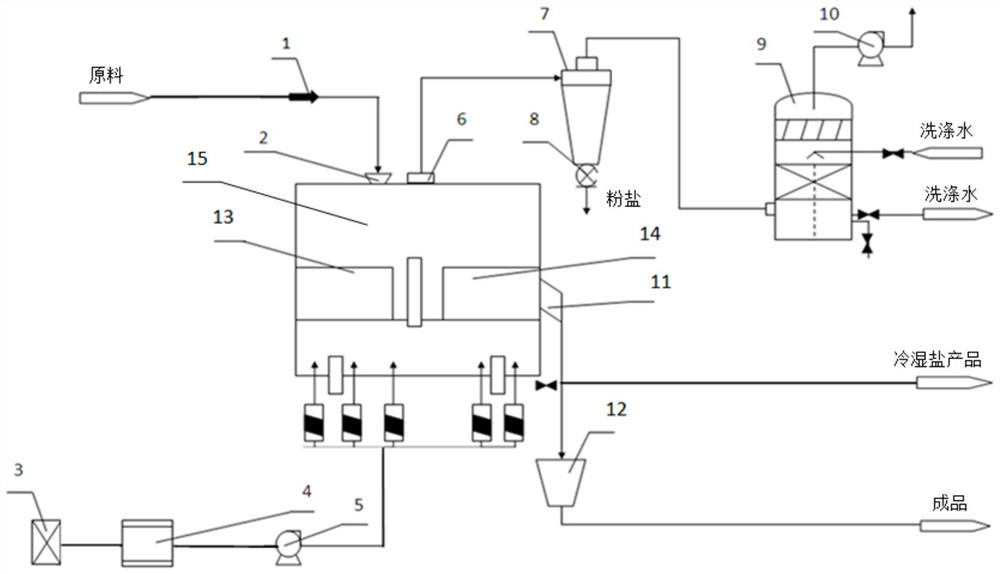

[0047] (1) Wet salt with a water content of less than 3% is transported to the fluidized bed by the conveyor belt and dispersed in the drying and cooling section of the fluidized bed. When the air temperature drops to 5°C and the relative humidity is 50%, the air blower is divided into five strands after gaining power (the pressure is 12Kpa), of which three strands enter the drying and cooling section I, and two strands enter the drying and cooling section II;

[0048] (2) The wet salt entering the fluidized bed is in a boiling state under the action of cold wind, heat transfer and mass transfer are carried out in the first section and the second section respectively, and the cooling and drying are completed. ), directly transported to the warehouse for shipment as a bulk industrial product;

[0049] (3) Tail gas after drying in the fluidized bed (sodium chloride content is 4g / Nm 3 ) enters the cyclone separator through the induced draft pipeline to recover powdered salt sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com