Anti-erosion concrete admixture and preparation method thereof

A concrete admixture, anti-corrosion technology, applied in the direction of chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of erosion, material strength threat, increase cost, etc., achieve low addition amount, slow down the erosion process, increase The effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

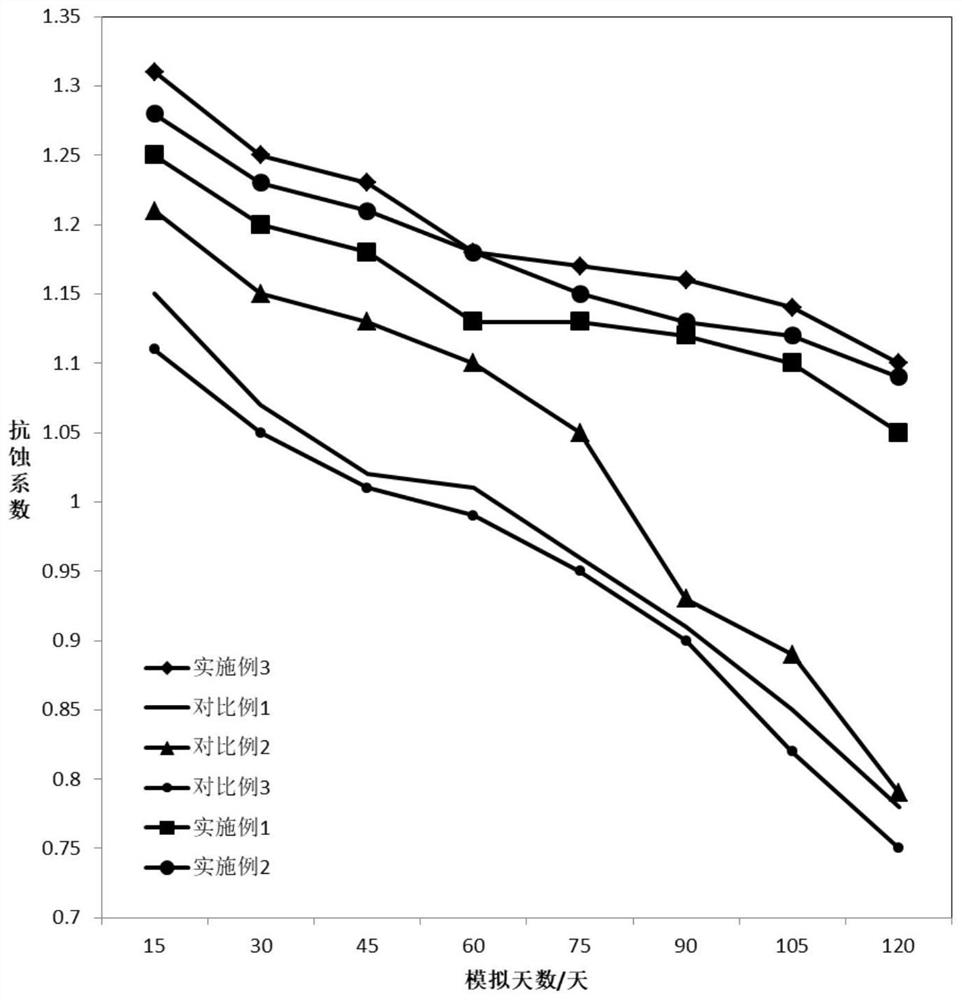

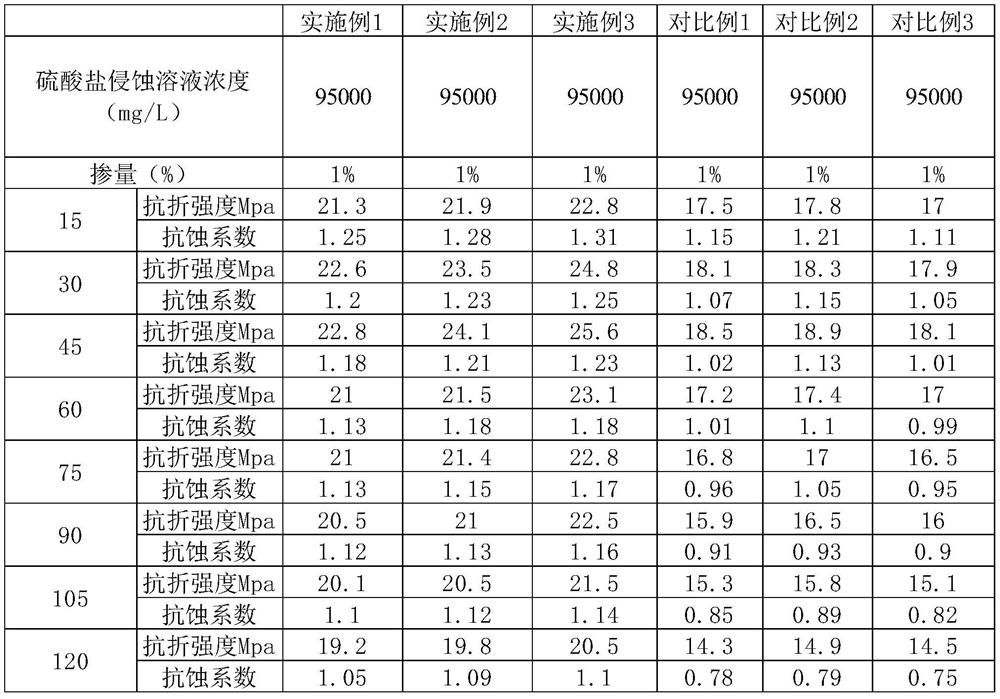

Examples

Embodiment 1

[0028] An anti-corrosion concrete admixture, prepared from the following raw materials in parts by weight: 30 parts of fly ash, 10 parts of ultrafine slag powder, 5 parts of modified expansion agent, 5 parts of water reducing agent, and 3 parts of grinding aid components share.

[0029] In this embodiment, the preparation method of the ultra-fine slag micropowder is as follows: put the blast furnace slag in a vertical mill for grinding for 30 minutes, then add the abrasive into the ball mill, add ethanol solution according to the ratio of material to liquid at 1:5, and then add the mass of the mixture 1% of cetyltrimethylammonium bromide was mixed and ball milled for 5 hours to obtain superfine slag powder.

[0030] In this embodiment, the specific surface area of the ultrafine slag powder is greater than 300m 2 / kg.

[0031] In the embodiment of the present application, the preparation method of the modified expansion agent is as follows: uniformly disperse bentonite into...

Embodiment 2

[0044] An anti-corrosion concrete admixture, prepared from the following raw materials in parts by weight: 40 parts of fly ash, 15 parts of ultrafine slag powder, 8 parts of modified expansion agent, 8 parts of water reducing agent, and 5 parts of grinding aid component share.

