Slab end slotted hole SP hollow laminated slab-steel beam connecting structure and construction method thereof

A technology of connecting structures and slotting holes, which is applied to floors, building components, building structures, etc., can solve problems such as poor structural integrity and seismic performance, brittle damage at the joints of plate ends, and unreasonable structural force transmission, etc., to achieve Reduce construction difficulty, reduce mid-span deflection, and ensure continuity and integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing.

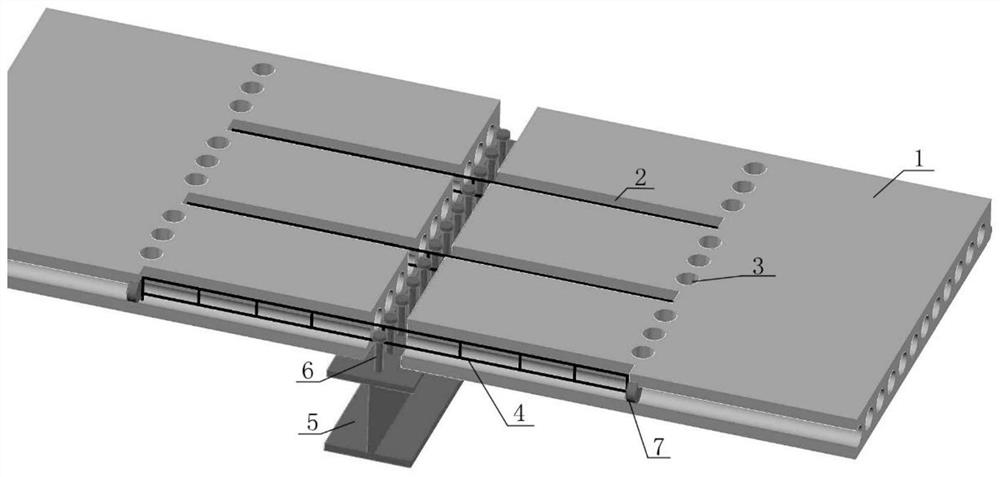

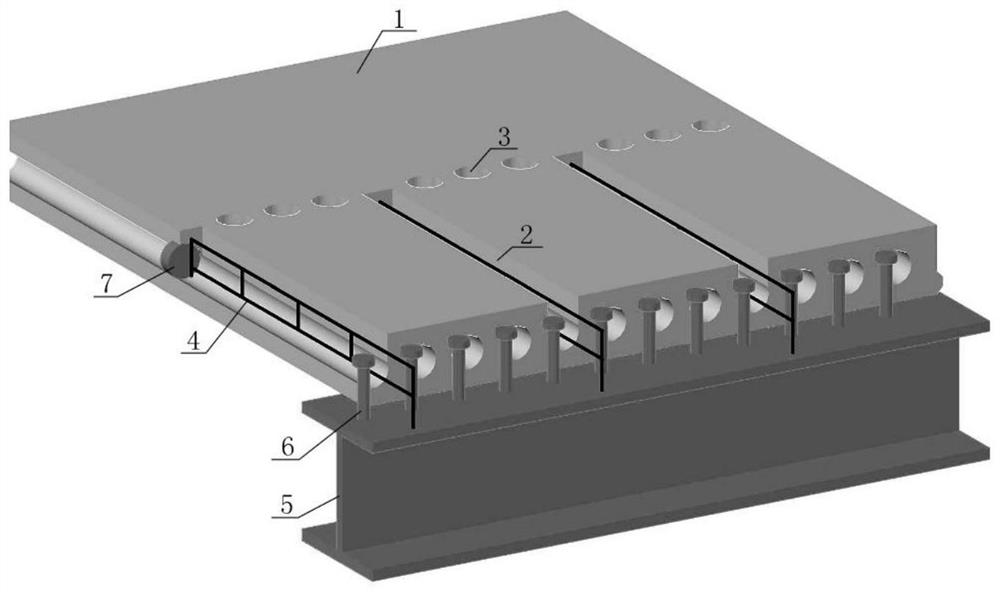

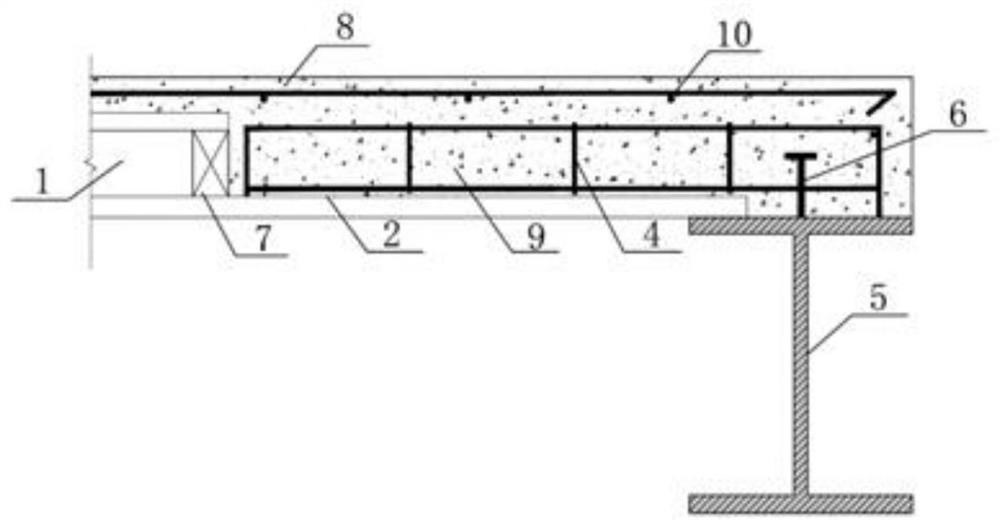

[0035] The SP prestressed hollow laminated slab combined floor beam-slab connection structure provided by the present invention mainly includes a SP prestressed hollow slab 1, a longitudinal reinforcement grid 4, a steel beam 5, a shear connector 6, Post-cast concrete layer 8, such as figure 1 , figure 2 , image 3 and Figure 4 shown.

[0036] Open the plate end groove 2 at the 1 / 4 core hole of the upper plate end of the SP prestressed hollow plate 1, and open the plate top hole 3 at the remaining core holes, and the opening position is aligned with the slot length, such as figure 1 , figure 2 and Figure 5 shown.

[0037] Set up the longitudinal steel grid frame 4 at the groove 2 of the plate end, and when it is a beam-slab connection at the side beam, it is spot welded and fixed with the steel beam 5 on site, such as figure 1 , figure 2 , image 3 and Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com