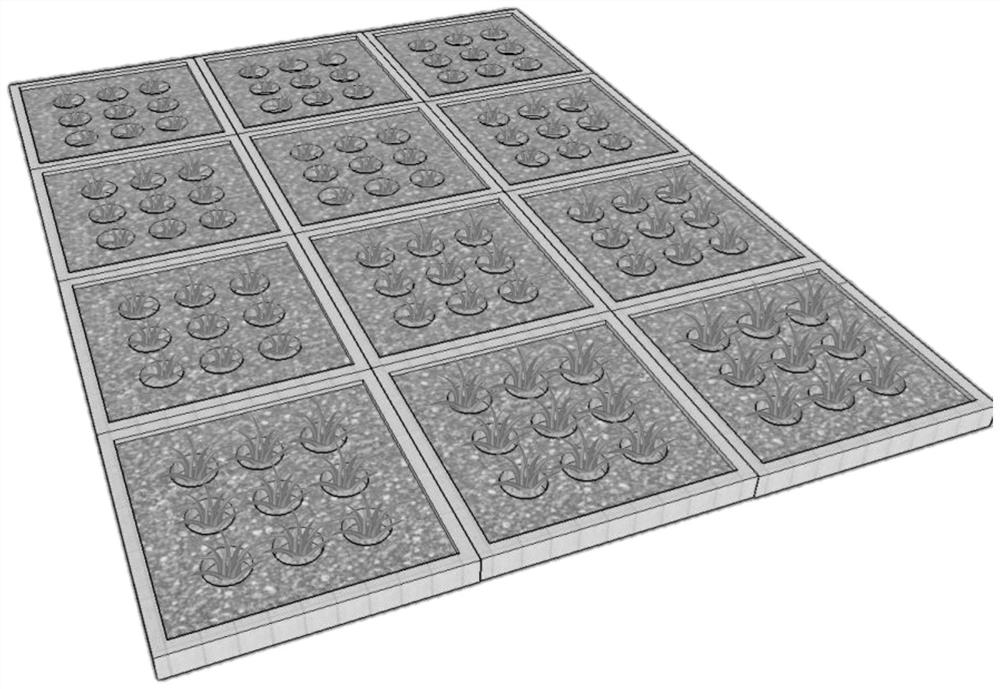

Planting type large-gap-reserved concrete as well as preparation method and application thereof

A technology of concrete and large voids, applied in the field of concrete, can solve problems such as unfavorable green planting, inconvenient replacement, small void ratio, etc., and achieve the effects of shortening planting time, reducing dust pollution, and preventing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

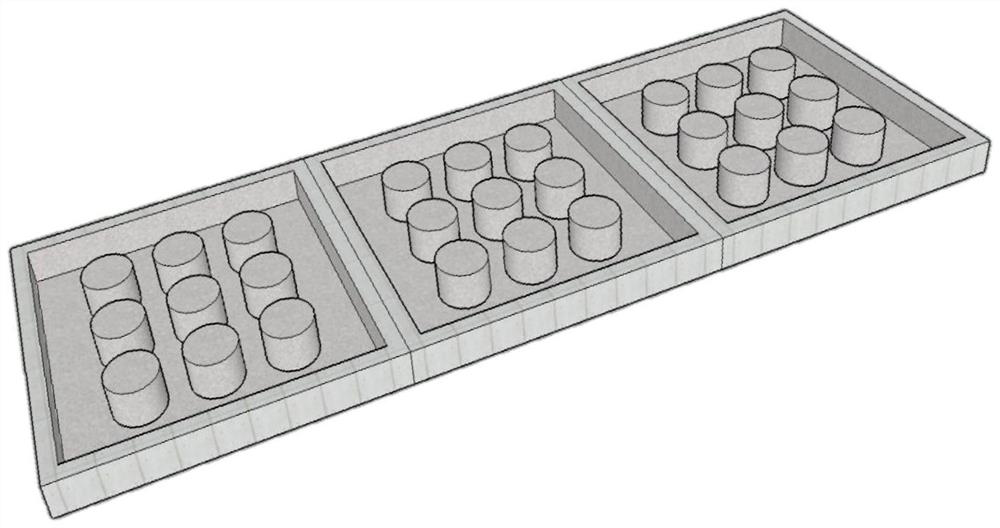

[0033] A method for preparing planting-type concrete with large voids reserved, comprising the steps of:

[0034] (1) Preparation of fermented coconut skin:

[0035] Coconut skin is pulverized and then bagged and added with water. The mass ratio of coconut skin and water is 1:0.5, and it is fermented at room temperature for 40d in a sealed state to obtain fermented coconut skin;

[0036] (2) Weighing: Weigh raw materials according to the following parts by weight: 80 parts of gravel; 20 parts of Portland cement; 0.5 parts of additives; 10 parts of fermented coconut skin; 5 parts of water, set aside;

[0037] The additive is mixed by 1 part of concrete surface enhancer, 3.1 parts of carboxylate, 0.8 part of sodium sulfate, and 1 part of iron sulfate;

[0038] (3) Mix crushed stone, Portland cement, additives, fermented coconut skin and water together, then put into the mold and form to obtain shaped concrete, and the shaped concrete is then cured to obtain planting type reserv...

Embodiment 2

[0042] A method for preparing planting-type concrete with large voids reserved, comprising the steps of:

[0043] (1) Preparation of fermented coconut skin:

[0044] Coconut skin is pulverized and then bagged and added with water. The mass ratio of coconut skin to water is 1:0.6, and fermented at room temperature for 35d in a sealed state to obtain fermented coconut skin;

[0045] (2) Weighing: Weigh raw materials according to the following parts by weight: 82 parts of crushed stone; 18 parts of Portland cement; 0.7 part of additive; 9 parts of fermented coconut skin; 8 parts of water, set aside;

[0046] The additive is mixed by 1.3 parts of concrete surface enhancer, 3.1 parts of carboxylate, 0.5 parts of sodium sulfate, and 2 parts of iron sulfate;

[0047] (3) Mix crushed stone, Portland cement, additives, fermented coconut skin and water together, then put into the mold and form to obtain shaped concrete, and the shaped concrete is then cured to obtain planting type rese...

Embodiment 3

[0051] A method for preparing planting-type concrete with large voids reserved, comprising the steps of:

[0052] (1) Preparation of fermented coconut skin:

[0053] Coconut skin is pulverized and then bagged and added with water. The mass ratio of coconut skin to water is 1:0.7, and fermented at room temperature for 30d in a sealed state to obtain fermented coconut skin;

[0054] (2) Weighing: Weigh the raw materials according to the following parts by weight: 85 parts of gravel; 15 parts of Portland cement; 1 part of additive; 5 parts of fermented coconut skin; 10 parts of water, set aside;

[0055] The additive is mixed by 1.5 parts of concrete surface enhancer, 3.1 parts of carboxylate, 0.3 parts of sodium sulfate, and 4 parts of iron sulfate;

[0056](3) Mix crushed stone, Portland cement, additives, fermented coconut skin and water together, then put into the mold and form to obtain shaped concrete, and the shaped concrete is then cured to obtain planting type reserved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com