Organic silicon-fluorine modified single-component polyurethane waterproof coating and preparation method thereof

A polyurethane waterproof and fluorine modified technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of gaps, the effect is not as expected, and the tensile strength and tear strength are only 4MPa and 20N/mm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

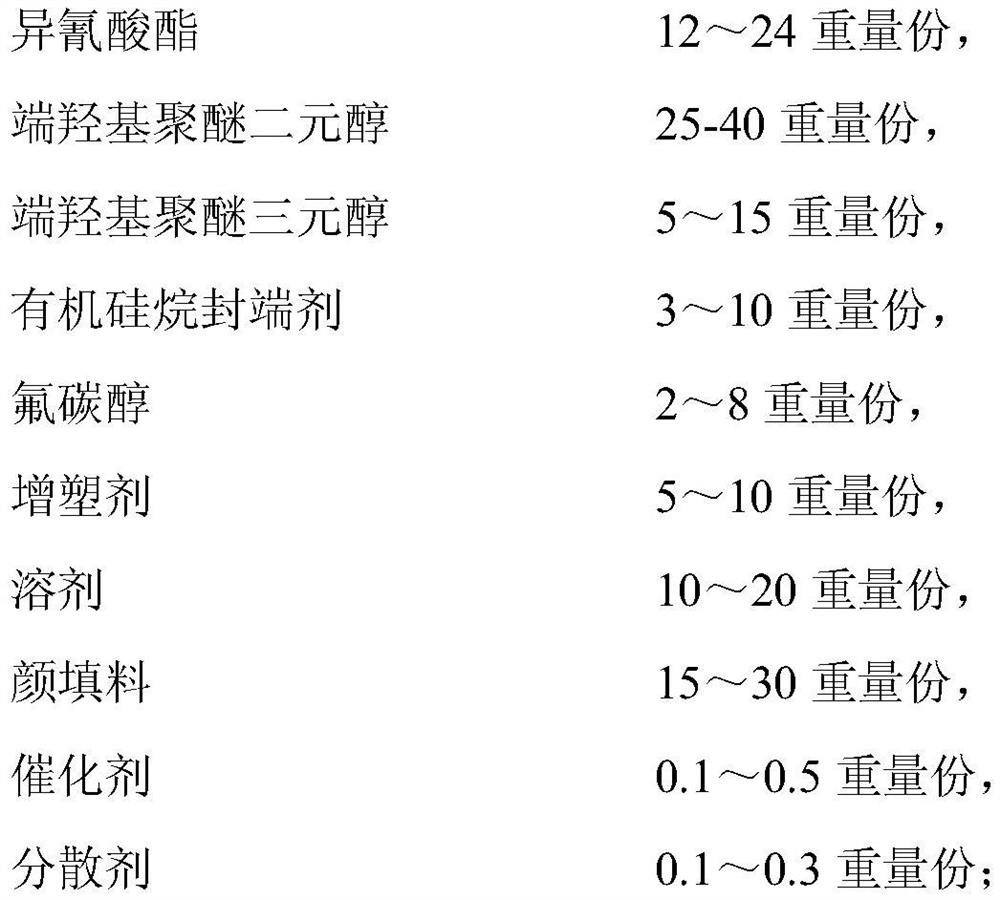

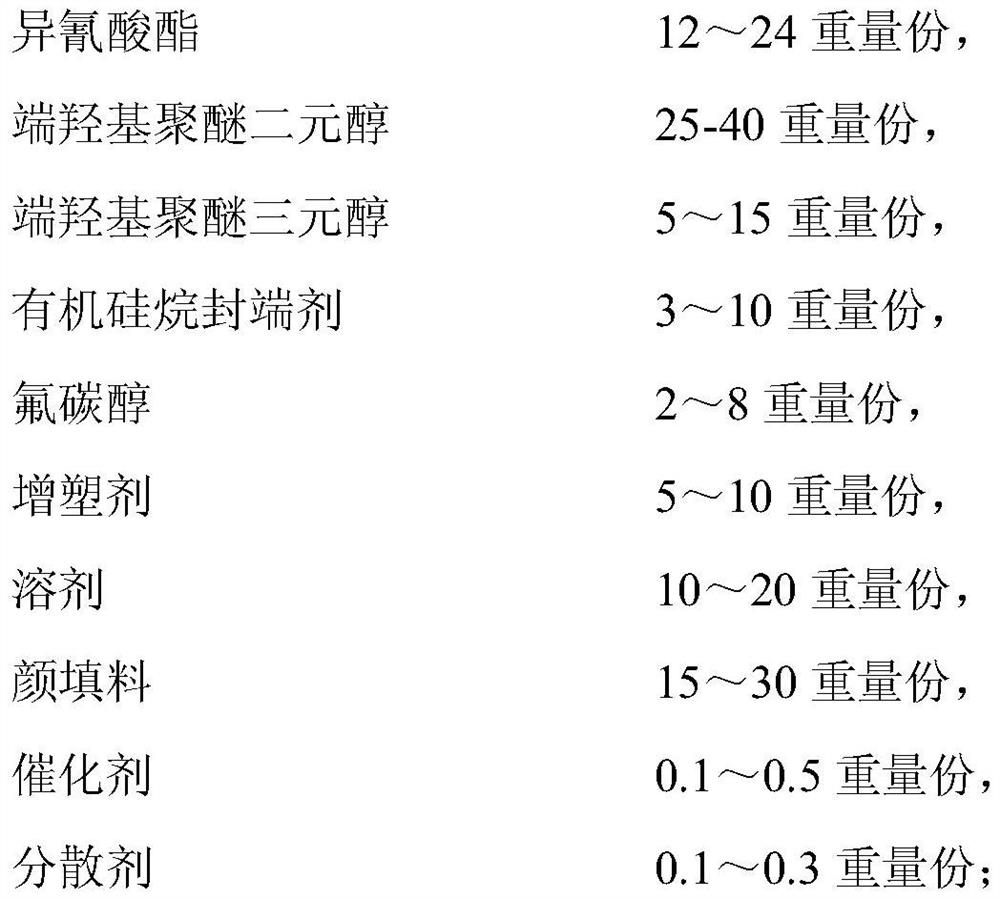

Method used

Image

Examples

Embodiment 1

[0033] Raw material ratio of modified polyurethane waterproof coating:

[0034] Diphenylmethane diisocyanate (MDI) 12 copies Polyether diol (molecular weight 1000, PPG type) 25 copies Polyether triol (molecular weight 3000, PPG type) 7.5 servings Organosilane capping agent (containing amino group) KH-550 4 parts Trifluoroethanol 2 copies Dioctyl phthalate (DOP) 7 copies Xylene 12 copies heavy calcium 29.9 servings carbon black 0.1 part Dibutyltin dilaurate (T-12) 0.2 parts Dispersant 0.3 parts

[0035] Process of modified polyurethane waterproof coating:

[0036] (1) Add 25 parts by weight of hydroxyl-terminated polyether diols and 7.5 parts by weight of trihydric alcohols, 7 parts by weight of dioctyl phthalate (DOP), 29.9 parts by weight of heavy calcium, and 0.1 parts by weight of carbon black in the reaction vessel part, stir and heat up to 100°C, and dehydrate for 2 hours under a vacuum o...

Embodiment 2

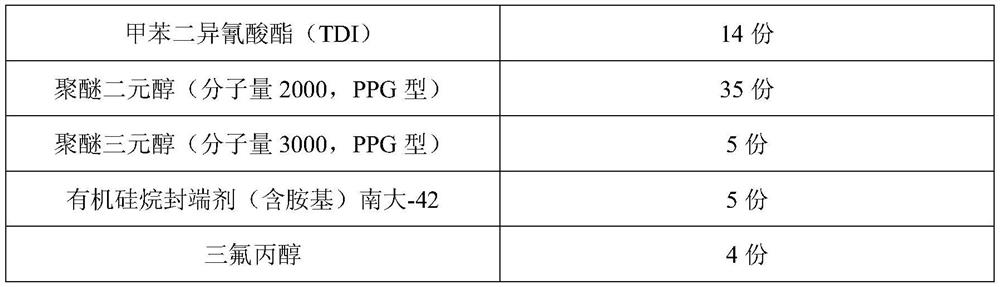

[0041] Raw material ratio of modified polyurethane waterproof coating:

[0042]

[0043]

[0044] Process of modified polyurethane waterproof coating:

[0045] (1) Add 35 parts by weight of hydroxyl-terminated polyether diols and 5 parts by weight of trihydric alcohols, 5 parts by weight of dioctyl phthalate (DOP), 15.9 parts by weight of heavy calcium and 0.1 parts by weight of carbon black in the reaction vessel part, stir and heat up to 120°C, and dehydrate under a vacuum of -0.1MPa for 3 hours;

[0046] (2) Lower the temperature to 80°C, add 0.3 parts by weight of dispersant and 14 parts by weight of toluene diisocyanate (TDI), and react for 3 hours under stirring at 85°C;

[0047] (3) Lower the temperature to 60°C, add 5 parts by weight of organosilane end-capping agent (containing amino groups) Nanda-42, raise the temperature to 80°C under stirring, react for 3 hours, then add trifluoropropanol while maintaining the temperature 4 parts by weight, continue to stir f...

Embodiment 3

[0050] Raw material ratio of modified polyurethane waterproof coating:

[0051]

[0052]

[0053] Process of modified polyurethane waterproof coating:

[0054] (1) Add 35 parts by weight of hydroxyl-terminated polyether diol and 5.5 parts by weight of trihydric alcohol, 5 parts by weight of diisononyl phthalate (DLNP), 14.9 parts by weight of talcum powder and 0.1 parts by weight of carbon black in the reaction vessel parts by weight, stirred and heated to 120°C, and dehydrated for 3 hours under a vacuum of -0.1MPa;

[0055] (2) Lower the temperature to 80°C, add 0.2 parts by weight of dispersant and 18 parts by weight of isophorone diisocyanate (IPDI), and react for 3 hours under stirring at 85°C;

[0056] (3) Lower the temperature to 60°C, add 5 parts by weight of organosilane capping agent (containing amino groups) KH-602, raise the temperature to 80°C under stirring, react for 3 hours, then add pentafluorobutanol while maintaining the temperature 6 parts by weight,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com