[0045] In this embodiment, the preparation method of the ultrafine slag micropowder is as follows: put the blast furnace slag in a vertical mill for grinding for 40 minutes, then add the abrasive into the ball mill, add ethanol solution according to the ratio of material to liquid at 1:5, and then add the mass of the mixture 1% of cetyltrimethylammonium bromide was mixed and ball milled for 5 hours to obtain superfine slag powder.

[0046] In this embodiment, the specific surface area of the ultrafine slag powder is greater than 300m 2 / kg.

[0047] In this embodiment, the preparation method of the modified expansion agent is: uniformly disperse bentonite into dimethyl diallyl ammonium chloride sol...

Embodiment 3

[0060] An anti-corrosion concrete admixture, prepared from the following raw materials in parts by weight: 50 parts of fly ash, 20 parts of ultrafine slag powder, 10 parts of modified expansion agent, 10 parts of water reducing agent, and 8 parts of grinding aid components share.

[0061] In this embodiment, the preparation method of the ultrafine slag micropowder is as follows: put the blast furnace slag in a vertical mill for grinding for 50 minutes, then add the abrasive into the ball mill, add ethanol solution according to the ratio of material to liquid at 1:5, and then add the mass of the mixture 1% of cetyltrimethylammonium bromide was mixed and ball milled for 5 hours to obtain superfine slag powder.

[0062] In this embodiment, the specific surface area of the ultrafine slag powder is greater than 300m 2 / kg.

[0063] In this embodiment, the preparation method of the modified expansion agent is: uniformly disperse bentonite into dimethyl diallyl ammonium chloride ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com